当前,海上生产井的封堵弃置作业(以下简称P&A)高额成本着实成为运营公司与国家主管部门的沉重负担。仅在挪威大陆架区域,预计接下来40年的相应的P&A作业费用高达1080亿美元。基于此,DNV GL集团将推出一种基于风险评估的操作规程(工业标准,以下简称RP)来取代现行操作规范。

该公司表示,如果P&A作业能够与优化的项目执行流程以及新技术相结合,则作业费用可降低30%~50%。RP内容的概述框架为个性化的单井弃置作业设计提供了可能性,并与行业内现行略显古板的P&A操作规范形成了鲜明对比。

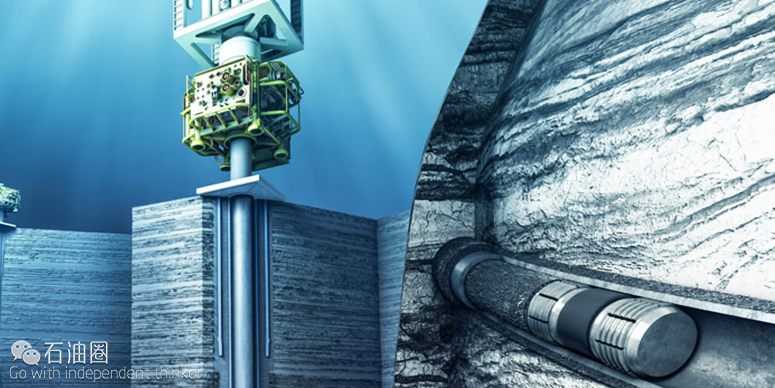

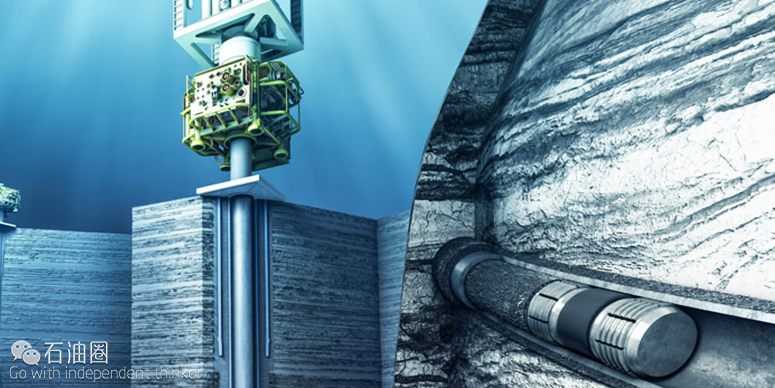

在今年5月2日休斯顿召开的国际海洋石油技术博览会上,DNV GL集团发布了RP技术文件及相关介绍。当油气藏储层资源枯竭或者不再有利可图时,运营商便会根据单井的产出情况实施弃井措施。政府主管部门要求运营商以安全、环保性作业方式建立永久性屏障,防止碳氢化合物发生溢流。

Per Jahre-Nilsen,DNV GL集团石油与天然气业务拓展经理。他表示:“P&A作业费用颇为高昂。根据现行操作规程,全球范围内仍然需要数量众多的钻机全天候实施作业,作业方式亟待革新!我们认为现在即是变革的时间节点,协助监管部门和油气行业建立一个生产井P&A操作的新型规范。”

“通过实施新规范,可有效保障潜在风险较大单井得到足够的重视,潜在风险较小的井避免过多的钻机工作时间,这会有效提高资源配置效率并节约成本。我们预估通过实施新规范,仅在挪威大陆架区域的P&A作业较之前就可节约320亿美元成本,若在全球范围内推广应用的话,成本节约效果将更加显著。”

据报道,DNV GL公司发布的DNV GL-RP-E103《海上生产井基于风险的弃置作业操作规范》文件是基于公司在2011年的实际工程案例编撰的。这次建立的新方法涵盖所有关键阶段的系统操作体系,包括井眼封堵屏障失效模式评价、储层最大产能分析、生态体系构成及价值评估、碳氢化合物弥散建模与影响分析。根据RP制定的目标井弃置设计,可有效保障作业稳健性、环保性且可节约成本。

