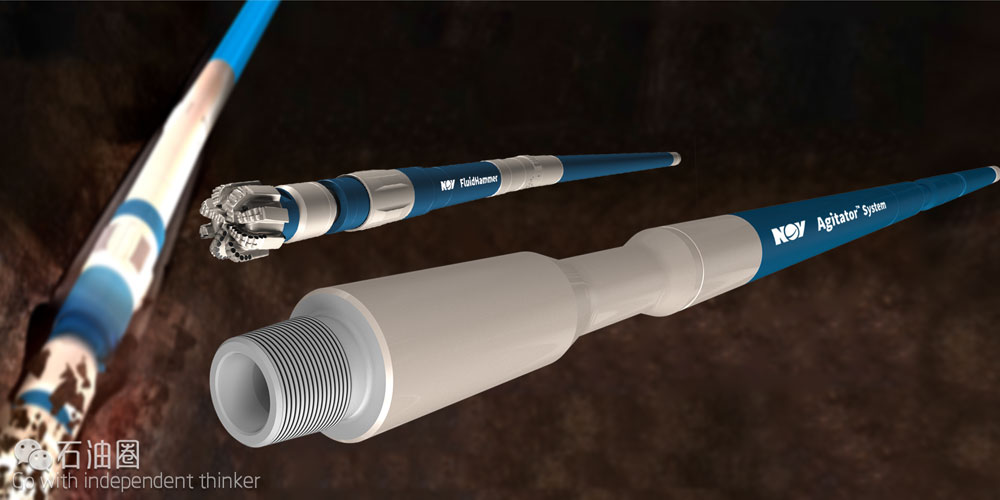

The Agitator™ system increases ROP, improves weight transfer, and reduces stick-slip by reducing downhole friction in directional drilling applications. Its axial oscillations also provide significant benefits for wellbore intervention and fishing applications.

Combining the Agitator™ tool and a shock tool, the Agitator system reduces friction and improves weight transfer to the bit by introducing an axial oscillating motion to keep the drillstring moving. The result is higher ROP, enhanced toolface control, and reduced stick-slip in all modes of drilling, whether sliding or rotating. The Agitator system has shown benefits in all well profiles and is compatible with all downhole motors, rotary steerable systems, and MWD/LWD systems with pre-job planning.

The power section in our Agitator system is used in a completely different manner than a power section in a mud motor, which can be susceptible to chunking issues. Since the rotor in the Agitator tool spins freely with virtually no torque load, the elastomer experiences very little loading and has proven to be 99.9% reliable.

In fishing applications, the high-frequency axial oscillations of our Agitator system can help to free stuck objects improving the efficiency of standard fishing tools in the BHA.

1.Drilling

Developed by Andergauge in the late 1990s, the Agitator™ system is used on every continent where drilling occurs. This patented device is simple, reliable, and extremely effective in a wide variety of applications. We maintain a fleet of over 1,000 tools globally and endeavors to make the Agitator system readily available to our customers for any drilling, coiled tubing, or intervention application.

The Agitatorsystem is the industry leader in downhole friction reduction tools, and it is run routinely in directional and horizontal drilling applications due to the significant performance improvement it provides. These solutions have been proven by operators around the world in over 50,000 runs.

Our Drilling Solutions Engineers (DSEs), located locally in our service districts around the globe, assist customers with customized setup and placement of the tool. With sizes ranging from 1 11/16” to 9 5/8” outside diameter (OD), we can supply the Agitatorsystem for virtually any downhole application.

The Agitatorsystem is compatible with all MWD systems and provides a viable means of extending long reach targets while improving ROP, reducing bit wear and minimizing the chance of differential sticking.

