KRYPTOSPHERE ultra-conductive ceramic proppant technology is engineered to maximize hydrocarbon flow rates throughout the life of the well.

This step-change technology is available as low-density and high-density ceramic proppant to suit your well conditions and field economics.

Engineered for today’s production enhancement challenges

KRYPTOSPHERE ultra-conductive ceramic proppant technology delivers increased production, recovery and return on investment from any reservoir.

In a market where every barrel of production is critical, the technology enables you to realize the reservoir’s production potential while lowering finding and development cost per BOE.

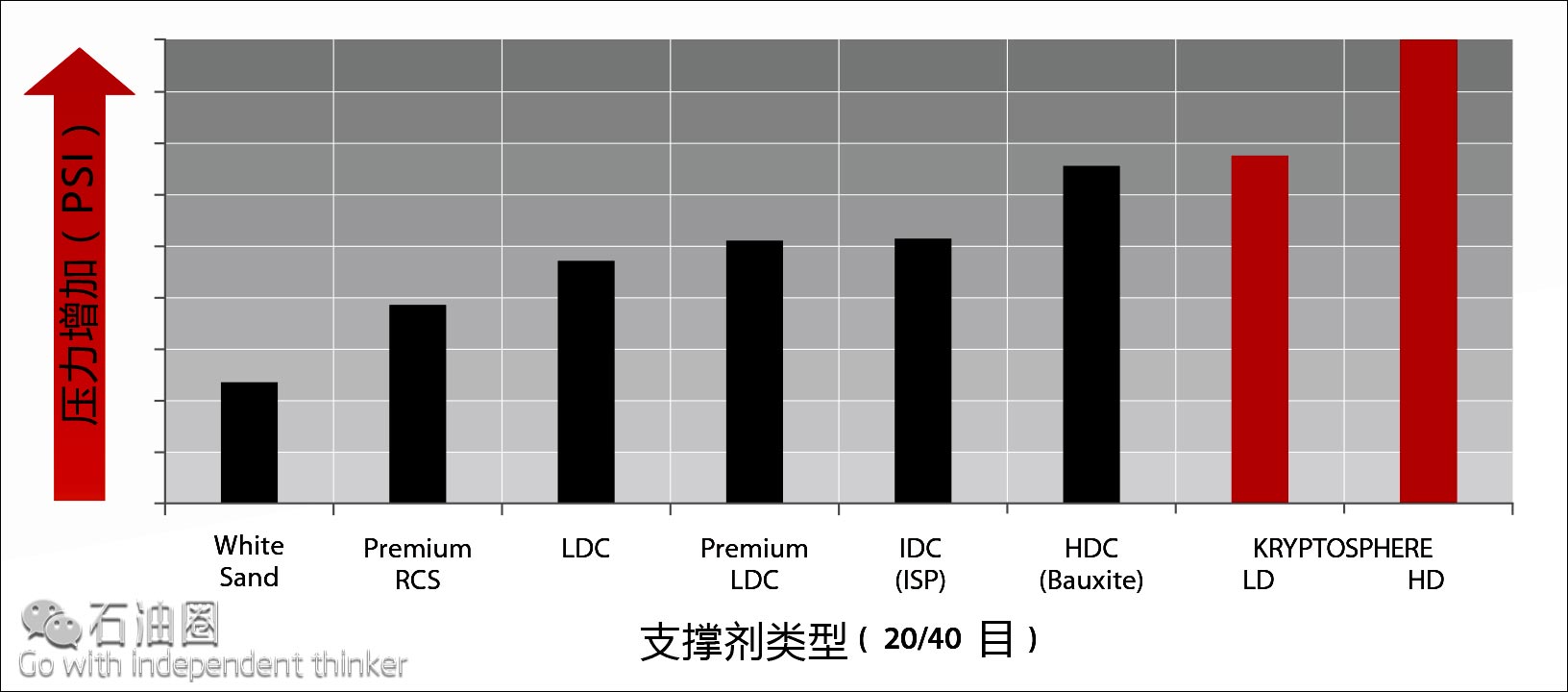

A step-change in conductivity, strength and durability

By engineering the physical characteristic that enhances production performance, CARBO has produced an ultra-conductive ceramic proppant that provides a step-change in conductivity, compressive strength and durability.

More space to flow

Our unique KRYPTOSPHERE technology builds more space to flow® into every fracture and sustains it for longer. The technology has a high crush-resistance and withstands stress-cycling to ensure that fracture conductivity, integrity and connectivity are sustained long-term to optimize production.

Increase production, EUR and ROI in all reservoir conditions

Available as a low-density (LD) and high-density (HD) ceramic proppant, KRYPTOSPHERE technology enables you to build the optimal balance of contact, conductivity and durability required to improve the production and economic performance across the entire range of low to ultra-high closure stress conditions.

Engineered for exceptional production and economic performance

The physical characteristics of KRYPTOSPHERE technology have been engineered to provide unmatched long-term conductivity and durability. The result is a proppant that outperforms all others.

A step-change in performance

Both KRYPTOSPHERE LD and HD technologies maintain higher levels of conductivity at higher closure stresses than sand and conventional ceramic proppant.

