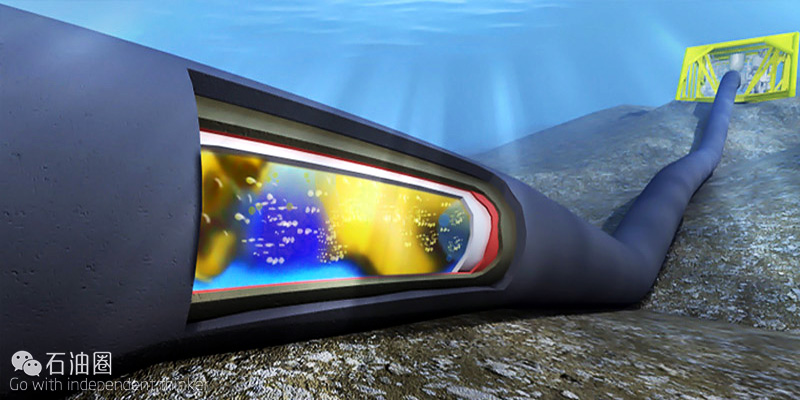

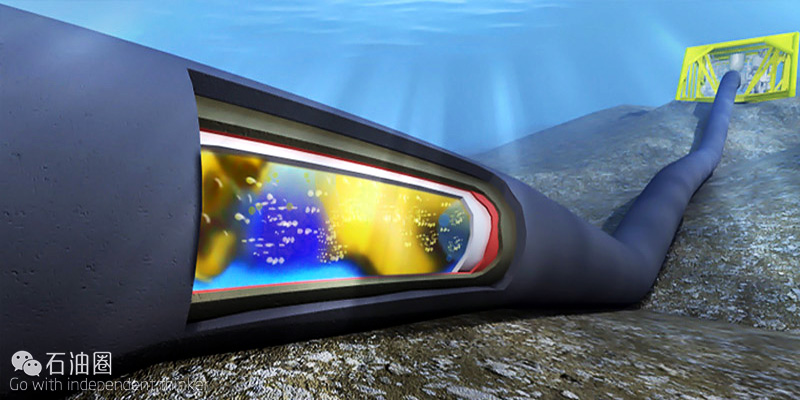

海上生产时,沥青可不是那么招人喜欢。它们沉淀在生产管道、泵和各种配套设备中,如同在顺畅的血液流通网络中长出了结块,堵塞了血管,导致整体机能都出现问题。不过现在有贝克休斯的FATHOM XT SUBSEA525抑制剂来帮忙,可以从根本上抑制沥青沉淀的生成,“小剂量、低频率的治疗”更是让操作更为轻松、简单。

贝克休斯研发的FATHOM XT SUBSEA525抑制剂,性能优异、所需剂量小,可以有效控制深水井中的沥青质沉淀,保证流体的流动更为顺畅,减少生产管线和设备中的堵塞现象,降低治理成本。该抑制剂是专为海上施工所设计,采用了贝克休斯的专利认证技术和严格的实验测评方法,以保证抑制剂能够与海上设备完全兼容,实现低治理频率下的有效性。

在生产中,原油在泵和管道中沉淀出的沥青,会给生产带来严重的问题,比如堵塞流动通道和设备。

[补充:在高含沥青质油藏中,沥青质可以在油气生产整个过程中都发生沉积。近井地带的沥青质沉积会造成渗透率降低,改变岩石润湿性,导致原油采收率降低;油管和流动管线中的沉积可以降低生产速度。另外,在生产设备中沥青质也可发生沉积,例如在分离器中,沥青质可形成稳定乳状液从而造成油水分离问题。]

很多时候我们不得不停工对其进行整治,而为了达到了可接受的治理效果,治理的成本将会非常昂贵。

[补充:目前国内常用的清除沥青质沉积方法有减小剪切力及压力降、定期刮管清除、注入溶剂、注入分散剂等。一般来讲,溶剂苯和硝基苯是抑制沥青质聚沉和清除沥青质沉积的最佳溶剂。经常使用的溶剂有芳香族化合物如苯、甲苯、二甲苯(溶解效果相对较好)等。但是其应用过程中容易出现问题:如,溶剂用量大,处理效果维持时间短,作业频繁和环境污染等。]

