结合密集射孔与高支撑剂用量的优化完井技术可获得更高的最终采收率,使产量曲线趋势保持平稳。

来自 | DrillingContractor

编译 | TOM 惊蛰

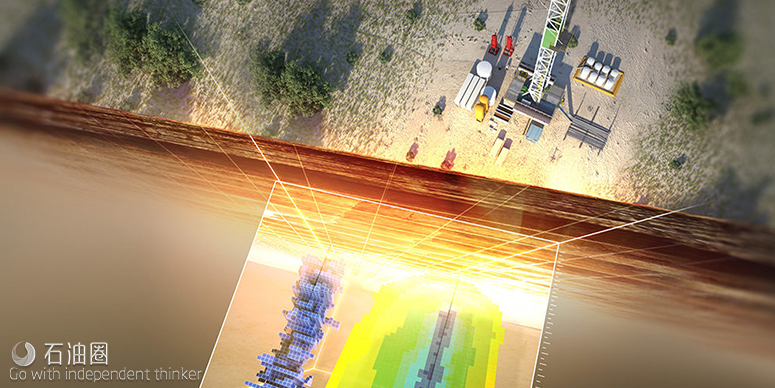

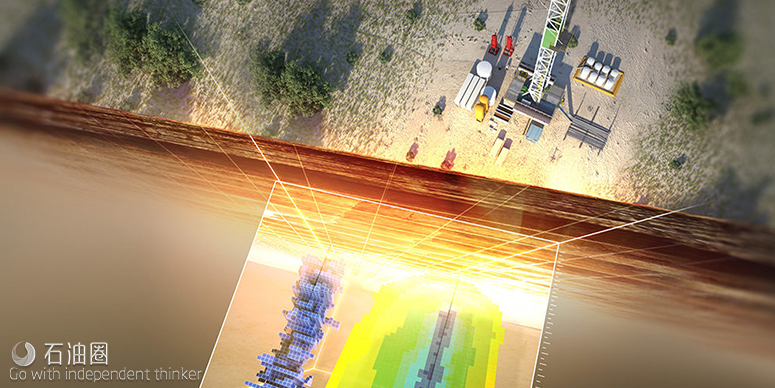

Halliburton技术销售顾问R.J. Cadotte在SPE年度技术展会上表示,Haynesville区块两口井的案例研究表明,采用优化完井技术的新井比老井拥有更高的最终采收率。

优化完井技术即指更长的水平段、更密集的簇间距、更高的支撑剂载荷以及更多的压裂段数,可以显著增加油气井的横向导流裂缝数量以及最终采收率。Halliburton与位于达拉斯的Covey Park Energy油气公司对Haynesville区块的两口井(其中一口完井于2010年,另一口完井于2016年)进行了对比分析,得到了上述结论。此外,该研究还发现先进的完井技术可以减缓Haynesville区块油气井产量的下降趋势。

Cadotte在2017 SPE年度技术展会上表示,Haynesville区块的油藏低渗透性是该区块完井设计持续变革的主要驱动力。他说:“任何没有与裂缝接触的储层,都无助于提高油井的最终采收率。”

由于Haynesville区块的油藏渗透率很低,因此完井设计的重点在于产生更多的横向导流裂缝。然而,实现该目标较为困难,因为Haynesville区块的地层比北美其他页岩区块更软,更具韧性。这种柔软性,再加上高闭合应力梯度,使得该区块的井更容易嵌入支撑剂。在支撑剂浓度较低的区域,裂缝也容易降低缝宽甚至闭合。Cadotte表示,为了克服这些挑战并优化产量,开发商一直试图增加支撑剂的载荷与每口井的压裂段数,同时延长水平段的长度并减少射孔簇的间距。

2011年,Haynesville大部分完井作业的支撑剂用量范围为750至1500磅/英尺。次年,支撑剂的平均用量上升至2500磅/英尺,并保持稳定至2016年,当年的用量再次上升至平均3000磅/英尺。2017年,每个井段的支撑剂用量跃升至3500至5000磅/英尺。增加支撑剂的部主要目的防止裂缝缝宽减小,但这不是唯一的原因。Cadotte说:“开发商增加了越来越多的射孔簇,所以我们必须添加更多的支撑剂来支撑那些额外的射孔簇与额外的裂缝。”

