Long horizontal laterals open more reservoir to the wellbore for greater conductivity and higher initial production rates…but they also create unique production challenges.

Multiphase fluid flow, which is a challenge for artificial lift systems, is nearly always present in unconventional oil resource plays. And, while horizontal wellbore construction methods do expose more reservoir to the well for greater production, they also exacerbate the unique challenges associated with producing fluids mixed with gas.

During production, as reservoir pressure depletes, natural gas is released from the reservoir and accumulates in the high side of the undulations along the horizontal lateral. When these gas accumulations—or gas slugs—break free and move up the wellbore they create low-flow or no-flow conditions in the artificial lift system. When these conditions occur they:

- Impact system reliability due to cycling and gas lock conditions

- Interrupt production

- Limit ultimate reserve recovery

Eliminate production interuptions

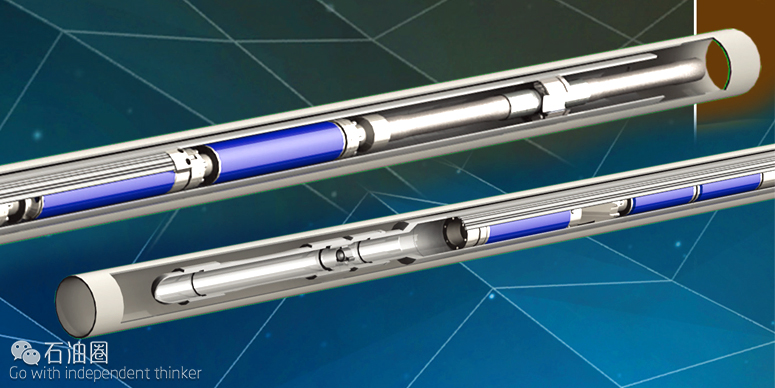

Improve return on investment with a multiphase production solution that encapsulates the entire electrical submersible pumping (ESP) system in a shroud to prevent gas slugs from entering the system. The CENesis PHASETM multiphase encapsulated production solution naturally separates gas from the production stream, which stabilizes production and eliminates reliability issues associated with pump cycling and gas lock conditions. The system design also features a patented recirculation system to ensure adequate motor cooling for even greater reliability.

The shroud provides a reservoir of fluid that allows the ESP system to continue operating when gas slugs displace fluid in the wellbore. The system design creates natural separation when the lighter natural gas continues to rise up the annulus while the heavier liquids enter the shroud to be produced through the ESP system. During gas slug events, the integrated recirculation system keeps continuous flow moving past the ESP motor to prevent overheating

Improve production and reserve recovery

By eliminating the interference of gas slugs, the CENesis PHASE solution stabilizes production rates, improves efficiency, and eliminates down time caused by system cycling and gas locking. Through the life of the well, this continuous production profile more effectively draws down reservoir pressure to release additional hydrocarbons from the reservoir, improving ultimate reserve recovery and return on investment

The system includes the FLEXPumpERTM extended-range pump, which allows operators to produce over a wide flow range and eliminate costly system change outs as production declines. The FLEXPumpER pump has the industry’s widest operating range. And, the wide vane openings standard in the FLEXPump series mixed-flow pump stage designs also help mitigate the impact of natural gas on the system.

Enhance system reliability to reduce OPEX

Incorporating a shroud into the system to separate gas slugs before they can enter the pump dramatically improves ESP reliability since there is no wear and tear on the system due to cycling, gas locking, or pump overheating. The shroud also provides mechanical protection for the motor lead extension during installation in deviated or horizontal wellbores and from downhole pressure changes. For wells with high sand content in the production stream, the CENesis PHASE solution offers abrasion resistant pump technology and sand management devices.

The integrated recirculation system is a key component of the CENesis PHASE design. By constantly diverting fluid past the ESP motor, the recirculation system prevents motor heating, which dramatically improves the reliability of the ESP.

The CENesis PHASE solution has improved the return on investment from hundreds of unconventional oil wells to date

Make artificial lift even more effective to meet your business needs with a full portfolio of gas-management technology and commercial models tailored

Combining a multiphase production system with unmatched gas-handling technology affords even greater operational flexibility in wells with high gas content in the fluid stream. MVPTM gas-handling systems merge a charge pump that compresses gas into solution with a primary pump designed specifically to lift multiphase fluids. AMBITTM ESP monitoring services employing MaxRateTM gas control technology adds the last line of defense, detecting any anomalies caused by gas in the system and adjusting ESP system operating parameters to mitigate the impact

Just as every well has a unique production profile, every operator has a unique set of business drivers, so Baker Hughes provides a range of commercial models to meet each customer’s specific needs. Contact your local Baker Hughes representative to discuss the best technical and commercial solution to your multiphase production challenges.

石油圈

石油圈