Well interventions are carried out to increase production from mature fields, for in-well maintenance, as preparation for permanent plugging and abandonment or other rig work, and for bringing new wells online. TechnipFMC has, mainly in the North Sea and together with its alliance partners Island Offshore and Altus Intervention, worked on more than 500 wells and completed more than 3,500 wireline runs. A lot more could be done. There were due to be more than 8,000 subsea wells globally by year-end 2017, with 2,700 in the North Sea, according to Bjarne Neumann, general manager of global intervention, TechnipFMC.

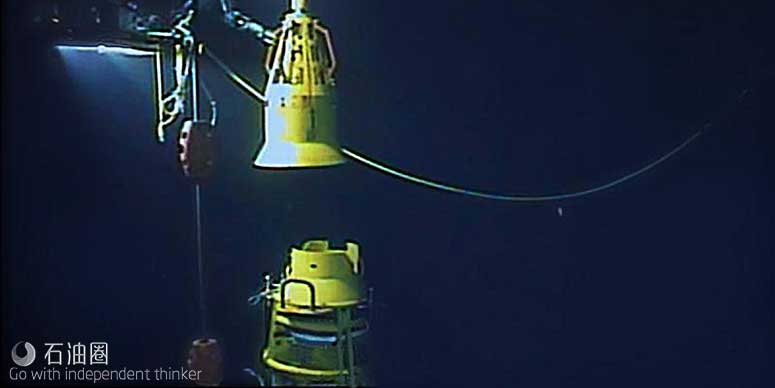

There are 11 7-in. inside diameter subsea riserless light well intervention (RLWI) stacks, five (soon to be six) of which are owned by TechnipFMC, to perform intervention on those wells. TechnipFMC’s RLWI stacks include a patented lubricator system for inserting downhole tool packages into the wellbore, under full pressure and without taking hydrocarbons back to the vessel. The system, and the ancillary communications and controls equipment required, can be deployed from a vessel without the need for drilling or workover risers and anchors. Deployment from a vessel and having less and lighter equipment reduces wellhead fatigue and time and risk related to running and retrieving a workover or marine riser, according to TechnipFMC.

Stacking up experience

TechnipFMC’s RLWI stacks, built in Norway, have been used to complete more than 500 RLWI operations and more than 3,350 wireline runs during the past decade. The company’s first-generation stack is operated on the Island Frontier, with second-generation stacks 2 and 3 on Island Wellserver and Island Constructor, respectively. The third-generation stack 4 is on Island Performer and started its first operations in August 2017, working offshore Australia, alongside a multiskidding system and modular handling tower. Stack 5 was completed at the end of 2017, and TechnipFMC is in the final stages of selecting the vessel on which it will be deployed. Stack 6 will enter the market according to market demand, the firm said. The efficiency of RLWI operations has been improving over the years.

“Back in 2005 it took about 17 to 19 days to carry out the RLWI work from a vessel. Today, these operations can be executed in 5 to 7 days,” Neumann said.

However, TechnipFMC said it’s bringing more improvements to its latest stacks, based on learnings from the North Sea. The new generation stacks (4, 5 and 6) were all upgraded, including making them more modular for ease of maintenance.

“Lessons learned from recertification proved that we need to have more modular systems, so we can do maintenance as we go rather than doing everything at one time,” Neumann said. “The recertification of accumulators, control systems and other components takes a significant amount of time. Making these components modular reduces the recertification time dramatically.”

Going deeper

The stacks can be used on subsea trees from any supplier using an interface adaptor. In addition, all of the stacks from No. 2 and onward have subsea hydraulic power units and subsea hydraulic reservoirs, which reduce the umbilical’s diameter and make them more robust. They also avoid having to pressurize hydraulic fluid on the surface to operate subsea. Closed loop subsea hydraulics also increase response time, which becomes more important as the water depth increases.

“In our view this is an enabler. Rapid response in case of drift-off or drive-off or a well control event is crucial,” Neumann said.

Stacks 4 to 6 also have had further changes to enable deepwater operations.

“It’s a well-known and accepted way of intervention in the North Sea,” Neumann added. “But where it can be a really big win is in deeper water.”

Stacks 4 and onward also have a lower circulation module (LCM) installed. The LCM enables circulation below the well control package and into the wellbore. For temporary plug-and-abandonment (P&A) operations, the LCM allows pumping of heavyweight fluid and cement slurry to kill and isolate the reservoir in the lower abandonment phase to save time before performing the full abandonment, Neumann said.

Stack 4 goes to work

Stack 4, the first new generation design built, was qualified and tested in the Gulf of Mexico down to 2,000 m (6,600 ft) in spring 2016. It started its first commercial work for Inpex offshore Western Australia on the Ichthys Field (pulling plugs) in August 2017, on a 12-well project that was completed by October 2017. Its next project was offshore Western Australia for Woodside Energy in the first quarter of this year as part of a three-year frame agreement for RLWI and subsea services in the Greater Western Flank Phase 2 development, 175 km (108.7 miles) northwest of Dampier, Western Australia.

But in addition to going into deeper waters, RLWI is expanding in capabilities.

“We are about to close the gap between riser-based intervention from a rig to do more operations through riserless intervention than what we could do when we started out,” Neumann said.

This spans from an increasing amount of P&A work to hydraulic pumping and pulling plugs as part of well completion work, freeing up rig time for drilling work, he added.

Open water coiled tubing

With the open water coiled tubing pilot hole drilling performed by Island Offshore Subsea Services with the vessel Island Constructor for Centrica, a new, game-changing opportunity has arisen.

“It will be natural to further explore the possibility of conducting open water coiled tubing operations in subsea wells going forward,” Neumann said. “This will lead to future savings and increased efficiency, especially in combination with P&A operations.”

New technologies will mean that even more work can be moved from the rig.

“We will see a continuing development of intervention methods and robotic downhole tools that allow us to do more in the well without the need for a rig,” he said. “As we move forward, we will increase our scope and build our experience. It’s a very exciting prospect.”

石油圈

石油圈