另一方面,射孔簇的间距一直在减少。2011年,簇间距通常在45至65英尺之间。随着时间的推移,作业者意识到过度压裂地层的风险很低,因为渗透率非常低。簇间距在2015年降至30英尺,然后在2016年降至20英尺。目前,在Haynesville区块新的完井作业中,15至20英尺的簇间距是最常见的。由于其超低的地层渗透率,当沿着水平段有更多的起裂点时,可以显著提高Haynesville区块的产量。因为油藏中裂缝的泄油半径有限,当簇间距减小时,作业者可以获得明显的生产效益。

然而,每个压裂段增加射孔簇、降低簇间距会导致射孔效率的降低。随着裂缝的扩展,裂缝与地层的相互作用可以对附近的射孔簇施加应力。Cadotte指出,一些开发商通过减少压裂段长度、增加压裂段数量来应对这一现象。他还表示,段长(桥塞间的距离)从2011年的300至400英尺,降低至2012年的150至200英尺。在此期间,簇间距并没有发生改变。他说:“为了提高射孔簇效率,完井作业增加了压裂段的数量,降低了每段的射孔簇数量。”

作业者想要提高射孔簇效率,另一种常用的方案是使用转向剂。这些药剂使作业者能够确保多个紧密间隔的射孔簇都得到充分的压裂。针对这一点,利用转向剂进行完井作业时,段长通常为100至200英尺,簇间距为15至20英尺。Cadotte说:“我们仍然选择密集的簇间距,并且增加每个压裂段的射孔簇数量。”

与美国其他非常规油气藏相似,Haynesville区块的水平段长度一直在增加。在2015年之前,Haynesville区块井的水平段不超过7500英尺。而如今,作业者经常在一个垂直剖面上钻出长达10000英尺的水平段,而不是在两个分离的垂直剖面上钻出2英里,来实现10000英尺的有效水平段。Cadotte表示,可溶性桥塞的出现是这一趋势的主要推动因素。更长的水平段会产生更高的井下摩阻,这可能会导致连续油管在钻塞时发生屈曲或锁死。可溶性桥塞无需钻塞,则会消除这一风险。

为了弄清上述发展趋势是如何影响Haynesville区块的产量,Halliburton与Covey Park Energy公司对比了路易斯安那州Haynesville区块的传统井与优化井。这两口井相距半英里。传统井于2010年完井,拥有4000英尺的水平段,13个压裂段以及80英尺的簇间距。该井的支撑剂用量为1200磅/英尺。优化井于2016年9月完井,水平段为7100英尺,拥有39个压裂段以及30英尺的簇间距。该井完井作业时采用了分流剂,作业者泵入了3250磅/英尺的支撑剂。总体而言,从传统井到优化井,支撑剂的用量增加了181%,每个射孔簇泵入的支撑剂增加了32%。

传统井与优化井的产量对比表明,优化井的最终采收率更高。Cadotte表示,优化井的产量保持在较高水平,与相同的累计产量相比作图时,曲线较为平缓。事实证明,在水平段上增加更多的射孔簇,并通过转向剂或限制每段射孔簇数量来优化射孔簇效率,大大增加了Haynesville区块油气井的横向导流裂缝数量,提高了最终采收率。”

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

二丫:022-65771089;131-3255-0596

For English, Please click here (展开/收缩)

A case study on two Haynesville wells showed that the newer well, completed with optimized techniques, had a higher EUR than the legacy well, R.J. Cadotte, Technical Sales Advisor for Halliburton, said at the 2017 SPE ATCE in October in San Antonio, Texas.

Optimized completion techniques – including longer laterals, tighter cluster spacing, and higher proppant loads and stage counts – can significantly increase the number of conductive transverse fractures and the estimated ultimate recovery (EUR) of Haynesville wells. The finding was made by Halliburton and Dallas-based E&P company Covey Park Energy in a study comparing two Haynesville wells – one completed in 2010 and one in 2016. Additionally, the study found that modern completion techniques can flatten the decline curve in Haynesville wells.

The evolution of completion designs in the Haynesville have been driven, in large part, by the play’s low reservoir permeability, R.J. Cadotte, Technical Sales Advisor for Halliburton, said during a presentation at the 2017 SPE Annual Technical Conference and Exhibition in San Antonio, Texas, in October. “Any part of the reservoir that’s not contacted with a fracture won’t help increase the EUR of that well,” he said.

