海洋污染一直是深水开发被诟病的主要方面,相关法规要求也日益严苛。近日,两大石油巨头与科技公司Visuray的合作引起了关注,其推出的新型水泥完整性检测器更是一款颠覆行业认知的强力工具。

来自丨JPT

编译丨Demons 惊蛰

康菲石油和挪威国家石油公司近日与Visuray签署联合开发协议,资助其开发井下水泥固井完整性评估技术。据悉,该技术被称为VR360水泥诊断评估工具,即使间隔多个套管柱,也可以评估水泥固井的完整性。常规超声波测量对于水泥与内部套管壁之间的连接非常敏感,极易受其影响,而VR360将提供全3D水泥状况视图,是常规超声波测量的良好补充。

深水井开发的火热与日益严苛的监管法规是最初刺激该技术发展的原动力。此外,出于经济、法规和环境等方面考虑,成熟井弃置封堵的重要性日益凸显,也促进了该协议的签署。

联合项目于2017年12月中旬开始实施,目标是满足不同尺寸井筒水泥完整性检测的应用,并制造大量的工具原型。该项目预计持续3年,在此期间也可考虑其他石油公司的加入。在工具原型设计、制造完成后,将在石油及天然气井中进行测试。

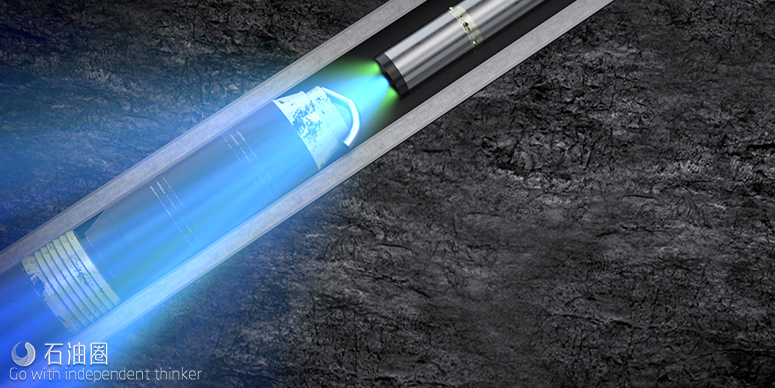

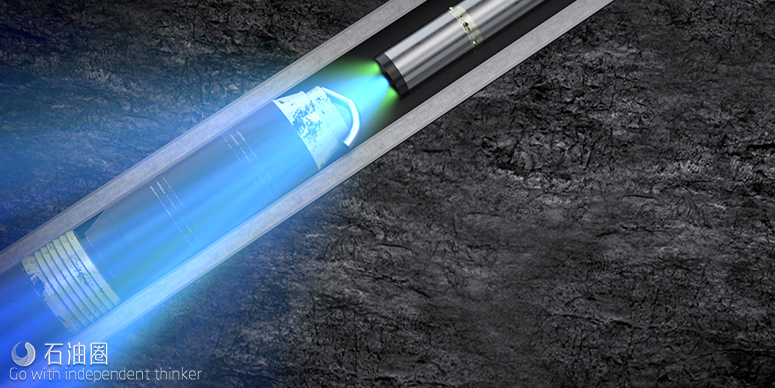

VR360工具将在Visuray公司“井下X射线技术平台”的基础上建立。VR90是该技术平台的第一款X射线诊断工具,目前已在全球范围内广泛应用,并取得了良好的效果。VR90采用X射线成像技术,即使处于不透明液体环境中,也可提供清晰图像。

VR360

VR360诊断性水泥评估工具旨在为水泥评估提供应急评估。在井筒的整个生命周期中,水泥完整性井筒完整性的最重要因素。

以Visuray的井下X射线平台为基础,VR360是第二代产品,通过向外发散X射线完成井筒水泥完整性的评估。即使在双套管井中,也可正常工作,该技术将于2019年投入应用。

VR360克服了当前水泥评估技术的诸多局限性,是业内首款通过直接测量水泥分布完成评估的服务技术。即使是目前最先进的低密度油井水泥固井,也可提供精确结果,其性能远优于现有的超声波技术。得益于监管法规对于深水井完整性的重点关注,VR360得到了最初发展之后,成熟油井的封堵弃置又为该服务开辟了一个新的重要市场。

鉴于该技术的良好应用前景和重要性,Visuray已经获得了大量的行业资金,大大加速了VR360水泥诊断评估工具开发。VR360在单套管和双套管井中测试的成功是该技术的一个重要里程碑,标志着该工具能够直接评估水泥分布并确定机械完整性。

技术平台工作机制

在传统的X射线成像技术(例如在安全或医疗领域中)应用中,通常要将被扫描物体置于X射线源和检测器之间。显而易见,这种设备配置在油井中是不可能实现的。因此Visuray开发了一种称为“基于表面流体成像技术”的替代解决方案,使X射线源和探测器置于被检测物的同一侧。

该技术依赖于目标检测物与X射线源之间流体的散射状况。若流体能够强烈的实现X射线散射,可以检测的X射线强度将增加,意味着视野更加广阔,也可以探测更远的目标。Visuray使用这种高分辨率数据,建立检测物的2D和3D图像。