Elisabeth Tørstad,DNV GL 集团石油与天然气业务CEO。他表示:“DNV GL集团公司致力于帮助油气行业了解并管控各类作业风险。基于风险的监管方法广泛应用于其他海上工程领域,是最为高效的安全作业保障方法,并且能够确保长期性的环境保护。由彼及此,现在是时候将这种机制引入到P&A作业中来了。”

DNV GL 集团相关责任人表示,现行操作规范即是P&A作业领域引入基于风险的监管方法的主要阻碍,虽然现行的操作规范可满足各种规程要求,也能完成作业,但代表的却是保守过时的技术,效率较低。此外,每个国家的操作规范也不尽相同,这也会在一定程度上阻碍RP的推广。

根据DNV GL 公司报告,新型RP应用了成熟的基于风险方法理论(环境与安全风险是该理论的关键因素)。在新型RP的研讨过程中,DNV GL 公司和众多国际油气运营商联力制定出一份初期的风险评估标准,并通过案例研究反复探究完善。之后,通过与国家监管机构和从业者的多方交流沟通,实现标准与规范的进一步强化、细化。

来自/DNV GL等 译者/姚园 编辑/Lemon

The plugging and abandonment (P&A) of offshore wells represents a significant cost to operating companies and national authorities. On the Norwegian Continental Shelf (NCS) alone, the cost is estimated to be USD108bn (NOK 870bn[1]) over the next 40 years. Now a new DNV GL guideline will introduce a risk-based approach instead of the current prescriptive practice. DNV GL estimates that when combined with optimized project execution and new technology, the P&A cost can be reduced by 30-50%.

DNV GL has issued a new Recommended Practice (RP) on risk-based abandonment of offshore wells which in combination with optimized project execution and new technology could potentially reduce P&A costs by 30–50%.

The framework outlined in the RP provides the possibility for individualized, fit-for purpose well abandonment designs, a contrast to the prescriptive methodology available in the industry today.

DNV GL issued a technical paper and presentation on the RP held at the Offshore Technology Conference (OTC) in Houston on Monday May 2.

Well abandonment is driven by economic decisions, when the production of an oil or gas reservoir ceases or is no longer profitable. Authorities require that well operators perform safe and environmentally friendly operations by establishing a permanent barrier to prevent release of hydrocarbons to the surface.

“The costs related to well P&A are enormous. Using current practices, there will be a global fleet of dozens of full-time drilling rigs needed to perform P&A for generations to come. We believe the time has come to tackle this issue head on by assisting regulators and the industry to establish a new methodology for dealing with the decommissioning of wells. By using this method, hazardous wells will get the attention they deserve, and benign wells will avoid excessive rig-time and expenditure. We’re looking at potential cost savings of more than USD32bn on the NCS alone, and even more globally,” says Per Jahre-Nilsen, business development leader, DNV GL – Oil & Gas.

Reportedly, the DNVGL-RP-E103 ‘Risk based abandonment of offshore wells’ is based on case studies performed by DNV GL in projects dating back to 2011. A thorough process is defined where the key stages in the risk-based methodology are assessing the well barrier failure modes, well flow potential, valued ecosystem and safety components, dispersion modeling and impact analysis. These steps allow for a consistent method to be applied when assessing risk of the offshore well abandonment designs. The RP methodology provides assurance that selected well abandonment designs are robust, environmentally friendly and economically advantageous.

“DNV GL helps the industry to understand and manage the risks of their operations. Risk-based approaches are widely used in all other offshore disciplines, ensuring appropriate long-term environmental protection and also representing the most efficient method to ensure safety. It is time to apply these principles to P&A,” says Elisabeth Tørstad, CEO of DNV GL – Oil & Gas.

The main obstruction to change in this sector has been today’s prescriptive approach to the regulations, which represents a conservative interpretation of past experience and outdated technologies. Practice also differs from country to country. According to DNV GL, the new RP uses well-known and accepted risk-based approach methodology in which both environmental and safety risk aspects are key factors. Through the development of the RP, DNV GL worked with international oil and gas operators to establish an initial set of risk acceptance criteria and cross-checked these using case studies. The criteria and methodology have been further strengthened through dialogue with regulators and industry players, DNV GL said.

未经允许,不得转载本站任何文章:

-

- Demons

-

石油圈认证作者

- 毕业于中国石油大学(北京),化学工程与技术硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系Demons(QQ2582825239;微信15810965891)

石油圈

石油圈