USI推出的新型井口保护装置可大幅提高井筒完整性,保障油气开采顺利进行!

编译 | 惊蛰

在2018年的海洋技术大会初创公司展示部分,Universal Subsea公司总经理Sean Thomas介绍了该公司的Wellhead Defender水下隔离装置,包括其商业应用计划以及申请专利情况。

Thomas说:“我们很高兴被莱斯大学联盟选中参加今年的OTC初创公司综述,这项活动展示了40家有前景的新兴能源科技公司。在油气开发的海底设备中,各种类型的腐蚀与海洋生物的生长,会导致工期延误、产量损失,并增加海上勘探与开发行业的风险。我们与一家大型井口供应商合作多年,亲眼目睹了这些问题。后来,我成为了一家油气巨头公司的技术专家。因此,我下定决心要设计出一款更好的水下防护装置。”

“我们的Wellhead Defender水下隔离装置就应运而生。该产品在本体设计、密封、锁定与注入等方面都拥有众多创新功能,目前正在申请5项美国专利。若与我们的Defender Stasis隔离液配合使用,Wellhead Defender水下隔离装置可有效防止水下井口关键密封以及联锁的腐蚀与海洋生物的生长,从而保持水下井口处于稳定状态。我们的Tree Defender水下隔离装置也可为水下采油树提供上述功能。”

Wellhead Defender水下隔离装置是同类工具中的首款创新型产品。Universal Subsea公司耗费2000多小时,完成了这款一体式耐腐蚀热塑性装置的分析、选择、测试与鉴定。

实际上,相比之下,金属水下保护装置腐蚀的更快。而且,市面上其他水下保护装置通常本体都不带密封,隔离液能够快速泄漏到海洋中。经过24个月的研发历程,Universal Subsea公司解决了现有水下隔离装置的诸多缺陷,建立并验证了一种解决方案,为海上勘探开发公司以及服务商带来了新的信心。水下油气井所处的深海环境极其恶劣,腐蚀、矿物沉积、海洋生物生长,可能会对价值数百万美元的水下设备造成不可磨灭的影响。不过,在改设备的帮助下,这些问题都可迎刃而解。

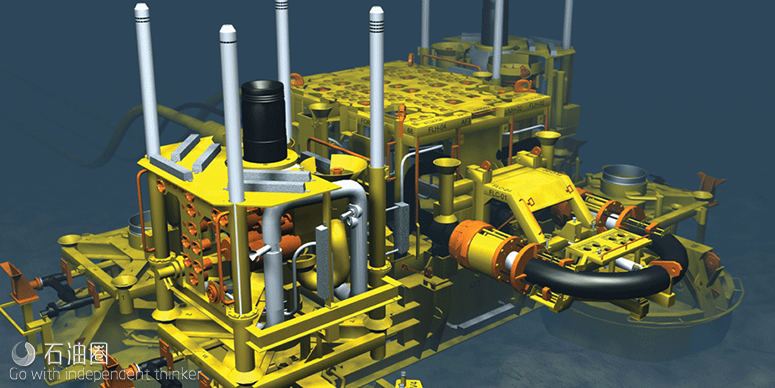

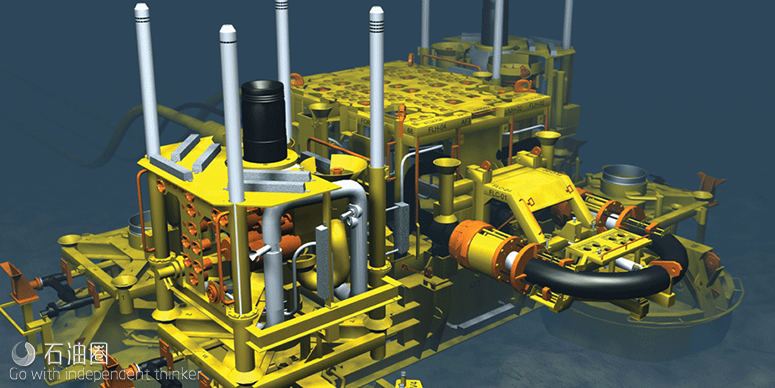

Defender水下隔离装置

Universal Subsea公司先进的热塑性水下隔离装置,可用于水下井口与水下采油树心轴,是首款将心轴和内孔与海底环境完全隔离的保护装置。这种独特的保护装置采用厚壁塑料一体成型技术,为超大尺寸的专有阀体密封提供空间,可靠地密封到心轴之间的大间隙。特殊的阀体密封件可在低压下有效地容纳保护液,同时确保更低的ROV部署与回收的安装施力。重型ROV操作锁定系统确保防护装置牢固地锁定在心轴上,同时降低了井口与防护装置损坏的风险。

USI公司的水下隔离装置与保护液技术使海上油气公司大幅降低了作业成本:

- 消除/减少井口清洁/修复:节省0.4至2.5万美元;

- 消除/减少水下采油树清洁/修复(假设5次干预):节省4至120万美元;

- 降低环形垫圈泄漏的风险:节省8至50万美元;

- 消除保护装置卡住的风险:节省1.4至30万美元;

- 使用轻型修井船而不是钻井平台进行卧式采油树的修井:每次修井节省10至100万美元;

- 消除一些立式采油树常见的水合物问题:每次修井节省1.5至50万美元;