无论何种油井或是井况如何,该技术平台提供的技术都能获得目标检测物100%准确率的成像图像。

挑战常规

相比于常规技术,Visuray的井下X射线技术平台至少有五项技术突破:

- 首先是一系列可根据客户需求,定制化设计的光子计数X射线探测器,其中包括来自医疗行业的密集像素阵列技术、用于石油行业的定制化小型光电倍增器/闪烁探测器技术等。

- 第二是实现了X射线源小型化,同时保持其高输出。

- 第三点是工具结构紧凑,通过使用高电压,发出高能X射线,检测结果更准确。

- 四是一系列的热交换器和井下冷却器的应用,时刻保持X射线源、检测器工作状况良好。

- 五是Visuray特有的数据分析和处理技术,可以将数据精准转化为2D和3D图像。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

二丫:131-3255-0596;zhanglingyu@cnoocraiborn.com

For English, Please click here (展开/收缩)

ConocoPhillips and Statoil Petroleum have signed a joint-sponsorship-development agreement with Visuray Technology to fund development of a downhole cement-integrity-evaluation technology. The new technology, known as the VR360 Diagnostic Cement Evaluation Tool, will have the capability of evaluating cement integrity even behind multiple casing strings. The tool will provide a full-3D cement map and will complement traditional ultrasonic measurements, which are highly sensitive to the cement bond between the cement and the inner casing wall.

Recent regulatory focus on deepwater wells initially stimulated the development of the technology, but as decommissioning and abandonment of mature wells grows in importance because of economic, regulatory, and environmental concerns, the tool’s potential in such settings spurred the effort to establish the agreement.

The goal of the joint industry project, which became effective in mid-December 2017, is to deliver a number of prototype tools for downhole deployment with a range of external diameters. The project is expected to last 3 years, during which time other oil companies may consider joining the project. The prototypes will be tested in both oil and gas wells.

The VR360 tool will be based upon a suite of X-ray technologies developed by Visuray known as the Downhole X-Ray Platform. Visuray’s first tool from the platform, the VR90 Downhole X-Ray Diagnostic Tool, has been used globally in well-inspection applications. The VR90 service uses an X-ray imaging technique that works in even opaque fluids. Its X-ray backscattering technology can work in any borehole fluid. X-ray forward-scattering is sensitive to the density of the material through which it passes. Because the X-ray source is orders of magnitude brighter than conventional radioisotopes, forward-scatter technology can be used to probe the well environment through multiple casings. The resulting reconstruction of the object’s surface can be displayed as both a 2D surface map and a 3D object with millimetric dimensional accuracy.

VR360

The VR360 diagnostic cement evaluation tool is designed to provide a much-needed step change in cement evaluation. Cement integrity is the most important factor in well safety throughout the life of the well.

Harnessing Visuray’s Downhole X-ray Platform®, the VR360 diagnostic cement evaluation tool is a second-generation Visuray service that radiates X-ray photons radially outward from the tool axis to evaluate cement integrity and detect mechanical anomalies, even in double casing strings. The service will be available in 2019.

The VR360 service overcomes many of the limitations of current cement evaluation technology. It is the first direct measurement of cement distribution, with the ability to evaluate even the most advanced, lightweight oil-well cements, thereby making it superior to current ultrasonic technology. While regulatory focus on deep-water well integrity initially stimulated this development, an increasing focus on the safe abandonment of wells in depleted fields has opened a new and important market for the service.

Significant industry funding has already been secured to accelerate the commercial development of the VR360 diagnostic cement evaluation tool. Key milestones in its technical development have also been reached with full-scale tests in realistic single- and dual-casing well environments, proving the tool’s ability to directly evaluate cement distribution and determine mechanical integrity.

HOW THE PLATFORM WORKS

Conventional X-ray imaging – for example in security or medical applications – involve placing the object to be scanned between the X-ray source and detector. This physical configuration isn’t possible in an oil well. Therefore Visuray scientists developed an alternative solution called “fluid-based surface imaging” that uses an X-ray source and detectors positioned on the same side of the target object.

The technique relies on X-ray scattering within the fluid separating the target object from the X-ray source. Fluids scatter X-rays strongly, so an increase in scattered and detected X-rays means more fluid present in the field of view and correspondingly more distance to the target object. Visuray uses this effect with high-pixel resolution to reconstruct the target object in 2D and 3D with millimetric accuracy.Wherever the well and whatever its condition, the Downhole X-Ray Platform’s family of services will see what’s happening and deliver quality images 100% of the time.

CHALLENGE CONVENTION

Five distinct technological developments and innovations lie at the heart of the Visuray Downhole X-Ray Platform:

- First is a range of custom-designed photon-counting X-ray detectors, which include dense, pixelated arrays derived from technology developed in the medical industry, combined with customized compact photomultiplier/scintillator detectors that are used in the oil industry.

- Second is a range of powerful X-ray sources that have been specially miniaturized and designed for high output.

- Third is a compact, ultra-high voltage power supply enabling the source to emit high-energy X-rays.

- Fourth, is a family of heat exchangers and downhole coolers used to control the temperature of the sources and detectors.

- Fifth is patented data analysis and processing techniques that convert the acquired digital data into 2D and 3D images.

未经允许,不得转载本站任何文章:

石油圈

石油圈