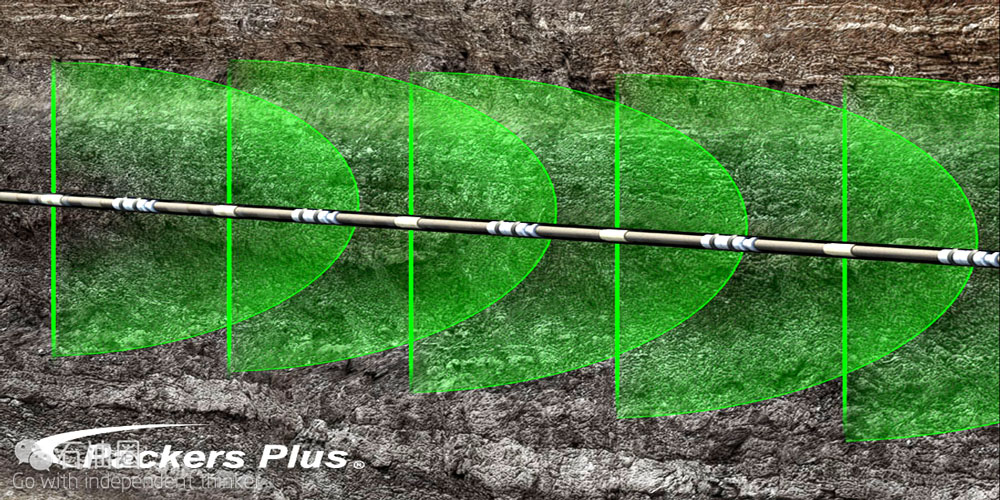

The Packers Plus StackFRAC® HD multi-stage completion systems are designed for open and cased hole stimulation in unconventional tight oil and gas formations. This innovative, field-proven system allows for exact placement of stimulation treatments in one continuous pumping operation. Once the stimulation operation is complete, the well can be immediately flowed back and put on production. StackFRAC HD systems provide operators with an efficient and cost-effective method to complete their wells.

Because the Packers Plus StackFRAC HD system is modular with regard to tool placement, it can be combined with other Packers Plus tools and systems, enabling customized design for targeted delivery of the stimulation program.

Features and Benefits

1.Mechanical stage isolation with field-proven RockSEAL® H2 packers

2.Continuous rigless pumping operation reduces completion time and cost

3.Access to natural fractures in open hole applications

4.Full coverage in extended reach horizontal wells

5.Custom stimulation of the entire wellbore

6.Immediate flowback after stimulation

7.Improved production results

8.Compatible with other Packers Plus tools and systems

Applications

1.Open and cased hole horizontal and vertical wells

2.Multi-stage stimulation

3.Pre- and post-stimulation production testing

4.Tight oil and gas formations

5.Critical sour and HPHT environments

6.Extended reach horizontal wells

7.Multi-laterals

See what the StackFRAC HD system is made of

RockSEAL H2 Packer

The RockSEAL H2 packer is a hydraulically set, mechanical packer. The dual-element design, along with premium seal technology, ensures reliable high-pressure zonal isolation during stimulation and throughout the life of the well. The RockSEAL H2 packer offers ease of installation through its short length, minimum outside diameter and anti-preset features. Hydraulic activation allows for precise control over the setting operation, resulting in time and cost efficiencies.

RockSEAL IIS Packer

The RockSEAL llS is a single-element, double-grip, hydraulically set retrievable open hole packer. It maintains the proven mechanical and element system of the dual-element packer along with an added anchoring capability. The anchoring slip design allows the packer to anchor the StackFRAC HD system at the toe of the well, wellbore junctions or other areas that require extra stability. This packer is typically run in conjunction with the RockSEAL H2 packer for added sealing capability, but can be used on its own as required.

FracPORT H2 Sleeve

The FracPORT™ H2 sleeve is a ball-actuated, hydraulically activated injection/production port. This sleeve is run between two RockSEAL H2 packers to allow specific zones of the wellbore to be isolated and selectively stimulated. By providing a flow area greater than the liner, the FracPORT H2 sleeve provides unrestricted flow for stimulation treatments. The FracPORT H2 sleeve is also available in a Drillable Closeable (DC) version that can be closed or re-opened for future operations. This allows for effective water or gas shutoff, flow control, re-fracturing and production testing.

