IMaxTM and IMax+TM bits drill faster and last longer through hard and abrasive formations. The impregnated diamond matrix bits are a highly flexible series that allow materials and designs to be quickly adjusted to the requirements of a specific application. The result is optimal drilling performance in very challenging formations.

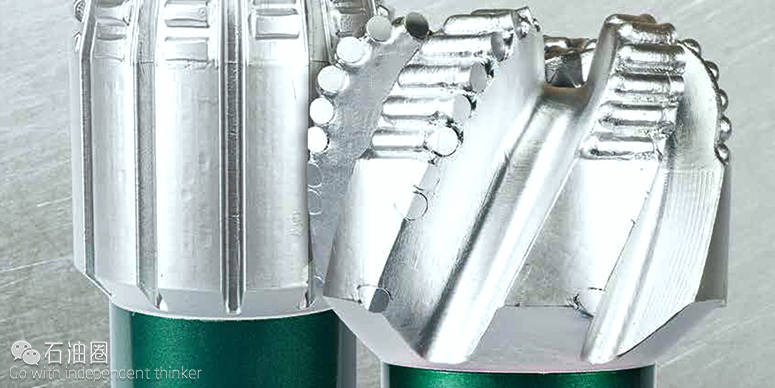

IMax bit cutting structures feature cylindrical, hot isostatic pressed (HIP) segments tailored to the formation. IMax+ designs also incorporate PDC cutters for a hybrid bit ideal for drilling from a softer formation into harder rock formations where durability is key.

IMax+ PROVIDES HYBRID PERFORMANCE

IMax+ adds premium Vulcan® PDC cutters for a hybrid design with a dual cutting structure. The bit design is particularly effective in less-consolidated sandstones or when drilling from a softer formation into a harder and more abrasive formation. Drilling with the IMax+ optimizes performance and avoids a trip to change bits.

The PDC cutters are placed on the face of the HIP segments for increased formation shearing. As the formation becomes harder or more abrasive, the PDC cutters wear down to expose the HIP cutting structure to the formation.

DIAMOND SELECTION AND MATRIX DISTRIBUTION ARE CRUCIAL

High-performance IMax and IMax+ bits are based on the latest in design, material and manufacturing science. Varel begins with a strict diamond selection process to ensure each area of the bit utilizes diamonds of similar size and quality.

The diamonds are then pelletized. Pelletization prevents diamond aggregates and reduces areas of low diamond concentration for a more uniform stone distribution within the matrix material. This process improves diamond/matrix bonding which results in a more consistent wear pattern during the bit run.

The same process is followed in manufacturing the HIP segments that form the bit’s cutting elements. These segments undergo a sintering process to achieve reduced porosity. The finished HIP segments are then positioned in the bit blades in specific patterns determined by Varel’s proprietary SPOTTM bit design program. The high segment standoff improves fluid flow for better bit face cleaning and cooling action.

A proprietary controlled-atmosphere infiltration process is then applied to the entire bit. The controlled temperature environment reduces oxidation and graphitization to improve bit wear characteristics and durability.

Superior hydraulics

For optimum hydraulics, Varel impregnated bit designs undergo extensive computational fluid dynamics (CFD) evaluations to ensure a configuration that eliminates re-grinding and re-circulation of drilled cuttings — a common occurrence when drilling hard and abrasive applications. The sophisticated CFD process identifies and eliminates possible stagnation zones, resulting in a hydraulics configuration that improves cleaning efficiency, segment and cutter cooling, and ROP. Segment standoff also improves fluid flow.

Clear, intelligent nomenclature

The Varel impregnated bit is designated as VI, with a DGX suffix describing bit features. For example, the VI1213DGX designates a Varel impregnated bit with 12 blades and 13 mm diameter HIP segments.

The DGX suffix describes drop-in (D) cutters in the gauge pad, TSP gauge (G) and tungsten carbide shock studs (X). IMax+ uses the same convention with the addition of the plus (+). Thus, a VI+613DGX would be a Varel impregnated hybrid bit with six blades, 13 mm PDC cutters and the same DGX features as the first example.

Design Software

IMax bits are designed using advanced analytical tools. The SPOT bit design program provides a collaborative environment where bit designers, field engineers and other stakeholders can fully engineer a specific bit design for optimal performance and steerability using particular drilling systems. Using advanced algorithms, rock mechanics analysis and extensive field operating and performance data directly from the rig, the SPOT program manages large volumes of data and enhances interpretation.

In conjunction with Varel’s proprietary GeoScienceTM rock analytics program, SPOT makes it possible to determine how changes in bit features and dimensions will affect steerability, bit walk,

DLS capability and vibration control for any well trajectory and BHA.

Because the design process allows the team to select the most appropriate design elements,cutting structure design that is always optimized for the application.

DELIVERING BEYOND BENCHMARK PERFORMANCE IMax DIAMOND-IMPREGNATED BIT SETS PERFORMANCE RECORDS WITH DEBUT APPLICATION IN BOLIVIA

In its initial application in Bolivia, where hard and abrasive formations limit ROP and accelerate bit wear, a Varel 6″ (153.25 mm) diamond-impregnated bit VI1213DGX set new performance records in both footage and ROP to achieve the lowest cost per foot for the slim hole section.

The design of the VI1213DGX impregnated bit was customized for turbine drilling in the formation’s sandstone and naturally fractured quartz. The objective was to drill as much footage as possible from 5,206 m (17,080 ft) measured depth while maintaining a competitive ROP.

The bit drilled 430 m (1,410 ft) in a single run, increasing footage drilled by 120% compared to the previous-best 6″ run. An average ROP of 2.43 m/h (8 ft/hr) was 30% faster than the ROP of the next-longest run.

This single-run performance exceeded all previous 6″ (153.25 mm) runs in Bolivia, establishing new footage and ROP records to deliver the lowest cost per foot. When the bit was pulled due to MWD hours, it was dull-graded: 2-2-WT-A-X-I-BT-DTF, RE-RUNNABLE.

NEW 5-5/8″ IMax BIT SETS PERFORMANCE RECORDS IN OMAN

A 5-5/8″ (142.875 mm) IMax VI1213G delivered outstanding performance in Oman, drilling 249 m (817 ft) through an abrasive mixture of sandstone, siltstone, shale, silicilyte and limestone in the Mushwar field. This is as much as seven times the interval drilled by similar bits in the same well and three times the ROP.

RECORD: 6″ IMax BIT DRILLS FARTHER AND FASTER THAN OFFSETS IN ALGERIA

In Algeria’s abrasive Silurian-Gedinian sandstones, a Varel 6″ (153.25 mm) VI1213G drilled 309 m (785 ft) to exceed the best offset performance, with 7% more footage and 8% faster ROP. The bit not only exceeded all offset runs, but the dull condition was much better than average with very even wear across the face.

石油圈

石油圈