Reactive Downhole Tools, independent supplier of well completion solutions to the global oil and gas industry, has announced a new wellbore clean-up (WBCU) product line, CHIMERA, which has been launched at this year’s OTC.

CHIMERA takes an innovative approach to wellbore clean-up with a range of modular tools encompassing a scraper, brush and magnet. Each product can be run separately prior to completion operations, or as a comprehensive package.

Mike Allen, Chief Executive Officer of Reactive, said: “As Reactive strives to become a full-service completions solutions provider, we realise that the key to this is ensuring our completion tools are performing in the very best environment. It’s because of this that I am incredibly excited to launch of CHIMERA – our full suite of wellbore clean-up tools.”

“Because this market segment is completely new to us, we have engaged experienced professionals in the field to fully support our market entry and have invested an additional $350,000 into our Houston-based facility to support the manufacturing.”

CHIMERA Uni-Blade

CHIMERA Uni-Blade™ is a heavy duty wellbore clean-up scraper suitable for all downhole conditions and with robust, high performance features.

Run separately or as part of a comprehensive wellbore clean-up, the CHIMERA Uni-Blade™ is designed to effectively remove cement and other debris from the casing wall, through reciprocation.

The scraper cage flexes like a spring, to conform to the casing internal surface, to mechanically remove hard debris from the casing. The alloy bronze bearings feature both axial and radial elements to allow extended rotation in harsh environments preventing tool and casing wear. The Heavy Duty version includes an integral string mill. The Standard Duty version comes with a plain external diameter.

- Solid state scraper cage and centralizers, manufactured from a single billet without the need for springs, bolts or pads

- Non-rotating design with high performance alloy bronze bearings, compatible with high temperature and chemical applications

- Optional integral string mill with crushed carbide blades to remove cement

- Available with all API and premium drill pipe connections

BENEFITS

- A properly executed wellbore clean-up mitigates risk during completion operations and the productivity of the well.

- Prevent debris related premature packer setting while RIH

- Assists in chemical cleans action

- Prepare casing wall to ensure packer element sets and mitigate premature elastomer failure

APPLICATIONS

- Pre-completion wellbore clean-up

- Workovers and sidetracking

- Abandonment

- Drilling / milling cement plugs

OPERATIONAL

The CHIMERA Uni-Blade™ scraper is typically the first tool run in a BHA ahead of a brush, magnet or filter tool as it is the most aggressive and most robust tool of this type. As the Scraper Cage enters the casing, the leading centralizer guides and centralizes the tool.

The leading edge of the Scraper Cage blade compresses as it is squeezed into the casing, acting as a self-sprung solid state component. While running in the hole, the self-cleaning teeth scrape the casing wall removing cement and other hard debris. Internal bearings ensure that the Scraper Cage is pulled into the well, rather than pushed, which prevents collapse of the Scraper Cage.

Once at the packer setting depth, the CHIMERA Uni-Blade™ is typically reciprocated three or more times across the critical depth while rotating and reciprocating the string. The bronze alloy bearings have both axial and radial elements to allow extended rotation of the string without damage or wear to the tool or the casing.

The optional integral string mill can be sized to casing drift and is particularly useful when used in a cement milling BHA, as the string mill will help to break up cement and remove any residual debris left by the mill.

CHIMERA™ Brush

The CHIMERA™ Brush is a heavy duty wellbore clean-up brush suitable for all downhole conditions with robust, high performance features.

Run separately or as part of a comprehensive wellbore clean-up, the CHIMERA Brush™ is designed to effectively scrub cement and other debris from the casing wall through reciprocation.

The brush segments are arranged to allow unhindered fluid bypass while circulating through clearly defined flow paths. The brush segments are securely held in dove-tail grooves and cannot come loose downhole. The alloy bronze bearings feature both axial and radial elements to allow extended rotation in harsh environments, preventing tool and casing wear.

