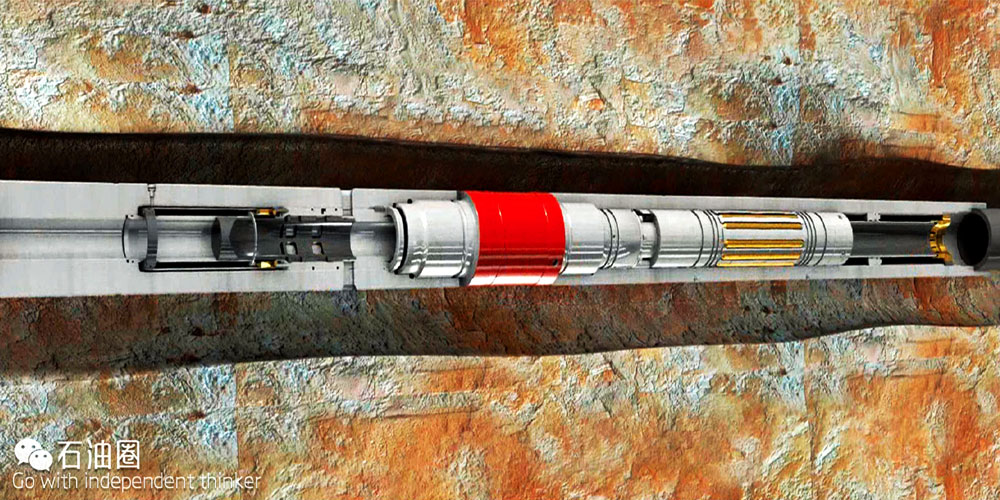

Weatherford-JetStream® RFID Circulation Sub

As wellbores have increased in complexity, conventional drilling reamers and circulation subs have declined in efficiency. These tools also increase rig costs because they require multiple trips for mechanical or hydraulic activation.

Innovative application of active and passive radio frequency identification (RFID) technologies provides a game-changing range of options for downhole control and surface asset management. Active RFID provides new capabilities to enlarge holes, to circulate fluids for hole cleanup, and to reduce rathole length. Passive RFID provides a robust means to precisely track drillpipe for enhanced safety and efficiency.

The Jetstream RFID drilling circulation sub achieves higher flow rates and better hole cleanup than conventional ball-drop tools.

Its RFID-actuated circulating valve can be opened or closed an unlimited number of times by dropping an RFID tag from the surface and circulating it through the sub. This capability also enables the use of multiple tools in the drillstring and eliminates tripping to greatly improve efficiency and uptime. It also eliminates the need for flow-restricting ball seats to provide full through-bore access for wireline operations.

RFID-enabled drilling reamers and circulation subs provide multiple, on-demand activations and deactivations, help preserve mud properties to improve circulation and drilling time, allow wireline access to tools below the reamer, and enable multiple standby tools to be run in the same drillstring. RFID technology can mean the difference between a cost-effective operation and an over-budget one, especially when rig rates and spread costs are high.

Unlock the potential of your drilling operations

The key to unlocking the full potential of your drilling operations has two components: the ability to adjust operations for unanticipated challenges, and the ability to complete the job in as few trips as possible. With three positions, multiple applications, and dynamic activation options, the JetStream RFID circulation sub gives you the power to achieve maximum drilling efficiency and operational flexibility.

Open the door to:

• Increased annular velocity;

• Clean wellbores and blowout preventer (BOP) stacks;

• Lower nonproductive time (NPT) ;

• Efficient spotting of lost-circulation material (LCM) and kill-weight fluids.

Get a handle on efficiency

Many circulation subs can clean wellbores, spot remediation fluids, and jet BOPs—but not all three in one trip. The JetStream sub is different. Because there is no limit to the number of actuations, you can use a single JetStream sub as many times as needed to execute multiple operations without tripping out. The ability to run multiple JetStream subs in tandem—with subs at different, strategic positions along the drillstring—gives you additional functionality and flexibility.

Keep all options open while downhole

A single deployment of the JetStream sub enables several different applications:

During drilling: boosts annular velocity for more effective wellbore cleanup

For remediation: precisely spots LCM and kill-weight fluids to restore mud flow

After drilling: produces turbulent flow downhole for hole cleaning; jets subsea BOPs and wellheads.

How downhole RFID technology enhances operational flexibility

When seeking to boost the flow of fluids from one area to another, one of the simplest solutions is to remove any obstacles from the path. The JetStream sub accomplishes exactly that by eliminating bulky mechanical actuators and their associated risks, which enables full throughbore flow and maximizes the total flow area.

Unlike most circulation subs on the market, the JetStream sub is controlled using RFID—short for radio-frequency identification—technology. Our field specialists program multiple RFID tags at the surface, which enables on-demand deployment of the tags throughout the operation. When the driller needs to actuate the sub, an RFID tag is dropped from the surface and communicates commands to the sub as it flows past the tool. Upon receipt of the RFID signal, a hydraulic pump driven by a batterypowered electric motor moves a sleeve into one of three pre-configured positions: open, closed, or our unique split-flow position.

RFID technology offers several advantages over traditional actuation devices. In the absence of bulky balls, seats, darts, and pins, the inside diameter (ID) remains at full bore throughout the drilling process. The result is higher annular velocity and turbulent flow.

The JetStream sub also saves time by enabling selective, unlimited activation of a series of subs without the need to pull out of hole. Finally, because the JetStream sub does not rely on downhole hydraulics for actuation, the tool is effective in a variety of applications, including low-flow and underbalanced drilling operations.

In addition to the first RFID-actuated circulating valve, the JetStream sub features a number of other advanced technologies.

Onboard memory

The circulating valve logs all downhole events, including time, drillpipe pressure, hydraulic pressure inside the sub, temperature, and battery capacity. An i-Rabbit® close-proximity wireless communication device enables data to be quickly retrieved and displayed on a vertical strip chart.

Large ID and port flow area

At 6.5 in.2 (4,185.4 mm2 )*, the port flow area of the JetStream sub is among the largest in the industry. The sub also features a large ID that is not restricted by bulky balls or seats and remains at full bore throughout each operation. The fullbore ID boosts flow rates and enables operators to access tools in the lower bottomhole assembly (BHA).

Split-flow position

The JetStream sub can be configured with an option to open the ports and the diverter simultaneously to clean out cuttings while drilling. The split-flow position is especially useful in drilling-withliner and low-flow operations.

Adjustable nozzles

Numerous nozzle configurations enable you to define how the flow is split between the annulus and the BHA. By controlling the amount of fluid that is diverted, you can adjust the total flow area and boost annular velocity.

Backup system

A pressure cycling sequence is available for backup communication.

Case study

Caspian Sea-1.5 DAYS AND $350,000 SAVED

Weatherford deployed the JetStream sub above other BHA components that included a conventional underreamer. Because the JetStream sub has a large ID and no ball seats, the driller was able to access and use tools on the lower end of the BHA to perform several operations during the same trip.

By minimizing the number of trips required to complete drilling, the JetStream sub saved the operator 1.5 days of offshore rig time valued at approximately US $350,000. The sub also helped to achieve high flow rates, high annular velocity, and turbulent flow, which contributed to better hole clean-out and improved wellbore integrity.

石油圈

石油圈