MWD/LWD Compatibility

•Specific MWD setup criteria – see Section 3c

•Reduces lateral and torsional vibration

•Run above or below the MWD

•No impact force to the bit or tubulars

Bit Friendly

•Can be used with roller cone or fixed cutter bits

•No impact forces to damage the teeth or bearings

•Extends PDC life through controlled weight transfer,eliminates spudding

Directional and Vertical Well Enhancement

•Prevents weight stacking and allows excellent toolface control

•Provides a means of sliding at increased ROP and lowers the required weight on bit

•Allows weight transfer with less drill pipe compression

•Works with rotary steerable systems (RSS) to prevent stick/slip

Features and Benefits of the AgitatorSystem

•Gentle oscilation of the BHA reduces friction and dramatically improves weight transfer

•No impact force to downhole tools

•Prevents weight stacking and allows excellent tool face control

•Multiple placement possibilities

•Self-operating tool

•Increased sliding ROP

•Field proven to work with RSS

•Compatible with all MWD systems with pre-job planning

•Decreased lateral and torsional vibration

•Extended bit life

•High efficiency and reliability

•Saves time and drilling costs

The Agitatorsystem allows steerable motors to expand the boundaries of extended reach drilling and enhances their efficiency in less complex applications. The Agitatorsystem increases the drilling efficiency of any drilling system where friction is an issue.

2.Intervention and Coiled Tubing

The Agitator™ tool has become the industry standard in coiled tubing applications for milling bridge plugs and packers in completion applications. The significant reduction in friction along the coil allows milling in extended reach applications.

The Agitatorsystem has been used to convey memory logs, perforating guns, mill composite plugs, and to slide stuck tubing sleeves at the end of tortuous completion strings. It has also proven beneficial in running liners and in the retrieval of stuck liner/casing strings.

3. Fishing

The Agitator ™ fishing system provides axial oscillation, reducing friction and aiding in the retrieval of stuck fish. The system potentially eliminates the need for additional cementing and sidetracking jobs.

With an increased success rate in the retrieval of stuck tubing, casing, and BHAs in a variety of challenging applications, the Agitator fishing system can help you eliminate days wasted jarring and idle fishing. By maximizing your fishing success rates, the Agitatorfishing system reduces additional fishing operation costs.

In fishing applications, the Agitatorsystem has proven to be very effective in helping retrieve stuck BHAs, packers, washpipe assemblies, sand screens, and just about anything else that may become stuck downhole, particularly when differentially or sand stuck.

Conventional fishing BHAs and fishing techniques to recover lost BHAs or other objects stuck downhole are generally limited to either applying overpull or jarring to free the object.

When added to a fishing BHA, the Agitatorfishing system provides axial oscillating motion, which can greatly improve the likelihood of retrieving the stuck object.

This functionality is complementary to the fishing jar, and the Agitatorfishing system can be used either with our without jarring. Whereas jarring generates a large single impact force, the Agitatorfishing system generates a smaller force at a much higher frequency. By inducing an oscillating motion in the stuck object, it loosens contact with the formation and helps to wiggle it free.

Features/Benefits

•Achieves results in previously failed fishing attempts

•Significantly increases rate of success for retrieval of stuck BHAs and pipe

•Eliminates expensive cementing and sidetracking operations

•Strength and frequency of the oscillations is customizable to your operation

•Reduces non-productive rig time and time spent fishing

•Reduces lost-in-hole costs

•Compatible with standard fishing tools

4.Agitator™ PLUS System

The Agitator™ PLUS system increases ROP, improves weight transfer, and reduces stick-slip by reducing downhole friction in directional drilling applications with a lower system pressure drop.

The AgitatorPLUS system combines our Agitator tool with a specially-designed low-pressure shock tool to reduce friction and keep the drillstring mobing by introducing an axial oscillating motion. Optimized to function as a unified system, we’ve configured the AgitatorPLUS system with an overall pressure drop of 300–400 psi. This allows you to maintain higher flow rates, run the AgitatorPLUS system on rigs with limited pump pressure capacity, and even to run two Agitator systems simultaneously in your drill string.

The AgitatorPLUS system is compatible with all downhole motors, rotary steerable systems, and MWD/LWD systems with pre-job planning.

Advantages

•300 – 400 psi pressure drop range, compared to 500 – 600 psi for standard Agitatorsystem

•Reduced size of pressure pulses traveling up or down the drill string

Value To The Customer

•Maintain higher flow rates in long laterals

•Ability to run the Agitatorsystem on rigs with pump pressure limitations

•Reduced pressure pulse amplitude and signal reflection, minimizing effects on the MWD signal

•Ability to run two AgitatorPLUS systems in tortuous well profiles or extended reach laterals for added friction reduction benefits

5.Other Application

•Stuck BHAs (differential/mechanical)

•Casing retrieval

•ESP retrieval

•Pulling sand screens

•Pulling packers

石油圈

石油圈