The Reel Power OG Patent Pending Loc-Torus II -Remotely Operated Hydraulic Frac Connector is specifically designed to Lower Operating Costs and Improve Safety for the high demands of hydraulic fracturing applications. The remote operation allows connecting the wireline tool string and BOP remotely without personnel entering the high pressure danger zone. This allows the pressure pumping to continue while the tool string is removed and perforating charges are changed out on multi-well pads. The remote operation eliminates the need for a man to go up in a basket lift to disconnect and connect the BOP connection. By continuing with the pressure pumping while changing perforating charges, the time savings is between 20-40 minutes per each stage, paying for itself in just one well. The hydraulic connection provides a sure connection between the Blow Out Preventer and the top of the frac tree. The Loc-Torus II design is based on the company’s Patented Loc-Torus lock over center subsea connector design.

Less connectors are required on the site providing a less expensive and simpler operation. By continuing with the pressure pumping while changing perforating guns, the time savings is between 15-30 minutes per each stage, paying for itself in just one well.

Control features include:

Interlocks to Prevent Unlatch with Bore Pressure

Lock/Unlock Indication with Beacon Lights

Well Bore Pressure Display

Data Logging with Live Communication to Factory

Predictive Maintenance Data

The Loc-Torus II Onsite Control System provides Safe, Simple & Reliable Controls

Operator control system specifically designed for simplicity, includes operatordisplays with keyed and interlocked switches which prevent inadvertent unlatching of the connector with positive bore pressure.

All control components are redundant throughout the system. Making it unlikely that an operator would ever be “down” due to controls.

Connector information can be accessed remotely and sent automatically via text and email making access to the factory faster than ever. Trend analysis for number of connections, pressure and time provide predictive failure analysis data and remote diagnostics.

The Loc-Torus II Connector provides Assured Locking to Wellhead

Failsafe, Spring Locking connectors will stay locked even without actuation pressure. Mechanical Lock Indicator are visible from ground, giving double-assurance you are locked.

Anchored, Plug & Play umbilical bundle assure they will stay in place when snagged and can be quickly changed out, if needed.

Available in 10k & 15k versions

Remote Night Cap & Ball Drop options available

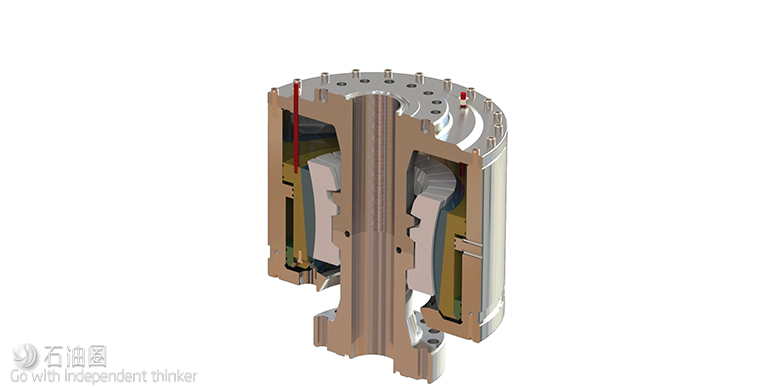

LOC-TORUS SUBSEA WELLHEAD CONNECTOR

The Reel Power OG patented Loc-Torus Hydraulic Connector is a versatile replacement for standard torus style OEM connectors. The Reel Power OG patented “lock over center” design is ideal for multiple use applications where the need for greater reliability and functionality exist, especially in today’s cost conservative marketplace.

Reel Power OG Loc-Torus hydraulic connector was designed with the operator in mind. Not only does it match the versatility of other Torus style connectors in a variety of applications, including subsea tree, Jumper, riser, tubing head, and flowline applications, but adds greater reliability by using our patented “lock over-center” design.

The connector provides a sure connection at the wellhead, the “lock-over-center” design ensures the dogs are uniformly operated into the engaged and disengaged position, similar to the effect of a light switch. The connector was designed to fit standard subsea wellheads with 10K/15K psi pressure rating, standard wellhead hub or mandrel profiles, and for use in multiple aftermarket applications due to the ability to perform multiple lock/unlock actuations. A visual lock indicator rod gives position feedback via an ROV that the connector is locked. Flow zone components are designed for maximum erosion and corrosion life significantly reducing maintenance and replacement costs.

The Radoil Patented Loc-Torus Hydraulic Connector is specifically designed for improved offshore safety. These hydraulic connectors are designed for deep waters and high wellhead pressures. The connector provides a sure connection at the wellhead, the lock-over-center design ensures the dogs are uniformly operated into the engaged and disengaged position, similar to the effect of a light switch. Designed for standard subsea wellheads with 10,000 and 15,000 psi pressure rating. The innovative connector has no tendency to self-release under bore pressure loading or vibration. Visual lock indicator rod gives position feedback via an ROV that the connector is locked. Flow zone components are designed for maximum erosion and corrosion life.

Specifications

No Tendency to Self-Release under Pressure or Vibration

Does Not Require Holding Hydraulic Pressure during operation

Does Not Require Secondary Locking Mechanism

Designed for 10 and 15K psi

Preload Mechanically Set

Can be adopted to older subsea wellhead and mandrel configurations and sizes

Multiple Bore/Pressure combinations available

H2S service capable

Designed for maximum corrosion and erosion protection

Lift eyes for easier handling

Common Uses

Subsea Well Abandonment

BOP Stack to Wellhead

BOP to Riser Connection

Lower Marine Riser Package (LMRP) to Lower BOP Stack

Dry Tree Connector

Completion Trees to Wellhead

石油圈

石油圈