同时,这些治理手段在很多时候都只能起到暂时缓解的作用,无法对沥青沉淀问题进行根治。而FATHOM XT抑制剂则可以从根本上减低沥青沉淀的风险,改善流动通道。在生产初期和整个油井生命周期中,FATHOM XT沥青沉淀抑制剂的使用量都可以维持在一个较低的水平上。由于其使用剂量较小,因此也大大简化了供应物流的工作量,减少了现场所需的储存量,同时还降低了处理操作过程中的风险。

“当下,如何在提高产量的同时降低生产成本,这是摆在我们客户面前的最严峻的挑战之一。”贝克休斯上游化学剂部门的副经理Ruben DeVelasco说:“我们新研发的低剂量FATHOM XT抑制剂可以保护海底管道和设备免于遭受沥青沉积的危害,帮助海底脐带管和细小的套管系统免于发生堵塞和失效,从而提高油气生产能力,减少可能的停工时间。”

该新型沥青抑制剂采用了贝克休斯新型实验室评测方法:沥青解析离心稳定性分析法(ACSAA)。通过该方法,可以测试沥青在不同原油类型中的稳定性,监测现场试验效果。基于这些数据,贝克休斯可以针对不同的原油类型和油井状况,更加精确地研究适合它们的抑制剂。

[补充:不同类型的原油中沥青质的稳定性和沉积情况不同,沥青质与胶质一起构成原油的分散相,而石油烯构成原油的连续相。沥青质的沉积取决于原油这一复杂胶体体系的稳定性。原油组成是引起沥青质沉积的诸多原因中的一个主要因素。一般来说,原油中存在含量相近的饱和化合物、芳香族化合物,则认为原油中的沥青质相对稳定。]

新型FATHOM XT SUBSEA525抑制剂是贝克休斯一种最新的高性能沥青抑制剂(除此抑制剂之外,还包括适用于陆地油田的PAO3086型抑制剂)。这是贝克休斯在提高油井效率、优化生产、提高最终采收率上所做出的最新成果。

FATHOM XT SUBSEA525 沥青抑制剂

来自贝克休斯的FATHOM XT SUBSEA525 沥青抑制剂,性能优异、性价比较高。该抑制剂可以与沥青相互作用,可以抑制不受欢迎的沥青沉淀的生成。FATHOM XT SUBSEA525 沥青抑制剂中的有效成分可以减少、抑制生产设备表面的沥青结块和沉淀。与市场上现有的沥青抑制剂相比,只需要较少剂量的该产品,就可以达到相同甚至更好的效果。同时,该产品在产出液中不会出现乳化现象,即,其不会增加油、水的分离工作。

FATHOM XT SUBSEA525沥青抑制剂为一种液体状的有机化学剂,可以用于连续注入的施工作业中。该产品的注入量和注入速率基于沥青问题的严重程度而定。连续注入浓度可以在100ppm到1000ppm的范围内变化,具体要根据产油量的大小来决定,该浓度范围对于大多数油田的施工作业来说都是合理的。

材料兼容性

适用范围

1.金属:316不锈钢,超级双相不锈钢2507,铬镍铁合金 625,304不锈钢,耐热铬镍铁合金 825,双相2205不锈钢,哈氏合金 C-276;

2.塑料:尼龙6,铁氟龙,聚醚醚酮,聚甲醛;石油圈原创www.oilsns.com

3.弹性体:丁腈橡胶N NBR,氢化丁腈橡胶,氯丁橡胶,三元乙丙橡胶,全氟醚橡胶4079,全氟化橡胶505。

不适用的范围

1.金属:4130合金钢,410不锈钢,氮羧酸50;

2.塑料:HD聚乙烯,聚丙烯,PVC;石油圈原创www.oilsns.com

3.弹性体:氟橡胶(VITON)。石油圈原创www.oilsns.com

特色和优势

1.该产品是贝克休斯FATHOM XT系列产品中特别适用于海上油田的沥青抑制剂,其可应用于海底脐带管,治理效果显著,可以保障深水水下生产液流的流动,在多数海底系统中的温度范围内,也可以在高压下保持稳定得性能;

2.抑制沥青沉淀,减少海上油田修井和停工时间;

3.该产品耐温可达 (177°C),可适用于井下的高温环境,是电潜泵抑制沥青沉淀的绝佳选择;

4.该产品具备更优秀的抑制性能,产品的消耗量可以降至最低;

5.该产品在低温高压下环境下均具有较高的稳定性(在典型的低海底温度40°F下,压力最多可达到10,000 psi),可用于海底设备抑制沥青沉淀,减小了海底脐带管失效的风险。

适应性

1.深水;石油圈原创www.oilsns.com

2.脐带注入;石油圈原创www.oilsns.com

3.海底管道;石油圈原创www.oilsns.com

4.海上油田作业。

译者/周诗雨 编辑/魏亚蒙

Baker Hughes’ high-performance, low-dosage FATHOM? XT SUBSEA525 inhibitor can help control asphaltene deposition in deepwater wells, providing better flow assurance and reducing remediation costs by minimizing the risk of blockages in production lines and equipment. The inhibitor was designed and certified for offshore applications using a proprietary qualification protocol and a stringent laboratory evaluation method to enable full compatibility with subsea equipment and effective performance at low treatment levels.

