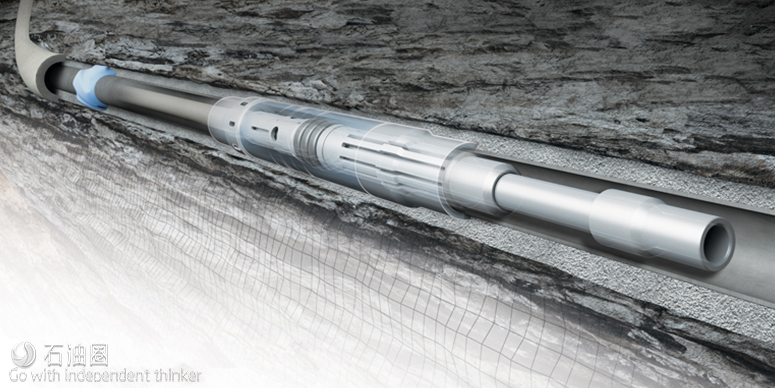

The latest innovation from Packers Plus Energy Services Inc. brings simplicity and reliability to operators for stimulating the first stage of oil and gas wells. The Toe-XT Hydraulic Sleeve is specially designed to enable a maximum casing pressure test before activating the sleeve for stimulation operations.

While these two key operations – pressure test and stimulation – have been combined into one tool, the mechanisms in the Toe-XT for each procedure are completely separate. This provides the operator with no time constraints and operational flexibility in meeting regulatory requirements and completing the well, ensuring capital expenditures are minimized.

During field trials, 4.5-in. and 5.5-in. versions of the Toe-XT Hydraulic Sleeve combined for successful installation and operation in more than 50 wells across North America. Among these installations was a well in the Eaglebine formation of East Texas, where the operator conducted a 30-min. pressure test at 11,450 psi, and then came back a week later to begin stimulation operations.

“Early runs of the Toe-XT Hydraulic Sleeve have been very promising in providing our clients with certainty and operational flexibility,” said Packers Plus President and CEO Ian Bryant. “This innovative tool is complementary with the rest of our multi-stage completion systems, providing an effective way to initiate any completion program.”

The Toe-XT Hydraulic Sleeve is one of a suite of cemented liner options, including a wet shoe tool and rupture disc sub, offering customers flexibility for the toe stage to meet all their technical requirements. The Toe-XT Hydraulic Sleeve is part of the TREX Cemented Product Line, a suite of high-quality technologies designed to increase the efficiency and reduce the operational risk in cemented completions for operators worldwide.

The Toe-XT™ Hydraulic Sleeve is a hydraulically activated injection/production port that is used for the first stage of a completion system. The Toe-XT Hydraulic Sleeve allows the casing string to be pressure tested a single time before opening. Once the test has been performed, the operator can open the Toe-XT Hydraulic Sleeve and commence stimulation operations.

The Toe-XT Hydraulic Sleeve can be used in many applications:

–Pressure testing

–Cemented liner

–Open hole

–Horizontal and vertical wells

–Selective stimulation and production

features and benefits

- Lower operational risk associated with wireline or coiled tubing runs for the first stage

- Verify casing integrity with pressure testing capability

- Reliability with pressure testing independent of stimulation operations

Effective stimulation and millout operations achieved with Packers Plus TREX cemented completion system

Packers Plus worked with an operator in the Marmaton formation to provide short length composite plugs for a cemented completion system. A total of 19 stages were successfully stimulated that included plug-and-perf operations with TREX™ Lightning Composite Plugs. Pressure integrity was verified through the Toe-X™ Hydraulic Sleeve at the first stage. The short length of the plugs enabled efficient deployment and millout operations, saving time and reducing risk of stuck debris, while bringing the well online faster.

An operator working in the Marmaton was looking to improve the efficiency of their cemented liner operations. Millout operations to produce a full inside diameter in the casing in a plug-and-perf system introduces operational risk if:

(i) large size cuttings are produced during milling

(ii) there is debris buildup inside the casing that has not been sweeped to surface during flowback

The short length of the Packers Plus TREX Lightning Composite Plugs (13.5-in.) used by the operator facilitated plug deployment and millout operations.

The operator used Lightning Composite Plugs to stimulate 18 stages in their lateral of 4,342 ft, along with a Toe-X Hydraulic Sleeve for the first stage and a PrimeSET™ Liner Hanger to anchor the system at the heel of the well. The Toe-X sleeve was used to pressure test the casing once prior to stimulation—the dual pressure cycle of the Toe-X sleeve enables maximum pressure testing and low pressure opening for stimulation. The casing above the toe sleeve was perforated and treated together as the first stage. The plugs for the subsequent stages were deployed and set using wireline, followed by a total of 60 perforations per stage.

A ball pumped from surface to land in the plug was used to isolate and stimulate each stage.

After successfully running in the system and setting the PrimeSET Liner Hanger, the well was pressure tested to 10,000 psi to verify casing integrity. The well was successfully stimulated with nearly 100,000 bbls of fluid pumped and 4 million lbs of proppant placed, despite the higher than anticipated treating pressures encountered. All 18 plugs were milled out with an average millout time of 2.67 minutes, with favorably sized cuttings seen on surface. The operator was impressed with the results and is planning to complete more of its wells using TREX cemented completion solutions.

石油圈

石油圈