FracGeo announces the launch of its software module DrillPredictor, a cloud- and subscription-based web service to put completion optimization in the hands of any unconventional reservoir operator. The field-validated technology uses commonly available surface drilling data from any contractor to provide the information needed to adapt any frac treatment to the variable subsurface geologic and geomechanical conditions.

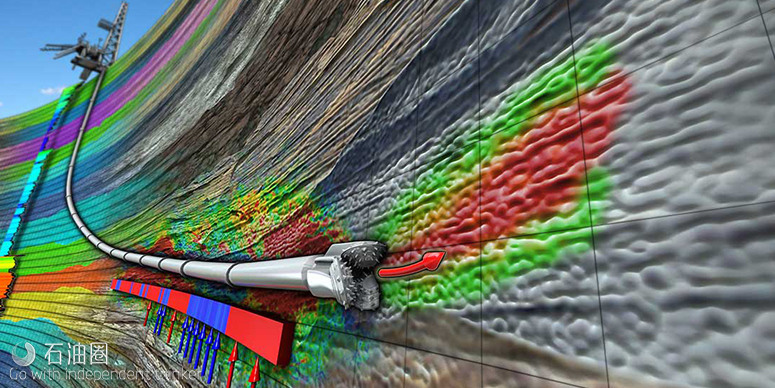

DrillPredictor uses FracGeo’s proprietary Corrected Mechanical Specific Energy (CMSE) which accounts for frictional losses along the wellbore for any type of drilling equipment including RSS and mud motors. FracGeo’s CMSE is used to compute unique products such as pore pressure, stresses, natural fractures, and geomechanical logs along the wellbore. These logs are then used immediately after drilling the well to provide multiple completion optimization strategies that are quantified with an estimated cluster efficiency, followed by the propped fracture geometry and the resulting depletion using FracGeo’s advanced and fast frac design and reservoir simulation technologies.

These estimations are validated with fiber optics, microseismic moment tensor inversions, and production logs. FracGeo clients routinely adjust their treatment parameters with confidence and successfully place all their fracs without increasing downhole risk and insignificant additional cost which is now lowered with the launch of this new cloud-based service.

Peter O’Conor, V.P. of marketing and business development says that “DrillPredictor desktop technology received great feedback from many clients which prompted us to make it available to any operator through this new cloud- and subscription-based application. A major advantage of the technology is its deployment on any well since it only uses surface drilling data thus requiring no additional expense or use of risky downhole equipment.” O’Conor added “additional benefits of the technology now include its low cost with the pay-as-you-go web-based service”.

Ahmed Ouenes, CEO, says, “Improving the completions of unconventional wells has so far been achieved through expensive trial and error field experimentation. DrillPredictor’s new cloud-based pay-as-you-go service provides our clients actionable information to improve their completion at minimal cost, one well at a time”

- Uses commonly available surface drilling data from contractor to provide information needed to adapt any frac treatment to the variable subsurface geologic and geomechanical conditions

- Uses FracGeo’s proprietary CMSE which accounts for frictional losses along the wellbore for any type of drilling equipment including RSS and mud motors

- Benefits include low cost with the pay-as-you-go web-based service

Features:

DrillPredictor™ includes a new technology that uses standard surface drilling data to compute, in real time, the Corrected Mechanical Specific Energy (CMSE) which accounts for frictional losses along the wellbore. FracGeo’s CMSE is used to compute pore pressure, stresses, natural fractures, porosity, and geomechanical logs along the wellbore. Immediately after drilling is completed, DrillPredictor™ provides an optimal completion strategy with adaptive frac stage spacing and cluster design that accounts for the heterogeneous nature of the computed stress and geomechanical properties along the wellbore.

- Corrected Mechanical Specific Energy (CMSE) that accounts for frictional losses in real time

- Estimates in real time, or after drilling is completed, the pore pressure, geomechanical logs, porosity, natural fracture index and the stress brittleness.

- Provides at the end of drilling the optimal frac stage spacing and cluster density based on stress brittleness, Shmin, CMSE or differential stress extracted from GMXPredictor results

- Exports the derived completion design to StimPredictor™ to design the frac treatment

For Engineers and Geoscientists

Learn new skills that will expose you to the latest new science that will improve your understanding of your reservoirs by using field validated technologies. Practice your new skills on real case studies using the first and only 3G integrated software: FracPredictor™.

石油圈

石油圈