Efforts to improve proppant transportation have traditionally focused on viscosifying the fluid system, but in today’s tight reservoirs, it’s more typical to use non-viscous slick water treatments. These slick water treatments can be effective, but do present some challenges, including poor proppant transportation, increased settling and duning, and less effective proppant placement. To improve proppant transportation in slick water systems, Trican began to look beyond the fluid system, turning our attention to the proppant. (Trican is a global well service company built upon a foundation of solid corporate values, and a desire to exceed expectations and to nurture a culture of innovation.)

MVPFrac -Taking ordinary proppant to new places

In tight oil and gas formations, it is common to use low-viscosity water-based fluid and proppant combinations pumped at a high rate. These slick water treatments are effective, but do present some challenges. The lack of viscosity can result in poor proppant transportation, leading to increased settling or duning, and less effective proppant placement.

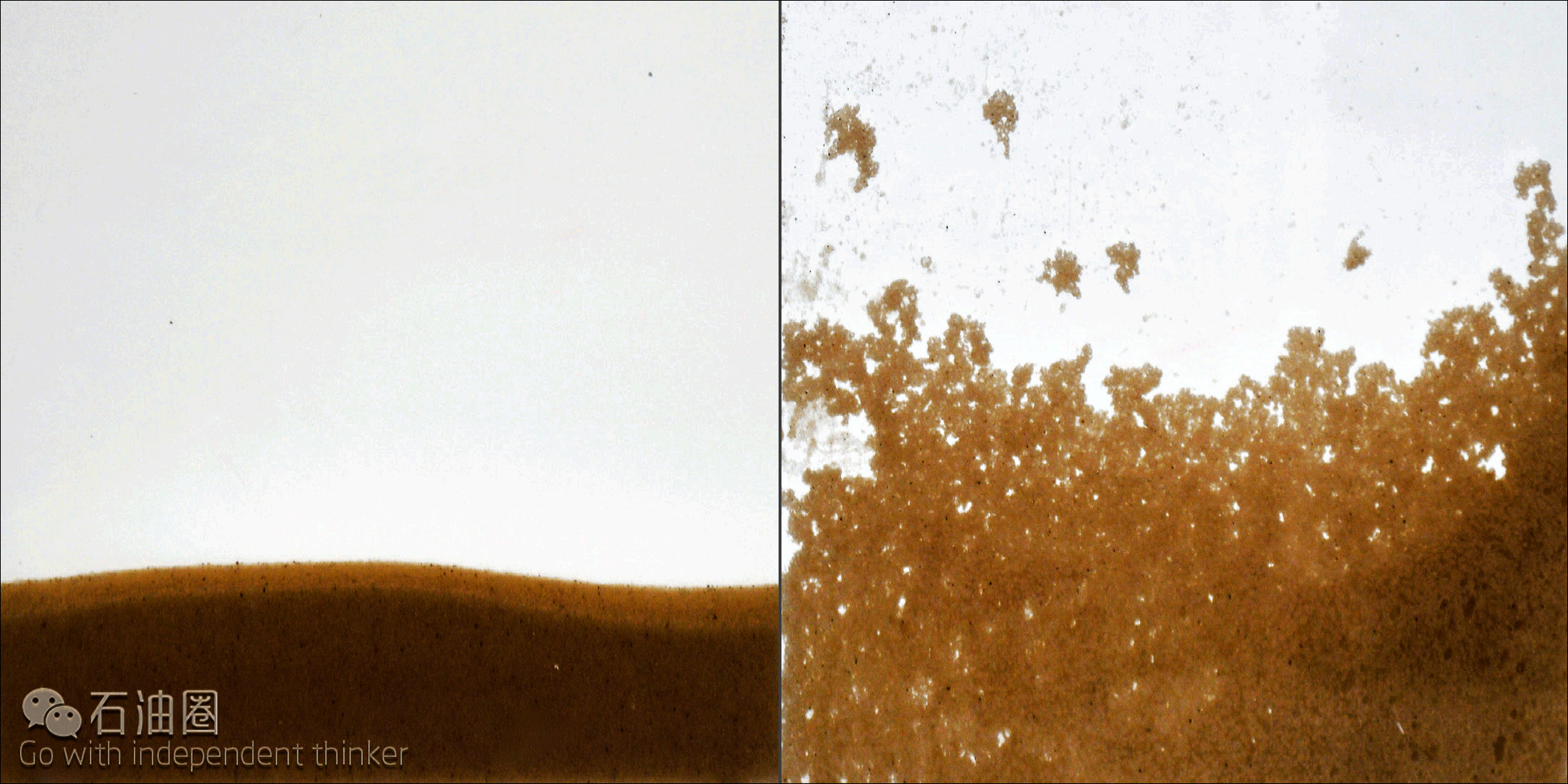

Trican’s proprietary MVP Frac is a simple-to-apply additive that modifies ordinary proppant, making it more buoyant without increasing fluid viscosity. Modifying the design of a traditional slick water treatment by adding a novel chemical to the proppant and 5%-20% nitrogen, the limitations of this type of stimulation fluid can be reduced.

With MVP Frac, a gasphilic coating on the proppant attracts gaseous phases in the fluid. This gives each grain of sand the ability to travel higher and deeper into the reservoir, propping more net pay. Adding a low percentage of nitrogen to the frac fluid is the most effective way of making gas available to surround the proppant for improved transportation. With less proppant settling, greater distribution, and all the benefits of a slick water system, MVP Frac economically increases your production.

MVP Frac– How do you better distribute proppant across your net pay using slick water?