- Stainless steel crimped wire brushes to safely scrub the casing wall to remove residual cement, scale and other debris

- Centralizers provide centralization and allow rotation of the tool

body without casing wear

- Non rotating design with high performance alloy bronze bearings compatible with high temperature and chemical applications

- Available with all API and premium drill pipe connections

The CHIMERA™ Brush is typically run in a BHA above a casing scraper as it complements the hard scraping action with a robust scrubbing action targeting residual cement, rust, scale, mud cake or other debris.

As the CHIMERA™ Brush enters the casing, the leading Centralizer guides and centralizes the tool. The brush segments flex as they are squeezed into the casing acting as self-sprung components. The brush segments are arranged into tightly packed blocks to prevent brush wear and allow sufficient bypass of fluid without packing off around the brush.

While running in the hole the CHIMERA™ Brush brushes the casing wall removing cement and other hard debris.

Once at the packer setting depth the CHIMERA™Brush is typically reciprocated three or more times across the critical depth while rotating and reciprocating the string.

The bronze alloy bearings have both axial and radial elements to allow extended rotation of the string without damage or wear to the tool or the casing.

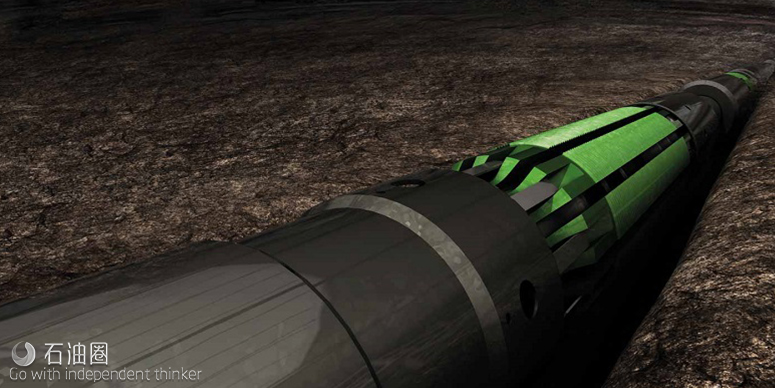

CHIMERA Heli-Mag

CHIMERA Heli-Mag™ is a heavy duty wellbore clean-up magnet suitable for all downhole conditions and with robust, high performance features.

Run separately or as part of a comprehensive wellbore clean-up, the CHIMERA Heli-Mag™ is designed to capture ferrous metal debris in the wellbore.

The magnetic inserts are arranged along ribs to create a debris trap, by encouraging fluid flow between the ribs, maximizing magnet exposure. The magnetic inserts are securely held in tongued grooves and cannot come loose downhole.

Non-rotating sleeves are mounted on alloy bronze bearings, featuring both axial and radial elements, to allow extended rotation in harsh environments, preventing tool and casing wear.

- 16 rows of magnets arranged to trap and retain debris in the wellbore Helically twisted body provides offset for magnets to increase effective area

- Centralizers provide centralization and rotation of the tool body without casing wear

- Non rotating design with high performance alloy bronze bearings compatible with high temperature and chemical applications

- Available with all API and premium drill pipe connections

OPERATIONAL

The CHIMERA Heli-Mag™ can be run alone or as part of a comprehensive wellbore clean-up BHA. It is typically run in a BHA above a casing scraper and brushes as it complements the hard scraping/brushing action to remove ferrous debris from the wellbore.

The CHIMERA Heli-Mag™ is centered in the casing by two non-rotating Centralizers. These guide and centralize the tool, which allows extended rotation without wearing the casing.

While running in the hole or circulating, the well fluid passes along channels between the magnetized ribs capturing ferrous debris. The ribs also prevent debris from being knocked off while circulating or tripping.

The robust tool design, non-rotating centralizers and large debris capacity allow milling of packers, or clean-up of casing windows, to be simple and efficient. Once at surface the magnets can be easily cleaned to allow the tool to be re-run.

石油圈

石油圈