The Bakken is one of the most prolific plays in North America, but, even with the deployment of horizontal wells and hydraulic fracturing, anticipated recovery factors under primary depletion are usually in the range of 10 to 20%. Waterflooding has been a commonly deployed technology in conventional reservoirs to enhance recovery beyond primary depletion. However, the Bakken’s ultratight, largely oil-wet nature limits the potential of waterflooding. As an alternative, an optimally spaced well- to-well surfactant-flooding technology is proposed.

Introduction

Recent studies focusing on wettability alteration by use of surfactant in the Bakken have shown strong potential. Spontaneous-imbibition tests in Bakken cores show recovery factors that can exceed 30% and sometimes achieve up to 60%. However, in an ultralow- permeability system, the rate of surfactant imbibition is perhaps more important than the ultimate recovery factor. Initial studies show potential, but to achieve an economical surfactant recovery process, ultrahigh imbibition rates must be achieved. In addition to the technical challenges associated with stability, compatibility, and injectivity, economical deployment of surfactant in a marginally profitable play such as the Bakken is another major challenge. To minimize the surfactant required for a successful process, a surfactant would ideally have an ultralow critical micelle concentration (CMC) and low adsorption while maintaining key performance indicators that are discussed in the complete paper.

Experimental Methodology

Chemical- System Development and Qualification. This paper discusses a novel nonionic-surfactant production enhancer (PE) which is blended into a full chemical system (PE*). The nonionic chemical formulation of PE makes it highly compatible with the additives in the full fluid system such as corrosion inhibitor, scale inhibitor, and biocide.

Compatibility with the native fluids is also examined. Emulsion studies show that PE acts as a de-emulsifier, resulting in faster separation between Bakken oil and Bakken brine than can be achieved in its absence. PE is also highly suitable for operation in extreme conditions.

Corrosion inhibitor and biocide are included in the PE* formulation to mitigate any risk of wellbore corrosion or microbial activity, both of which could present a threat, particularly over long injection durations. Choline chloride as a clay stabilizer is also included in the full fluid system. Clay stabilizer is included in the formulation as a precautionary measure. Scale inhibitor is also included in the PE* formulation.

Chemical-System Performance. To evaluate recovery potential and imbibition rates, a series of spontaneous- imbibition tests was carried out using the PE and PE* formulations at varying concentrations to evaluate their performance potential. All tests were carried out on preserved core plugs from the Middle Bakken.

It is clear that PE performs substantially better than an alternative surfactant, which was selected to be representative of typical surfactants used in previous spontaneous-imbibition studies in the Bakken. It is also evident that surfactant has potential to accelerate water imbibition into Bakken core over brine alone.

In developing a surfactant-flood model, it is critical to understand at what concentration the surfactant system begins to impact the wettability and thus the relative permeability and capillary pressure behavior.

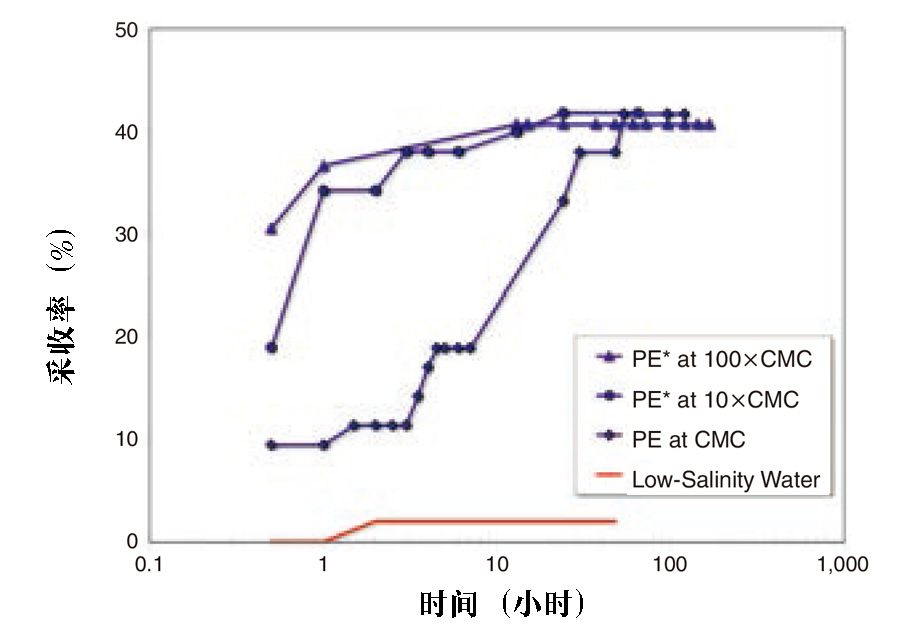

It is expected that the CMC will be even lower at reservoir temperatures near 115°C. The ultralow CMCs for PE indicate that PE may be effective even at low concentrations. This hypothesis is tested by investigating spontaneous imbibition of PE at varying concentrations. Fig. 1 shows recovery vs. time for a range of concentrations at 115°C. The base-case concentration starts near the CMC. As expected, similar recovery performance is displayed even at ultralow concentrations near the CMC. However, the rate of recovery is slower at concentrations near the CMC. To establish the threshold concentration above which the surfactant remains fully effective, the impact of adsorption must be taken into account. Static adsorption tests are carried out on a number of rock types using both cleaned and native-state samples in the presence of oil and brine. The adsorption data at known surfactant concentrations are then used in a history-match study of the low-concentration spontaneous- imbibition tests. Representative curves for surfactant adsorption vs. surfactant concentration are then developed along with surfactant-concentration thresholds for wettability alteration.

