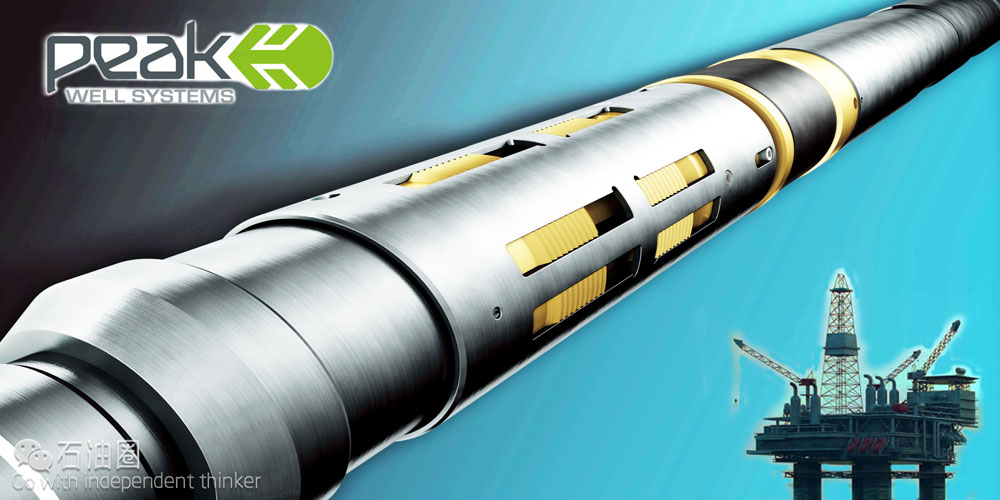

Peak Well Systems (“Peak”), a leading specialist in the design and development of advanced downhole tools for well intervention, is pleased to announce the launch of the SIMULTRA Retrievable Bridge Plug suitable for gas wells and other extremely challenging applications. The new SIMULTRA range incorporates MetaPlex technology, a unique hybrid metal-elastomer seal that delivers both exceptional performance and improved recovery reliability.

SIMULTRA is part of Peak’s new generation of flow control products – a range of ISO-14310 V0 certified downhole sealing systems proven to meet the extremes of high performance, high pressure, high temperature and gas wells.

Without having to rely purely on elastomer elements, SIMULTRA Retrievable Bridge Plugs have the smallest running diameter in their class, offer a larger internal flow path, provide the highest available seal integrity, and retract to smaller than their original diameter, thereby ensuring reliable deployment and recovery every time.

Set and retrieved using Peak’s modular, non-explosive PowerTool, deployment is possible in vertical and horizontal wells using all conventional conveyance methods providing unrivalled operational flexibility and confidence.

Peak successfully completed V0 gas tests at 135degC and 7.5kpsi on its 4-1/2” SIMULTRA plug in August. Tests were undertaken at Peak’s new state-of-the-art gas pressure testing facility located in Aberdeen and were witnessed and validated by third-party certifying authority, Det Norske Veritas.

Further testing in October has now extended that range to 175degC and provided the option of a fully NACE seal solution for sour or high chloride situations.

SIMULTRA Retrievable Bridge Plugs are currently available for industry standard tubulars in 4-1/2” and 5-1/2” casing sizes with a 7” option expected to complete testing in Q1 2016.

Nigel Avern, Chief Executive Officer at Peak Well Systems, said: “Peak is committed to developing new products that will increase the operating window and improve both the life and the productivity of our customers’ wells as they face ever more challenging high pressure/high temperature conditions and increased gas production that limit the capabilities of existing technologies.”

Peak will be showcasing the SIMULTRA plug and MetaPlex seal technology at the Abu Dhabi International Petroleum Exhibition and Conference in Abu Dhabi (9-12 November 2015) and the Intervention & Coiled Tubing Association’s European Well Intervention Conference in Aberdeen (11-12 November 2015).

The design simplicity of Peak Plug Systems offers cost effective deployment and flexibility in remote locations. They have an advanced mechanical setting mechanism, eliminating the need for complex and dangerous setting tools and making them very safe and reliable to use. Furthermore, like the deployment systems, they can be easily redressed in the field by personnel with a limited understanding of English.

Peak Plug Systems are universally compliant with all deployment methods such as slickline, wireline, coiled tubing, drillpipe and tractor.

•The adaptability of Peak’s Plug Systems enables use in a number of different applications:

•Collision barrier during drilling operations

•Wellhead isolation

•Zonal isolation for water shut-off

•Zonal isolation to prevent cross flow / co-mingling

•Downhole choke – choking back unwanted / excessive gas production

•Packer setting and tubing tests during completions / workovers

•Tubing integrity testing

•Abandonment projects

Ultimate Sealing Performance, For the most challenging downhole conditions

A new era of energy production demands a new generation of downhole plugs – tools proven to meet the extremes of high performance, HPHT and gas wells.

SIM from Peak Well Systems represents the ultimate in reliability and retrievability, embodying the highest performance specification for the toughest applications.

Part of our SIM range of superior, nipple-less flow control devices, SIMULTRA Retrievable Bridge Plugs use the same simple design principles, high quality manufacture and versatile deployment solutions to optimise them to be

Plugs are available for industry standard tubulars ranging from 4-1⁄2” up to 7”. Set and retrieved using Peak’s modular, non-explosive PowerTool, deployment is possible in vertical and horizontal wells using all conventional conveyance methods.

•Full V0 certification

•Multiple deployment options, inc. slickline, e-line, coil tubing, drill pipe or tractor

•175oC, 7,500psi performance

•Full sour service capability

•Fully field-redressable, minimising NPT Compatible with other SIM System accessories

Groundbreaking Technology, Banishes retrievability issues

The simRetrievable Bridge Plug incorporates the breakthrough hybrid MetaPlex seal within Peak’s trusted plug architecture to create not just a reliable well barrier, but exceptional retrievability

We’ve taken the next leap forward in downhole sealing technology with SIMULTRA creating a unique, hybrid metal-elastomer seal that delivers both exceptional isolation and superior retrieval.

Without having to rely purely on elastomer elements, plugs have the smallest running diameter in their class, provide the highest available seal integrity, and retract to smaller than their original diameter, thereby ensuring reliable deployment and recovery every time.

•Unrivalled running clearance

•110% retraction assurance

•Eliminates elastomer permanent set

•Eliminates elastomer decompression

•Full metal contact

The modular PowerTool is designed for rapid tool deployment and turnaround on all conveyance systems. For slickline operations, the downhole intelligent Decision Module provides enhanced setting assurance through the use of measurements of time, temperature, pressure and tool movement to identify the correct setting depth.

About Peak Well Systems

Peak Well Systems is a leading specialist in the design and manufacture of advanced downhole tools for well intervention. We provide both operators and service companies around the world with an extensive range of innovative downhole products, expert field deployment and aftermarket support. Our aim is to reduce well operating costs and improve well performance for our customers.

Our product portfolio comprises of Flow Control systems, which are fast becoming the products of choice around the world, and Premium Well Intervention tools for remedial well maintenance.

石油圈

石油圈