Designed for pad and factory drilling operations, the TelePacer* modular MWD platform addresses the challenges of tight economics inherent to unconventional reservoirs. This platform reduces collision risk, and maximizes sweet-spot exposure with a configurable suite of measurements.

Standard offerings of this single-collar platform are six-axis survey measurements, continuous inclination, toolface, and monitoring of three-axis shock and vibration, stick/slip, and temperature.

Telemetry options for any formation

The TelePacer platform can be configured to transmit data using electromagnetic (EM) or mud pulse (MP) telemetry, depending on formation characteristics.

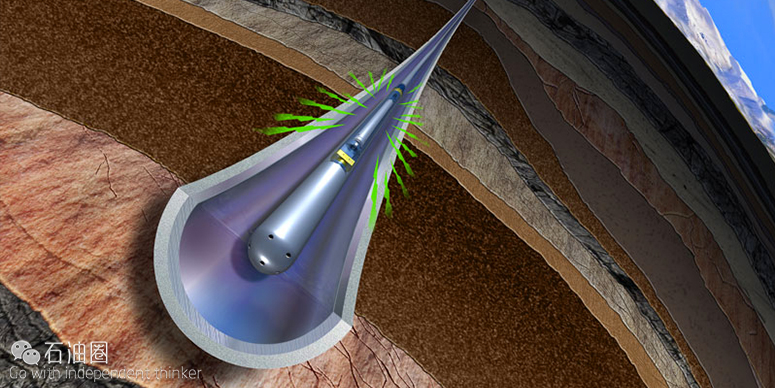

When downhole conditions are compatible with EM telemetry, the TelePacer platform’s Express configuration enables bidirectional communication between surface and the BHA at 16 bps—10 times faster than MP telemetry. With no moving parts, the tool is highly durable. Express EM telemetry also provides reliable data transmission in underbalanced and air drilling applications.

Survey services for increased certainty and reduced risk

Six-axis survey measurements reduce risk by increasing positional certainty with reliable data. To increase lateral and TVD certainty, survey optimization services can be added to provide wellbore separation assurance for achieving production objectives.

For casing exits and other situations with magnetic interference, gravity MWD provides a nonmagnetic azimuth measurement.

Measurements for maximized drilling efficiency and sweet-spot exposure

Total, spectral, and image gamma ray (GR) measurements provide additional information for well placement and formation evaluation. These API-calibrated measurements are highly repeatable, and are transmitted with no impact to drilling efficiency using the TelePacer platform’s Express configuration. Downhole rpm and shock and vibration monitoring allow rapid response to harmful drilling dynamics by adjusting drilling parameters for better drilling performance and risk mitigation.

Total GR measurements enable well steering and correlation by indicating radioactive content. When more advanced evaluation is needed, spectral GR provides insight into mineral composition and clay content to positively identify stratigraphic laminations, which are necessary for effective completion designs.

When in-zone steering is critical, the TelePacer platform can transmit real-time GR images, which reveal formation dips and enable confident geosteering decisions and subsurface model refinement while drilling.

APPLICATIONS

- Continuous and real-time surveying

- Real-time well placement

- Well-to-well correlation

- Formation dip picking

- Drilling dynamics

BENEFITS

- Reduces AFE costs

- Improves drilling performance

- Minimizes collision risk

- Maximizes in-zone exposure

- Eliminates wait time for data transmission

- Enables confident geosteering

- Improves completion quality

FEATURES

- Telemetry: Electromagnetic and mud pulse

- Survey: Six-axis survey, lateral survey optimization, TVD survey optimization, and gravity-based azimuth

- Measurement: Image, spectral, and total gamma ray

- Collar configuration: Single, split, and retrievable

- Stick/slip and three-axis shock and vibration monitoring

- Annular and drillpipe pressure

Express electromagnetic telemetry

The TelePacer* modular MWD platform with Express electromagnetic (EM) telemetry transmits data to surface at up to 16 bps. With transmission rates 10 times faster than mud pulse telemetry, the Express EM telemetry configuration provides higher-resolution real-time images to help well placement teams improve the quality and accuracy of their interpretations.

Save rig time and extend run lengths

Configuring the TelePacer platform with EM telemetry provides fast bidirectional communication between surface and BHA, allowing communication with downhole tools, running advanced logging tools, and reprogramming the platform from surface. This helps you extend run lengths and maintain the high ROP required to efficiently drill unconventional wells.

Receive data reliably

EM data transmission works independently of fluid circulation and employs no moving parts, which offers improved reliability and durability. This configuration is ideal for underbalanced and air drilling applications and eliminates NPT due to the use of multiphase fluids, high-density solids, and heavy LCM.

The use of EM telementry is dependent upon formation characteristics. To ensure the feasibility of using the EM telemetry in your formation, Schlumberger follows a stringent Hazard Analysis and Risk Control process that includes prejob modeling.

ADVANTAGES

- Saves rig time with offline surveying and data rates up to 16 bps

- Provides high-resolution real-time image, spectral, and total gamma ray for improved well placement

- Enables the extension of run lengths with bidirectional communication and reprogramming

- Reliably transmits data in air drilling and during heavy lost circulation material use

- Provides stick/slip and three-axis shock and vibration

- Provides equivalent circulating density and equivalent static density from annular pressure measurements

Gamma ray imaging

With the addition of gamma ray imaging, the TelePacer* modular MWD platform reveals bed crossings, leading to improved decision making and increased production potential. By providing formation dips, GR imaging logs guide real-time well placement and well-to-well correlation.

Improve in-zone percentage and ROP with formation evaluation

Receiving real-time image logs from the TelePacer platform helps you steer within sweet spots to increase in-zone percentage. By avoiding drastic geosteering corrections, sliding is minimized and ROP is improved. These benefits are inherent to using GR imaging, which identifies early signs of changes in lithology and determines well trajectory and wellbore position.

Enhance geological evaluation and completions design

To significantly enhance geological evaluation, spectral GR can be added to the TelePacer platform to provide elemental context (potassium, thorium, and uranium) for changes in the GR imaging log. Together, GR imaging and spectral GR also reveal points of lower, uniform stress, which are ideal for placing fracture clusters.

GR imaging data improve formation evaluation and well placement, leading to opportunties for overall performance improvement.

ADVANTAGES

- Enhances steering within sweet spots using formation dip

- Increases in-zone percentage for enhanced production potential

- Provides focused gamma ray (GR) option for sliding

- Enhance geological evaluation when combined with spectral GR

Spectral gamma ray configuration

The TelePacer* modular MWD platform with spectral gamma ray (GR) provides detailed while-drilling formation structure data. This advanced GR configuration positively identifies stratigraphic laminations along the lateral by giving insight into mineral composition and clay content.

Spectral GR measurements for high-volume reservoirs

Using potassium, thorium, uranium, and total GR measurements, spectral GR provides three additional curves and 2% total GR precision. With this data, you can more efficiently and effectively:

- place laterals and steer within the targeted zone ■ identify lateral formation heterogeneity

- determine clay type

- assess clay volume

- perform accurate well-to-well correlation

- infer total organic carbon when combined with information from pilot wells.

This module is offered within the single-collar TelePacer platform. By adding additional components without increasing the length of the drillstring, the TelePacer platform preserves the tight economics inherent to drilling in high-volume unconventional reservoirs.

ADVANTAGES

- Enables well-to-well correlation and steering within sweet spots

- Provides insight into clay content and total organic carbon

- Measures potassium, uranium, and thorium for elemental analysis

- Simplifies logistics with sourceless sensors and single-collar MWD design

石油圈

石油圈