Because of the play’s low reservoir permeability, completions in the Haynesville are typically designed to create as many conductive transverse fractures as possible. However, this goal is challenged by the fact that the Haynesville is somewhat softer and more ductile than other North American shale plays. This softness, combined with a high closure stress gradient, makes wells in this region prone to proppant embedment. It also leaves fractures susceptible to losing width or even closing in areas where proppant concentration is low. To overcome these challenges and optimize production, operators have been increasing the proppant load and stage counts per well, while drilling longer laterals and decreasing cluster spacing, Mr Cadotte said.

In 2011, the amount of proppant per lateral foot in the majority of Haynesville completions ranged from 750 to 1,500 lb/ft. The following year, proppant volumes rose to an average 2,500 lb/ft and held steady until 2016, when volumes rose again to an average of 3,000 lb/ft. In 2017, proppant volumes per lateral foot jumped to between 3,500 and 5,000 lb/ft. These increases have come about in part due to the need to prevent fractures from losing width, but that’s not the only reason. “Proppant per lateral foot is increasing so much because we’re adding more and more clusters, so we have to add more proppant to prop those additional clusters and additional fractures.”

On the other hand, the space between these clusters has been decreasing, Mr Cadotte said. In 2011, cluster spacing typically ranged from 45 to 65 ft. “Over time, operators realized that the risk of over-stimulating the formation was low because the permeability was so low,” he added. Cluster spacing decreased to 30 ft in 2015, then to 20 ft in 2016. Now, cluster spacing of 15 to 20 ft is commonplace in new Haynesville completions. With its ultra-low matrix permeability, Haynesville production can be improved when there are more fracture initiation points along the lateral. Because of the limited drainage radius of fractures in the play, operators see production benefits when cluster spacing is decreased.

However, adding more clusters per stage and decreasing cluster spacing can reduce cluster efficiency. As fractures propagate, the interaction with the formation can stress nearby clusters. Some Haynesville operators responded to this phenomenon by decreasing stage length and completing more stages per well, Mr Cadotte pointed out. He noted that stage length – the distance from plug to plug – decreased from 300 to 400 ft in 2011 to 150 to 200 ft in 2012. During this time period, cluster spacing remained the same. “Wells were being completed with more stages and fewer clusters per stage to promote cluster efficiency,” he said.

Another more recent solution operators have adopted to maximize cluster efficiency is the use of diverters. These agents enabled operators to ensure that multiple, tightly spaced clusters would all be sufficiently treated. At this point, wells completed with a diverter have a typical stage length of 100 to 200 ft, with tight cluster spacing of 15 to 20 ft. “We still having tight cluster spacing, and we’re pumping more clusters per stage,” Mr Cadotte said.

Similar to other US unconventional plays, lateral lengths in the Haynesville have been increasing. Prior to 2015, laterals in the Haynesville did not exceed 7,500 ft. Now, operators frequently drill laterals of up to 10,000 ft with one vertical section, rather than drilling two separate 2-mile long vertical sections to achieve a 10,000-ft effective lateral. The advent of dissolvable plugs has been a major enabler of this trend, Mr Cadotte said. Longer laterals create high downhole friction, which can cause helical buckling or lockup in coiled tubing used to drill out non-dissolvable plugs. Dissolvable plugs eliminate the need to drill out plugs.

To see how these trends have impacted Haynesville production, Halliburton and Covey Park Energy compared a legacy and an optimized well in the Louisiana Haynesville. The two wells are located a half-mile apart. The legacy well, completed in 2010, has a 4,000-ft lateral, 13 stages and 80-ft cluster spacing. It was completed with 1,200 lb/ft of proppant. The optimized well, completed in September 2016, was drilled with a 7,100 ft lateral, has 39 stages and 30-ft cluster spacing. A diverter was utilized in this completion. The operator pumped 3,250 lb/ft of proppant. Overall, proppant per lateral foot increased by 181% from the legacy well to the optimized well, and proppant per cluster increased 32%.

A production comparison between the legacy and optimized well showed that the EUR from the optimized well was higher than that of the legacy well. The legacy well had a steep decline curve when its daily gas rate was plotted against cumulative production. The optimized well’s production rate remained high and flat over the same cumulative production volumes, Mr Cadotte said. “Adding more clusters throughout the lateral and optimizing cluster efficiency either by using a diverter or limiting the number of clusters per stage has greatly increased the number of conductive transverse fractures and the EUR of Haynesville wells,” he said.

未经允许,不得转载本站任何文章:

石油圈

石油圈