MicroSeismic宣布完成世界最长微地震监控系统—BuriedArray的安装,该系统与其它微地震监控系统相比具有成本低、效率高和适应性强的特点。目前已广泛用于压裂裂缝的监控和评估。

MicroSeismic公司 宣布完成世界上最长的永久性近地表微地震监控系统BuriedArray的安装。该装置将用于美国Louisiana(路易斯安那州)地区Haynesville构造的完井监控,覆盖面积达15平方英里,包含99个工作站。

BuriedArray安装于2010年,目前仍处于运行状态,已为三家勘探开发公司提供水力压裂监控服务,累计监控10口井,129个压裂段数。目前,该系统所有权和使用权归Sabine Oil & Gas公司所有,用于多井重复压裂活动的监控和评估。

在低成本策略的驱动下,Sabine在Haynesville进行的包括BuriedArray在内的收购对自身非常有利,同时更具吸引力。Sabine Oil and Gas资产开发部的高级副总裁Cheryl Levesque表示:“我们将利用BuriedArray微地震分析技术对新型重复压裂方法进行评估,并确定收益最高的重复压裂策略。”

“投入使用至今的五年中,BuriedArray已为多家勘探开发公司提供了有效服务,并将在未来更长的时间里继续帮助客户评价储层改造的效果,对此我们感到十分自豪。BuriedArray作为一个经济、贯穿油藏开发周期且低成本的实时激活的监控系统,非常符合我们的理念。” MicroSeismic的运营高级副总裁Randy Evans表示。

