The SmartBall® platform offers a variety of solutions for managing infrastructure, including leak and air pocket detection for water and wastewater pipelines, verification of containment surveys for oil and gas pipelines, and pipe wall assessment for water and wastewater pipelines.

About SmartBall®

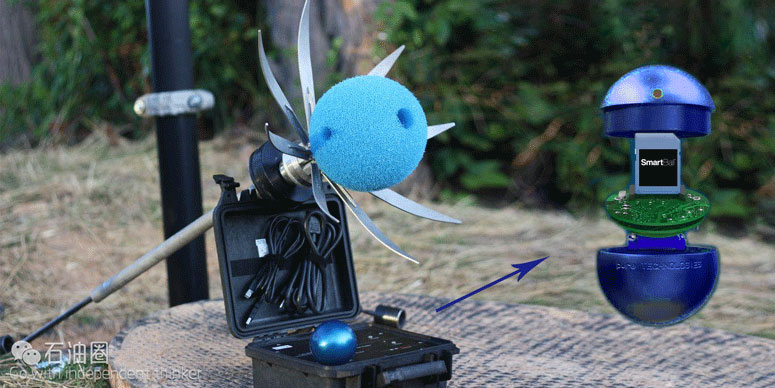

SmartBall® is an acoustic-based technology that detects anomalous acoustic activity associated with leaks or pockets of trapped gas in pressurized pipes. The SmartBall is composed of an aluminum alloy core that contains a power source, electronic components and instrumentation (including an acoustic sensor, tri-axial accelerometer, triaxial magnetometer, GPS synchronized ultrasonic transmitter, and temperature sensor). The aluminum core is encapsulated inside a protective outer foam shell, which allows the device to be propelled through the pipeline by creating a larger surface area for the water flow to make contact with. The outer foam shell also helps reduce some low frequency ambient noise that is typically present in the pipeline. The SmartBall assembly is deployed into the flow of a pipeline, traverses the pipeline, and is captured at a point downstream.

Advantages of SmartBall®

1) Medium and Large Diameter Pipe: SmartBall® can be used to detect leaks on medium and large diameter pipes in the range of (>12 inches and over 96 inch diameter) have been successfully inspected by SmartBall®.

2) Pipe Material: SmartBall®’s leak detection ability is not affected by pipe material.

3) Sensitivity: The sensitivity of all leak detection technologies is a function of several variables and as a result, no resolute thresholds can be established.

4) Length of Survey: SmartBall® has the ability to record acoustic data for over 12 hours. Depending on flow rates, the tool can inspect long lengths of pipe during a single deployment.

SmartBall® Leak Detection

The SmartBall® leak detection platform is a free-swimming tool that can accurately identify leaks and air pockets in water and wastewater pipelines. It is capable of locating very small leaks typically within 6 feet (1.8 meters) of their actual location.

The tool can complete long surveys in a single deployment without disruption to regular pipelineservice. It is equipped with a highly sensitive acoustic sensor that is able to locate pinhole-sized leaks.

During an inspection, the tool is inserted into a pipeline and travels with the product flow for up to 17 hours while collecting information about leaks and air pockets. It requires only two access points, one for insertion and one for extraction, and is tracked throughout the inspection at predetermined fixed locations on the pipeline.

Inspection Benefits

Easy to deploy through existing pipeline features.

No disruption to regular pipeline service.

Long inspection capabilities from a single deployment.

Highly sensitive acoustic sensor that can locate very small leaks.

SmartBall® Leak Detection for Oil & Gas Pipelines

The SmartBall® inspection tool is an innovative verification of containment technology for oil, gas and petroleum products pipelines.

For pipelines 4 inches (100 millimeters) and larger in diameter, SmartBall offers unparalleled sensitivity and accurate location capability for verification of containment surveys. It is easy to deploy and can be used to complement existing pipeline integrity programs or as an integrity check on non-piggable lines.

SmartBall differs from conventional inspection pigs in that it is not a full-diameter instrument. It rolls silently through the pipeline and the absence of mechanical noise allows unsurpassed acoustic sensitivity. The device can detect small product losses as low as 0.03 gallons per minute (0.11 liters/minute), which is order of magnitude more sensitive than CPM-based systems.

As pipe diameter increases, the SmartBall tool retains its sensitivity while CPM systems become less accurate. Productloss location accuracy is typically within 2 meters, depending on availability of tracking locations. The device can be deployed and retrieved using existing pigging facilities. In non-piggable lines, the device can be launched using off-the-shelf fittings. Travel time can last up to 20 hours for 4-inch (100 millimeter) lines and over 400 hours for larger lines.

Oil and Gas pipelines can also benefit from SmartBall PWA which identifies stress in the pipe wall based on a changing magnetic signature. PWA identifies areas of possible concern for further investigation as part of a Pipeline Management Integrity Program.

Applications:

Routine verification of containment surveys

Emergency product loss locating, minimizing losses and cleanup costs

Validation of alarms generated by CPM systems (with accurate locations in the PWAcase of product loss)

Acceptance testing of new pipelines

Product theft detection

SmartBall® Pipe Wall Assessment

The SmartBall® Pipe Wall Assessment (PWA) tool is a free-swimming technology used to identify stress in the pipe wall of pressurized metallic pipelines.

The SmartBall PWA tool can complete long assessment surveys in a single deployment without disruption to regular pipeline service. The tool is inserted into a live pipeline and travels with theproduct flow for up to twelve hours while collecting pipe wall data and listening for leaks at the same time. It requires only two access points: one for insertion and one for extraction. The SmartBall PWA tool is tracked throughout the inspection as it passes available access points on the pipeline.

SmartBall PWA Capabilities

Identify each pipe joint and most appurtenances, valves etc.

Identify material changes and repairs.

Identify damaged pipes.

Estimate the damage levels of those pipes and indicate the position along each pipe where damage is located.

Estimate when damage is at the crown of the pipe.

Precisely indicate the position of each damaged pipe relative to known points.

About Pure Technologies

Pure Technologies is a world leader in the development and application of innovative technologies for inspection, monitoring and management of critical infrastructure. Pure’s expertise and technologies are being used around the world to help utility operators mitigate the impact of deterioration and maximize capital budgets for rehabilitation and replacement programs.

石油圈

石油圈