For at least 60 years, oil and gas researchers have been focusing their attention on improving proppant transport by viscosifying frac fluids. With the increased use of slick water and today’s tight reservoirs, it’s time to take another look. Trican has turned its attention to the proppant. MVP Frac? modifies ordinary proppant, creating a gasphilic coating that attracts gaseous phases in the fluid. A thin layer of nitrogen attaches itself to the proppant, giving each grain the buoyancy it needs to be distributed more effectively into the fracture network, increasing your coverage throughout the net pay – and your production. This is a game changer.

MVpFrac advantages

1.Places sand higher and deeper in the reservoir, increasing net pay coverage

2.Advantageous proppant distribution that, upon fracture closure, increases proppant pack conductivity –and net pay coverage

3.Increases regain permeability and conductivity

4.Maintains slick water viscosity, with no additional gels or polymers

5.Reduces water volumes due to increased sand concentration capabilities

6.Reduces sandoffs when using multistage fracturing sleeves, for fewer coiled tubing cleanouts and lower operational costs

7.Proven to increase production

8.Compatible with most standard proppants, water sources and fracturing additives

9.Proppant easily fluidized, eliminating the need for gelled fluid sweeps

10.Simple to apply proprietary technology

With less proppant settling, greater distribution, and all the benefits of a slick water system, MVP Frac economically enhances your production.

Case study:MVP Frac- Saving Time and Money in Slick Water Fracture Treatments

Business Needs

In certain formations, slick water fracture treatments are preferred because they create conductive fractures with minimal proppant pack damage. Slick water treatments involve a low viscosity water-based fluid and proppant combination pumped at a high rate. Although slick water treatments are effective, they can result in increased proppant settling and require large amounts of water. Our customers approached us with the objectives of minimizing water requirements and the operating cost of their horizontal multistage (ball drop) stimulation treatments. To meet these objectives, Trican used our MVP Frac? (Maximum Volume Placement) technology.

Trican Solution

Trican’s MVP Frac? has been designed to dramatically reduce proppant settling that can occur in conventional slick water fracture treatments. The product features a two-part slick water frac system comprised of the following:

1. A non-energized component (FlowRider) that coats and fluidizes the proppant, enhancing distribution throughout the fracture height in the near wellbore region.

2. An energized component consisting of a low percent volume of nitrogen gas that works collaboratively with the FlowRider? treated proppant to transport it farther into the formation.

The MVP Frac fluid system works to fluidize and suspend sand, carrying it deeper, distributing it more effectively within the fracture, and reducing settling and duning. This is accomplished without adding gelled fluid, which is known to damage the proppant pack. With proppant transport significantly improved and settling and duning reduced, our customers were able to successfully use higher concentrations of larger, more conductive sand. The MVP Frac modified treatment schedule allowed for a reduction in the water required, lowering the associated need for transport, storage and heating.

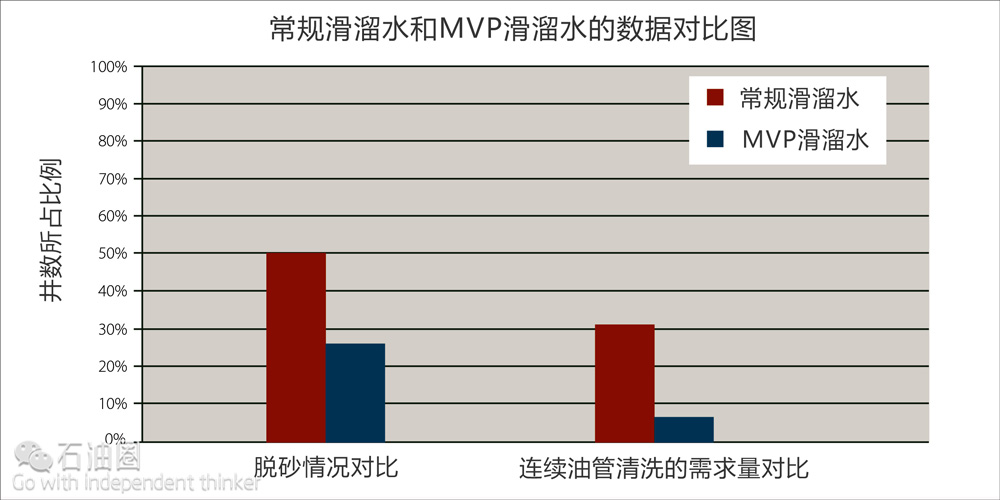

As an additional benefit, data from customers using MVP Frac showed a decrease in sandoff frequency, frac crew downtime, and the need for coiled tubing cleanouts, providing the operator with significant cost savings and lower operational risk. The MVP Frac wells took less time on average to complete than the non-MVP Frac wells (1.19 vs. 1.95 days on average), saving our customer more than $25,000 per well in Trican frac costs, as well as further savings in third party costs.

The Trican Advantage

Using Trican’s MVP Frac fluid system, we were able to enhance proppant transport, allowing the placement of larger and more conductive sand, at higher concentrations. With higher concentrations of sand being transported more efficiently, overall conductivity was increased and water volume was reduced. The reduction in both water requirements and chemical requirements resulted in both a time and cost savings for the customer.

Project Area: Cardium Formation, Canada

Wells: 16 non-MVP wells, 27 MVP wells

Challenges:

1.Minimize water requirement

2.Decrease proppant settling and duning without damaging the proppant pack

3.Minimize frac operation cost

Results:

1.Customers able to use higher concentrations of larger, more conductive sand(s)

2.Reduction in the amount of water required

3.Reduced sand-off frequency, leading to a reduction in downtime

4.Reduced need for coiled tubing cleanouts, significantly reducing project cost

5.Cost and time savings, with lower operational risk

石油圈

石油圈