迄今为止,MicroSeismic已安装的BuriedArray系统超过50台,对2个州的230口井进行了超过15000个压裂段的监控。

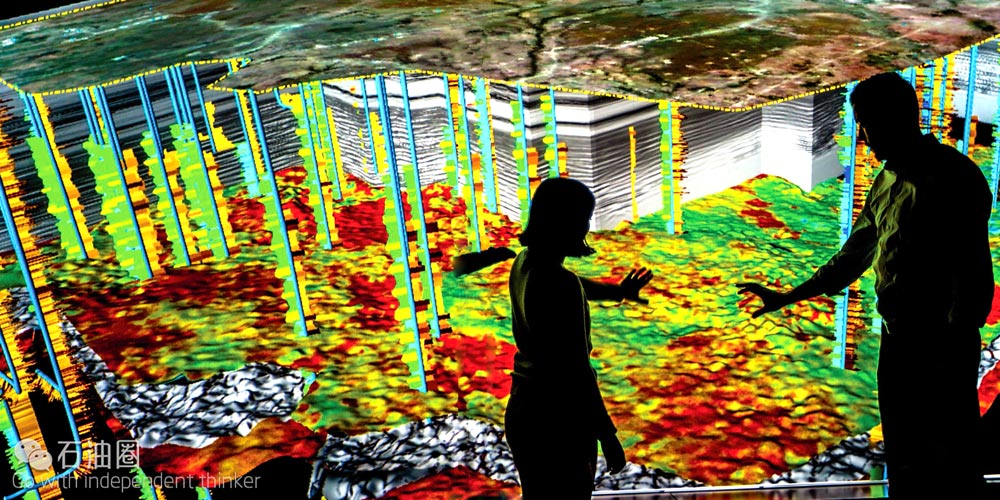

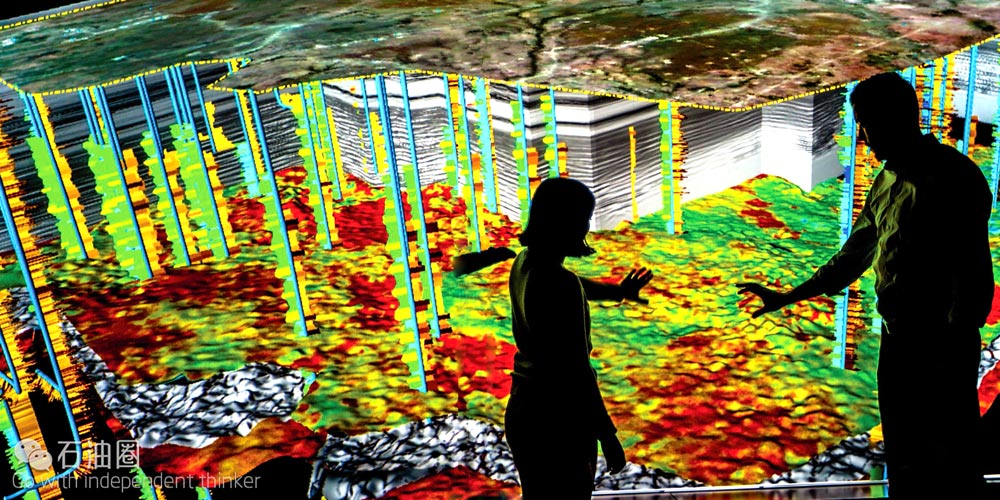

MicroSeismic的BuriedArray数据采集系统通过将多个专门设计的检波器进行永久性排列组合,并安装在近地表以监控较大范围内的储层水力压裂和重复压裂操作过程,及诱发的地震活动。

一旦安装完毕,BuriedArray系统通过已经授权专利的PSET技术,监控储层改造过程中裂缝拓展情况,以提高产能并改善储层改造效果。该系统通过电池、太阳能和风能供电,可全天候不间断运行,启动或关闭简单易行。系统采用完全定制模式,监测区域超过500平方英里。

永久性&实时浅层监控系统石油圈原创www.oilsns.com

MicroSeismic公司的BuriedArray数据采集系统通过将本公司设计的检波器进行永久性排列组合,并安装在近地表,对超过500平方英里的区域进行监控。BuriedArray永久性&实时浅层监控系统采用PSET技术,监控油井增产作业过程中裂缝的拓展情况。通过对震源机制的测定,PSET技术使得压裂增产措施更加高效。

BuriedArray便于操作人员同时监控多口井或者单井的整个开发周期,系统具有较宽的监控范围,有利于形成规模效益。随着越来越多的油井通过BuriedArray进行监控,费用相比其它微地震数据采集技术显著减少。BuriedArray系统利用相同的设备进行大范围重复监控的特点,更有利于油田进行战略规划、开发以及重复压裂裂缝监控等。

排列设计石油圈原创www.oilsns.com

根据建立的噪声剖面,BuriedArray在不同深度下安装包括1C 和3C检波器的多层次组合。工作站的密度随所需监控能力的不同而不同,每平方英里2-8个不等。浅埋藏检波器通常可使表面噪声降低超过20分贝,因此工作站间距可设置稀疏以降低成本。BuriedArray工作站通过电池、太阳能和风能供电,可以全天候工作。监测数据可以被记录在本地或无线传输到主处理单元。

主要优势石油圈原创www.oilsns.com

1.快速确定局部应力方向;石油圈原创www.oilsns.com

2.观测油田增产措施效果;

3.通过长期生产监控,确定单井和多井区的泄油面积;

4.同时监控多层和多井;石油圈原创www.oilsns.com

5.优化加密井井排井距,提高生产效率;

6.永久性排列提供了折射监控功能;

7.全天候不间断监控。

企业简介石油圈原创www.oilsns.com

MicroSeismic公司是一家专业提供非常规油气藏完井评估和水力压裂实时监测服务的油田服务公司。该公司成立于2003年,率先采用表面微地震监控技术,用于接收储层水力压裂改造过程中产生的自然、低能量地震信号。通过对地表、近地表和井下数据的分析,MicroSeismic帮助油气公司评价储层改造的技术效果和带来的经济效益。

来自/MicroSeismic 译者/丁志莹 编辑/王亚钒

MicroSeismic Inc. has announced that it has achieved the longest-installed active, permanent, near-surface array in the world. This BuriedArray® was installed to monitor completions in the Haynesville formation in Louisiana and includes 99 stations covering 15 square miles.