Hydraulic FracPORT Sleeve

The Hydraulic FracPORT sleeve is a hydraulically activated injection/production port used for the first stage of all Packers Plus stimulation system applications. This sleeve opens at a specific pressure allowing communication between the tool string and the annulus. The unique configuration of the Hydraulic FracPORT sleeve ensures full opening for effective stimulation of the first stage. The Hydraulic FracPORT sleeve is also available in a DC version that can be closed and re-opened for future operations.

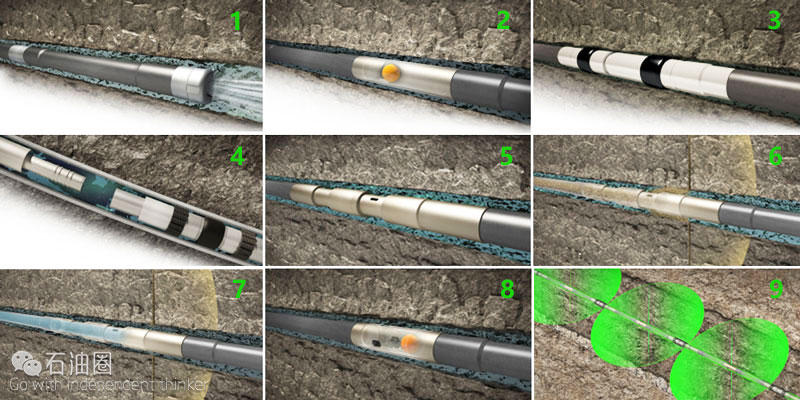

See how the StackFRAC HD system works

1.The StackFRAC HD system is installed with a rig by spacing out tools on production liner. When the desired total depth is reached, the wellbore can be circulated over to completion fluid.

2.A ball is pumped from surface to the toe of the system to close off flow with the annulus allowing hydraulic pressure to build inside the system.

3.This pressure sets the system by hydraulically activating the packer and anchor tools. This anchors the system in the casing and open hole, and creates individually isolated stages along the wellbore.

4.Once the system has been set, the running string is removed and the fracture string is installed. The rig is removed and stimulation equipment is brought on location.

5.Stimulation of the first stage is initiated at the toe of the wellbore using a Hydraulic FracPORT sleeve, which is opened by further increasing hydraulic pressure.

6.Fluid pressure is further increased causing a fracture to form in the rock. Proppant is then pumped as a slurry behind the fluid to fill the fracture.

7.A pad of fluid is pumped to flush the system of proppant above the stimulated stage. The amount of fluid is precisely calculated to prevent overdisplacement of the proppant, ensuring connectivity to the wellbore.

8.Stimulation of the second stage is initiated by pumping a slightly larger ball right after the pad of fluid. This ball lands in a FracPORT H2 sleeve and hydraulic pressure is increased causing the sleeve to open.

9.This process is repeated in a single, continuous pumping operation. The well can be immediately flowed back and production brought on line. If desired, the system can be milled out.

CASE STUDY

StackFRAC HD hybrid system stimulates 50 stages in less than 2 days

Background

The Niobrara formation is located in the Rocky Mountain region across Colorado and Wyoming. Containing both source shale and a carbonate-rich chalk reservoir, the Niobrara is known for its high natural fracture density and operators in the area tend to target zones with this characteristic.

Challenge

An operator working in Weld County, Colorado, was interested in increasing lateral length while maximizing stage density on wells in the Niobrara formation. At the time, the operator was averaging 20 stages per well at a lateral length of 4,328 ft. This operator wanted to continue using open hole, multi-stage completion systems in the extended reach laterals to provide specific zonal isolation while exploiting the natural fractures within the formation.

Solution

Packers Plus designed a high stage count completion strategy for the operator that would take advantage of the operational efficiency of ball-drop completion technology and provide an unlimited stage count. Considering the operator’s completion design rates, a 50- and 51-stage system were designed and installed that implemented the StackFRAC® HD system at the toe of the well until a full bore inner-diameter sleeve was achieved. In the heel of the well, RockSEAL® H2 packers were used in conjunction with an open hole, plug-and-perf completion method.

Results

Both wells were successfully stimulated within two weeks following the installation. All of the stages were stimulated as designed and each well was completed in less than 2 days, saving the operator significant operational time and cost when compared to a 50-stage well completed using solely plug-and-perf methods.

As all Packers Plus systems are modular, the combination of a StackFRAC HD system and a plug-and-perf system can be run into the wellbore together, enabling the customized design of a targeted completion program. The combination of these two methods increases direct reservoir contact and can maximize stage density by decreasing stage spacing. Packers Plus is the innovator of multi-stage completion systems and is an industry leader in designing and manufacturing technology-based solutions for a variety of completion solutions.

石油圈

石油圈