Reservoir Characterization

Horizontal wells are used to develop the Middle Bakken (reservoir properties are detailed in the complete paper). They are approximately 10,000 ft in length and often use multistage plug-and- perforation techniques, typically with 20 to 40 fracture stages. Hydraulic stimulations in the target area have traditionally been hybrid jobs, but the investigation presented in this paper will examine flooding potential between wells that have been completed with large slickwater jobs. Slickwater jobs discussed in this paper use approximately 150,000 bbl of water.

Natural-Fracture Characterization.

An integrated program consisting of logging, coring, pressure testing, and fluid tracing is used to gain insight into fault and fracture distribution in the target area of the Bakken for use in a surfactant-flooding reservoir model. Methodology of this program is detailed in the complete paper.

In total, approximately 100 natural fractures are identified in the horizontal core; however, a large percentage (approximately 40%) are found to terminate within the 29/16-in. -diameter core itself, indicating that most, if not all, of these fractures are likely small in scale. Another key observation is that a vast majority of the natural fractures identified have the same orientation. This indicates that even if they are areally extensive, they likely do not result in an extensively connected fracture network and, thus, would not contribute substantially to production. Overall, although many natural fractures are identified, it is believed on the basis of the core analysis that they are mostly small in scale and not extensively connected.

The lack of an extensively interconnected natural-fracture network is further supported by results of an extensive pressure- and fluid-communication program.

Hydraulic Fracture Characterization.

Pressure- and fluid-communication tests are also used to determine hydraulic-fracture properties. This approach is applied to evaluate the geometry of hydraulic fractures emanating from a Middle Bakken well completed with slickwater. The average fracture half-length in the analyzed area is determined to be 1,300 ft, with an approximate fracture height of 300 ft. It is important to note that the total fracture half-length is not completely filled with proppant and that the conductivity of the fracture varies with distance from the wellbore and drops below optimal conductivity approximately 1,000 ft from the well. Nevertheless, from an injection stand-point, this fracture half-length would yield significant hydraulic-fracture over-lap between Middle Bakken wells, but it would not allow for fractures to reach all the way to the adjacent wellbore.

Results and Discussion

Recovery Effect. By upscaling the laboratory-based, history-matched models and incorporating the field-scale fracture characterization, full-scale well-to- well models are developed to examine the potential of surfactant flooding in the Middle Bakken. The model includes two wells, with half-symmetry along the axes of the wells. Each well is hydraulically fractured and produced under primary production for approximately 12.5 years. The primary-production models generate realistic production curves, gas/ oil ratios, and water cuts for the target area. After 12.5 years, one of the wells is converted from a producer to an injector while the other well remains on production to simulate a pattern, line- drive, well-to-well flood. The production uplift is then modeled over 12.5 years of injection.

The most important sensitivity parameters for this recovery process are (1) fracture half-length and (2) overlap and adsorption. It is evident that the potential of a well-to-well flooding process is highly sensitive to fracture half-length (fracture overlap). Very limited overlap would not yield significant recovery uplifts within an economic time frame; however, even moderate hydraulic- fracture overlaps can yield significant recovery uplifts for surfactant flooding in the Middle Bakken. The second-most- critical sensitivity parameter for surfactant flooding the Middle Bakken is surfactant adsorption. If adsorption is too high, much of the surfactant will be lost near the injection-well fractures, and the ability to alter the wettability favorably will be limited. If, however, surfactant is able to propagate into the reservoir effectively and alter the wettability, as has been observed on the laboratory scale, the effect on recovery can be quite favorable.

Economic Evaluation. While models show technical potential for surfactant flooding to increase ultimate recovery in the Bakken, the economic viability of surfactant flooding must also be considered. An economic-sensitivity study that examines three economic scenarios is presented. The optimistic scenario assumes relatively high oil prices and low operational and capital costs, while the pessimistic scenario assumes the opposite. In the optimistic case, a credit is given for the reduced water-disposal costs that would otherwise be incurred. All three models assume the same water-injection and oil-recovery profiles used in the medium-adsorption case with the base-case fracture half-lengths of 1,400 ft. Both the base-case scenario and the optimistic economic scenario show very favorable economics from both a return-on-investment and a rate- of-return perspective. In the pessimistic scenario, with sustained low oil prices, high chemical costs, high operational and capital costs, and no credit for reduced water-disposal costs, the economics are not favorable. The likelihood of operating a surfactant flood in the Bakken in that environment, however, is very low.

石油圈

石油圈