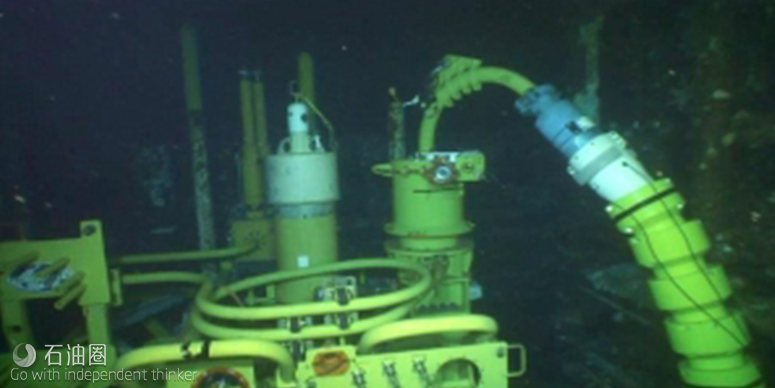

Talos Energy successfully deployed and installed a flexible well jumper using Trendsetter Engineering’s TC7 clamp connectors and TEX gaskets to connect the Mt. Providence subsea well to the Pompano template system.

NOVOS system allows UT grad students to easily incorporate complex algorithms into automation application.

From: Trendsetter

The TC7 clamp connectors were supplied as part of a larger scope of work where Trendsetter Engineering developed new hardware, including a template adapter module and subsea tree connector porch, to assist Talos Energy facilitate long term growth from their existing assets.

The Trendsetter Connection System (TCS) is a family of subsea connector solutions developed to meet industry needs for reliable, innovative connector products. The heart of the TCS is Trendsetter’s proprietary TEX metal‐to‐metal (MTM) gasket system. Trendsetter first introduced its subsea connector and TEX gasket technology to the industry in 2013. These include options from 2” through 16” nominal sizes, as well as multi‐bore, 400°F and 20,000 psi capabilities.

“Trendsetter’s high pressure and high temperature connectors will set a new standard for performance and ease of operability in the most difficult of subsea applications. Through development in conjunction with industry operators, these connectors overcome real‐world challenges under the harshest operating conditions.” said Chris Perry, Product Line Manager, Trendsetter Connection Systems.

The Mt. Providence well, located in 1,850 feet water depth, has since been successfully commissioned and is currently in production. Trendsetter Engineering has been awarded an additional template adapter module to facilitate future tiebacks to the Pompano template.

Trendsetter Engineering, Inc. is a privately owned oil and gas service company based in Houston, Texas which provides specialized subsea hardware and offshore service solutions globally from exploration drilling through abandonment.

Trendsetter’ss continued expansion of the TCS product line meets the ever evolving needs of our customers and industry. The TC2 product line welcomes a hydraulically actuated connector, ideal for intervention and service applications due to emergency quick disconnect capability and optional fluid retention poppets. The clamp connector family has been expanded to include the TC16 to handle large flowline jumpers up to 16” bore. Paired with the development of the TC16 has been a growth of the TEX gasket line to include TEX-13 and TEX-16 sizes.

The Trendsetter Connection System (TCS) is a family of subsea connector solutions developed to meet industry needs for reliable, innovative connector products. All TCS products have been designed around lessons learned, research and feedback on existing subsea connection systems available to the market. The heart of the TCS is Trendsetter’s proprietary metal to metal (MTM) gasket system, TEX. The development of the TCS positions Trendsetter to offer products to our clients which meet and often exceed requirements with unparalleled levels of quality, service, competitive pricing, and fast delivery.

All products are designed, built, and tested in Houston, Texas, USA. The TCS family includes the following products:

• TC2 Collet Connector

• TC7 Clamp Connector

• TC11 Clamp Connector

• TC16 Clamp Connector

TC2 Collet Connector

The TC2 is a compact, small bore connector utilized in service line applications, such as gas lift or chemical injection. The TC2 features a true 2” bore utilizing the TEX-2 gasket. One of the TC2’s key attributes is the innovative collet latch mechanism which provides unparalleled strength in a connector of this size. Using hydraulic or mechanical input, a typical work-class ROV installs the connector into a flush mount receptacle containing the inboard hub. Due to the compact size of the receptacle, the TC2 can be easily incorporated into trees, manifolds, or PLETs and can be oriented vertically or horizontally. An optional alignment key can be bolted on to ensure specific connector orientation, or left off to provide 360 degrees of installation freedom.

As the TC2 utilizes the TEX-2 gasket, backseal testing can be performed just after make-up. The TC2 is rated to 15,000 psi bore pressure and is available in an array of material trims and end connections to suit project requirements. For applications requiring fluid retention during make and break, the TC2 can be equipped with a full pressure rated poppet.

TCS Clamp Connector

The TCS 3-piece clamp connection system is a fully integrated connector product complete with hubs, clamp, and alignment structures in a simple, efficient package. The TCS clamp utilizes a standard API torque tool to make up the lead screw and preload the TEX gasket. The torque bucket is equipped with a simple turn count indicator and mechanical secondary lock.

The clamp housing and softland cylinder are integrated into the outboard alignment structure to save space, simplify packaging and streamline installation. The alignment structure features provisions for the pull down/lift tool interface and windows to facilitate subsea seal change. The TCS clamp connector is available in three sizes and has been qualified to accept a range of gaskets up to 16” ID with sufficient structural capacity to support large jumpers with pipe sizes up to 20”.

The TC7 3-piece clamp is targeted for well and small flowline jumpers, accepting a range of gaskets up to 7” ID and is operated with a standard API Class 5 torque tool. The TC7 is API qualified to:

• 5” bore up to 15,000 psi internal pressure and 400°F

• 7” bore up to 15,000 psi internal pressure and 302°F

The TC11 3-piece clamp system is the mid-range clamp size for larger flowline jumpers. The TC11 accepts gaskets up to 11” ID and is operated with a standard API Class 6 torque tool. The TC11 is API qualified to:

• 9” bore up to 15,000 psi internal pressure and 302°F

• 11” bore up to 10,000 psi internal pressure and 302°F

The TC16 3-piece clamp system is the largest clamp size for gathering and export line jumpers. The TC16 accepts gaskets up to 16” ID and is operated with a standard API Class 7 torque tool. The TC16 is API qualified to:

• 7” dual bores up to 10,000 psi internal pressure and 250°F

• 13” bore up to 7,500 psi internal pressure and 250°F

• 16” bore up to 7,500 psi internal pressure and 250°F

石油圈

石油圈