During production, crude oils can deposit asphaltenes inside pumps and pipes, creating serious production issues such as plugged flow lines and clogged equipment, resulting in the need to stop operations and perform a costly remediation procedure to get production back online at acceptable levels.

Many times, these procedures only offer temporary relief. To lessen the risk of asphaltene deposition and enhance flow, the FATHOM XT inhibitor can be applied at low treatment levels during initial production and throughout the life of the well. The low dosage rate simplifies supply logistics, reduces onsite storage and lowers handling risk.

“Today, improving production while minimizing operating costs is one of the most critical challenges facing our customers,” said Ruben DeVelasco, Vice President, Upstream Chemicals at Baker Hughes. “We developed the new, low-dosage FATHOM XT inhibitor to help protect subsea pipelines and other equipment from asphaltene deposition, and umbilical lines and capillary tubing systems from plugging or failures, enhancing our customers’ production output with less remediation downtime than was previously possible.”

This new line of asphaltene inhibitors was developed using the company’s new laboratory evaluation method, the Analytical Centrifuge Stability Analysis for Asphaltenes or ACSAA method. This enables Baker Hughes to evaluate the stability of asphaltenes in various crude oils, and monitor the effectiveness of field treatments. Using these data, Baker Hughes can more precisely develop fit-for-purpose inhibitors for specific crude types and well conditions.

The FATHOM XT SUBSEA525 inhibitor is the first of a new line of high-performance asphaltene inhibitors, which also includes the PAO3086 inhibitor for land-based applications. And it is the latest example of Baker Hughes strategy to improve well efficiency, optimize production and increase ultimate recovery.

FATHOM XT SUBSEA525 asphaltene inhibitor

The high-performing, cost-efficient Baker Hughes FATHOM XT SUBSEA525 asphaltene inhibitor is designed to interact with asphaltenes and suppress the formation of troublesome deposits. The active components of FATHOM XT SUBSEA525 asphaltene inhibitor reduce or inhibit aggregation and deposition on production equipment surfaces. This product can provide equal or better asphaltene inhibition at lower dosage rates than existing asphaltene inhibitors. It is also nonemulsifying in produced water and will not cause oil or water treating upsets.

FATHOM XT SUBSEA525 asphaltene inhibitor is a liquid, organic chemical designed for continuous injection applications. The recommended treatment rates for this product depend on the severity of the asphaltene problem. A continuously injected rate of 100 to 1000 ppm, based on the volume of produced oil, is reasonable for most oilfield applications.

Materials compatibility

Suitable

Metals: 316 stainless steel, super duplex 2507, INCONEL 625, 304 stainless steel, INCOLOY 825, duplex 2205, HASTELLOY C-276

Plastics: nylon 6, TEFLON, PEEK, DELRIN

Elastomers: Buna N NBR, HNBR, neoprene, EPDM, KALREZ? 4079, CHEMRAZ 505

Not suitable

Metals: 4130 alloy steel, 410 stainless steel, NITRONIC? 50

Plastics: HD polyethylene, polypropylene, PVC

Elastomers: FKM (VITON)

Features and benefits

1.Qualified member of the FATHOM XT family of subsea-certified products

– Performs in subsea umbilical applications

– Effective deepwater flow assurance treatment

– Stable at high pressure over the range of temperatures found in many subsea systems

2.Inhibits asphaltene deposits

– Reduces workovers and downtime

3.Capillary approved up to 350°F (177°C) ,

– Suitable for downhole applications

– Excellent choice for systems with submersible pumps

4.Increased product performance

– Optimizes product consumption

5.Excellent low temperature, high pressure stability (up to at least 10,000 psiat typical low subsea temperatures; 40°F)

– Reduces risk of umbilical failure due to product instability

Applications

1.Deep water

2.Umbilical injection

3.Subsea pipelines

4.Offshore

未经允许,不得转载本站任何文章:

石油圈

石油圈