Installed in 2010, the BuriedArray is still active and has monitored hydraulic fracturing operations for three different exploration and production (E&P) companies, totalling 10 wells and 129 treatment stages monitored to date. Currently, the system is owned and operated by Sabine Oil & Gas to monitor and evaluate refracturing activities for multiple wells.

“With cost-saving initiatives driving our current strategies, it is advantageous for Sabine that our recent Haynesville acquisition includes a BuriedArray, which made the property even more attractive. We are using microseismic analysis provided from the BuriedArray to evaluate new refracturing methods and confirm the most profitable refracturing strategy going forward,” said Cheryl Levesque, Senior Vice President, Asset Development, Sabine Oil and Gas.

“We’re proud that this particular BuriedArray has been helpful to multiple E&P companies and continues, five years after installation, to help these partners understand reservoir treatment effectiveness. This is a perfect illustration of our vision for the BuriedArray, to act as a cost-efficient, life-of-field monitoring system that can conveniently be activated at any time with very little cost or effort,” said Randy Evans, Vice President of Operations, MicroSeismic.

To date, MicroSeismic has installed over 50 BuriedArray systems, monitoring more than 15 000 stages for 230 wells on 2 continents.

MicroSeismic’s BuriedArray data acquisition system deploys a permanent array of multiple custom-designed geophone strings installed near surface and spread across a wide area to monitor a reservoir during hydraulic fracturing and refracturing operations or to monitor induced seismicity.

Once installed, the system shows how fractures are propagating during the treatment of each well to improve productivity and treatment efficiency using patented PSET® technology. Powered by battery, solar, and wind sources, BuriedArray is able to run 24/7 and can easily switch on or off. The system is fully customisable and can be built to monitor areas as large as 500 square miles.

Permanent & Real-Time Shallow Subsurface Monitoring

BURIEDARRAY®

MicroSeismic’s BuriedArray data acquisition deploys a permanent array of MicroSeismic-designed geophone strings installed in the near surface to monitor an area of more than 500 sq. miles (1,300 sq. km). BuriedArray Permanent & Real-Time Shallow Subsurface Monitoring uses PSET® technology to provide results that show how fractures are propagating during the well treatment. By determining source mechanisms, PSET processing provides a greater understanding of the effectiveness of the stimulation treatment.

BuriedArray is ideal for operators who need to monitor multiple wells or require monitoring through the life-of-field. The wide area coverage provides economies of scale. As more wells are monitored under the same array, costs decline dramatically relative to any other microseismic acquisition techniques. The ability to monitor large areas repeatedly with the same equipment leads to more strategic field planning and development, and the ability to monitor refracs.

Array Design

The BuriedArray installs include multiple level combinations of 1C and 3C phones at depths varying according to the established noise profile. The density of stations will also vary based on event detectability; from two to eight stations deployed per square mile. Shallow burial of phones typically reduces surface noise more than 20 dB allowing sparser station spacing, reducing cost. BuriedArray stations can be live 24/7 as they are powered by battery, solar, and wind sources. Data can be recorded locally or transmitted wirelessly back to the main processing unit.

Key Benefits:

Directly map local stress orientations

Observe field-wide well stimulation

Map individual and multiple well drainage areas with long-term production monitoring

Monitor multi-zones and multi-wells simultaneously

Optimize infill well spacing and lateral length for increased production efficiency

Permanent array provides refract monitoring capabilities

Ideal for 24/7 time lapse monitoring applications

ABOUT MS

MicroSeismic, Inc. is an oilfield services company providing completions evaluation services and real-time monitoring and mapping of hydraulic fracture operations in unconventional oil and gas plays.

Founded in 2003, MicroSeismic invented the use of surface microseismic monitoring to listen to the naturally occurring, low-energy seismic noise emitted from a reservoir during hydraulic fracturing stimulation. Utilizing surface, near-surface, and downhole arrays, MicroSeismic helps oil and gas companies understand how the reservoir responds to stimulation and its impact on customer economics.

未经允许,不得转载本站任何文章:

-

- 柠檬

-

石油圈认证作者

- 毕业于中国石油大学(华东),油气井工程硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系我们。

石油圈

石油圈