Outperforms conventional ceramic proppant

The unique engineering of KRYPTOSPHERE technology yields higher levels of performance than conventional ceramic proppant.

Features

Superior shape for enhanced conductivity

The high sphericity and roundness of every proppant grain increases conductivity and improves the flow profile through the propped fracture, which leads to higher production rates and increased EUR.

Exceptional strength for increased durability

The low internal proppant porosity increases crush-resistance and durability. As a result, longterm conductivity is improved and sustained for longer even after stress-cycling.

Highly smooth to improve flow and reduce erosion to equipment

A highly smooth proppant surface means that erosivity is reduced, which protects surface and downhole equipment during hydraulic fracturing operations. The proppant also has a low beta factor and reduces the pressure drop experienced across the fracture by minimizing non-Darcy flow effects.

Uniform size for optimal proppant packing

KRYPTOSPHERE technology is a single mesh size product that can be manufactured to meet your fracture design and reservoir requirements.

The uniform size, combined with the superior shape, results in optimal proppant packing, which improves fracture conductivity.

Build the optimal propped fracture in any reservoir

The choice of low- and high-density technologies enables you to build propped fractures with the optimal balance of contact, conductivity and durability for your well.

Precisely engineered to your well conditions

KRYPTOSPHERE technology is manufactured to a single mesh size so it can be produced at the optimal size for your fracture design and reservoir conditions. The choice of low- and high-density technology means that you can perfectly balance reservoir contact, closure stress, economic and pumping considerations to design the optimal fracture for your well.

Lower beta factor and pressure drop

The spherical, smooth and uniform size characteristics of the technology results in more consistent flow paths and minimizes the pressure drop due to non-Darcy flow effects across the fracture. This further enhances flow rates and ultimate recovery.

Optimal proppant packing

KRYPTOSPHERE technology provides more space to flowin the proppant pack, as the uniformly-sized proppant with superior roundness enables optimal packing in the fracture. The irregular size and shape of sand and lower-quality ceramic proppant result in a tight proppant pack that reduces the space for flow and conductivity, which is further impaired as proppant integrity fails and creates fines.

Exceptional microstructure for increased strength and durability

KRYPTOSPHERE technology is engineered to have exceptional compressive strength and durability, which delivers increased long-term conductivity in realistic downhole conditions.

Build increased production and recovery into every fracture

The unique KRYPTOSPHERE technology manufacturing process creates a proppant with a low internal porosity. The result is a proppant with increased compressive strength, high durability and improved crush-resistance, which can withstand the most demanding reservoirs and stress-cycling conditions. By building higher long-term conductivity into every fracture and sustaining it for the longer production, EUR and ROI are maximized.

Engineered to outperform all other proppant

KRYPTOSPHERE technology outperforms conventional proppant, which has a higher and irregular distribution of internal porosity, leading to voids that reduce compressive strength and durability. This causes the integrity of the proppant to fail as closure stress increases or under stress-cycling which results in fines that reduce fracture conductivity and may lead to complete or partial loss of fracture connectivity.

Increased acid resistance and fracturing fluid compatibility

The high quality of materials and the precision manufacturing process used for KRYPTOSPHERE technology improves acid resistance, ensuring increased proppant durability and compatibility with production chemicals.

Enhanced production and economic performance in any reservoir

Low-density and high-density technology variants mean that the optimal balance of contact, conductivity and durability can be achieved cost-effectively in any reservoir.

Low density for lower costs per BOE and increased recovery

KRYPTOSPHERE LD ultra-conductive, low-density ceramic proppant technology has been developed to provide the highest levels of production and recovery across the entire range of low and high stress conditions.

The technology significantly exceeds the conductivity, compressive strength and durability of existing low-density proppant. In addition, the KRYPTOSPHERE LD technology provides comparable and, in many cases, higher conductivity than intermediate-density and bauxite ceramics while delivering improved proppant transport and increased propped fracture volume.

As a result of the higher quality and quantity of reservoir contact achieved, the technology increases flow rates, recovery and return on investment, thereby lowering F&D costs per BOE. The improved transport characteristics also reduce gel loading and pumping requirements to further reduce total fracturing costs.

High density for increased recovery in ultra-high closure stress and high risk environments

KRYPTOSPHERE HD ultra-conductive, high-density ceramic proppant technology has been specifically engineered for high closure stress and risk environments, including ultra-deepwater regions such as the Gulf of Mexico.

As the only proppant suitable for ultra-high closure stress environments, our high-density variant of the technology provides a step-change in conductivity, compressive strength and durability: significantly outperforming any other proppant available.

The development of KRYPTOSPHERE HD technology was in direct response to an operator’s request for a proppant that could deliver new levels of conductivity at >14,000 psi closure stresses.

Significantly less erosive to downhole equipment

The high sphericity and smoothness of KRYPTOSPHERE technology means it is significantly less erosive during pumping. As a result, equipment wear is reduced and fracture design constraints, due to erosivity concerns, are removed: enabling higher proppant volumes to be used.

Integrated production enhancement solutions

The conductivity, compressive strength and durability of KRYPTOSPHERE technology provides an ideal platform for the delivery of proppant-delivered production enhancement solutions.

石油圈

石油圈