- 将水下采油树的可用寿命延长2至5年:额外收入400万至3000万美元。

USI公司的深水热塑性水下保护装置,可用于新安装的水下井口以及临时弃井的现有井口。通过将水下井口内孔、VX环垫片外部、H-4外部与海洋环境完全隔离,从而阻止所有腐蚀、矿物沉积以及海洋生物生长。适用型号包括外径27in的所有水下井口,还可根据特殊要求提供其他尺寸与型号。其支持多种安装方式,包括ROV,电缆或钻杆等。当前设备的额定深度高达11000英尺(3353米),额定温度最低28华氏度(-2.2摄氏度),也可根据要求,提供更冷的北极额定值。截至目前的测试中,首款低压水下井口保护装置通过了API 6A / 17D PR2压力测试标准,满足应用要求。

For English, Please click here (展开/收缩)

Sean Thomas, P.E., general manager at Universal Subsea Inc., presented the company’s business plan and patent-pending Wellhead Defender subsea isolation cap at the Rice Alliance Startup Roundup at OTC on April 30. The 2018 OTC is being held at the NRG Park from April 30 to May 3 and is the offshore industry’s premier global event.

“We are pleased to have been selected by The Rice Alliance to present at this year’s OTC Startup Roundup, which showcased 40 promising emerging energy technology companies,” said Thomas. “At the seafloor, various types of corrosion and marine growth cause lost time, lost production and increased risk to the offshore E&P industry. I have witnessed these issues first hand, working for years with a major wellhead supplier and then as a Subject Matter Expert with a supermajor operator. I was determined to come up with a better subsea protector cap. Our Wellhead Defender subsea isolation cap is that solution, with numerous innovative features in the body design and the sealing, locking, and injection features, with 5 U.S. patents pending. Used in conjunction with our Defender Stasis isolation fluids, the Wellhead Defender subsea isolation cap effectively prevents corrosion and marine growth on critical sealing and locking features of subsea wellheads, preserving the subsea wellhead in a stasis condition. Our Tree Defender subsea isolation cap provides the same benefits for subsea tree applications.”

The Wellhead Defender subsea isolation cap is the first product of its kind. Universal Subsea spent over 2,000 hrs analyzing, selecting, testing and qualifying the one-piece, corrosion-proof, thermoplastic body.

In contrast, metal subsea protector caps can actually foster corrosion. Furthermore, competing subsea protector caps typically have ineffective body seals, allowing isolation fluid to quickly leak out to the ocean.

Over a 24-month development process, Universal Subsea Inc. solved the many pitfalls of existing subsea isolation cap technology, building and qualifying a solution that will bring new confidence to offshore E&P companies and service providers alike.

The deep ocean setting for subsea oil and gas wells is a hostile environment that can cause extensive damage to multi-million dollar subsea equipment due to corrosion, calcareous deposits, and marine growth.

DEFENDER SUBSEA ISOLATION CAP

Wellhead Defender Subsea Isolation Cap on H-4 Wellhead Test Fixture (multiple patents pending) 2019 Universal Subsea, Inc. All Rights Reserved.

Universal Subsea’s advanced thermoplastic subsea isolation cap for subsea wellheads and subsea tree mandrels is the first protector cap to completely isolate the mandrel and internal bore from the subsea environment. This unique protector cap utilizes thick wall plastic molding technology to provide space for oversized proprietary body seals which reliably seal very large gaps to the mandrel. The special body seals effectively contain preservation fluids at low pressures while ensuring low installation forces for ROV deployment and retrieval. The heavy duty ROV operated locking system ensures that the cap is positively locked to the mandrel while ensuring low risk of damage to the wellhead and the cap.

ECONOMIC BENEFITS

USI’s subsea isolation cap and preservation fluid technologies provide substantial direct cost savings to offshore oil and gas companies:

- Eliminate/reduce wellhead cleaning/remediation: $4,000 – $250,000 savings

- Eliminate/reduce subsea tree cleaning/remediation (assumes 5 interventions): $40,000 – $1,200,000 savings

- Reduced risk of leaking ring gasket: $80,000 – $500,000 savings

- Eliminate risk of stuck protector cap: $14,000 – $3,000,000 savings

- Horizontal tree workover using light intervention vessel instead of drilling rig: $1,000,000 – $10,000,000 savings per intervention

- Eliminate hydrate problems with some common vertical trees: $150,000 – $500,000 savings per intervention

- Extend useable life of subsea production tree by 2 to 5 years: $40,000,000 to $300,000,000 in additional revenue

PRODUCTS AND SERVICES

WELLHEAD DEFENDER SUBSEA ISOLATION CAP

USI’s deepwater thermoplastic subsea protector cap for new subsea wellhead installations and existing temporarily abandoned project wellheads.

- Completely isolates the subsea wellhead bore, VX ring gasket profile, and H-4 profile from the marine environment, thereby halting all corrosion, mineral deposits, and marine growth.

- Models: All subsea wellheads with 27” H-4 profile. Other sizes and models available upon special request.

- Body: High performance marine grade thermoplastic

- Installation: ROV, wireline or drillpipe

- Depth rating: up to 11,000 ft. [3353 m]

- Temperature rating: to 28°F [-2.2°C] minimum (colder Arctic ratings available upon request)

- Testing: First low pressure subsea wellhead protector cap to pass API 6A/17D PR2 pressure test criteria

未经允许,不得转载本站任何文章:

石油圈

石油圈