GEODynamics公司推出EVOLV+FracTrap层间隔离系统,从下入、坐封、测试、承压到磨铣,为桥塞的整个作业周期做了优化。

来自 | GEODynamics

编译 | TOM

GEODynamics公司将一项改良的新技术运用到了复合材料压裂桥塞系统中。该技术名为EVOLV+FracTrap层间隔离系统,它在一个工具上集成了投球回收与复合桥塞技术,可以为作业者提供无风险、球阀坐封、桥塞射孔的隔离方案。这种独特的组合通过消除传统风险与拥有额外优势(作业者能够在射孔前测试套管压力),可以节约作业用水与时间。

这种新型压裂桥塞技术引入了下一代完井技术的设计与特性,从下入、坐封、测试、承压到磨铣,为桥塞的整个作业周期做了优化。创新的卡瓦设计避免了提前坐封,而且能够不受限制一直承压。利用球阀技术,作业者可以确保桥塞在射孔作业前已经坐封到位。一旦水力压裂作业完成,设计的斜向引鞋将会为钻穿桥塞锁定方向。钻穿一个完整的复合桥塞,并将其破坏成能够循环出来的合适尺寸,只需8至12分钟不间断的作业。该系统有复合材料卡瓦与铸铁卡瓦两种不同的型号,可根据完井作业需求进行选择。

该系统能够节水、省时间,还可将压裂球与射孔设备一起下入井底,以避免发生无法预料的事件,造成昂贵的修井风险。将球泵送至球座是一项经过现场验证、节约时间的技术,但直到如今,如果泵送失败的话,仍会带来显著的高成本风险。然而,EVOLV+FracTrap系统独有的坐封适配器与投球回收技术降低了该风险。利用这个新系统,只需更少的水与时间就能将压裂球成功泵送至球座上。

这项技术的整体经济效益取决于几个因素,比如套管尺寸、水平段长度以及投球方式(从地面或是沿着水平段下入)。该公司利用计算机建模软件,根据作业的详细参数,来估算作业节省量。对于5.5寸套管的井,从地面将球泵送至井底,保守估计节约了14.5小时作业时间以及12600桶的水。运用此项新技术,每口井可节省高达10万美元。

现场的应用已经证明,在射孔枪没能成功点火的情况,使用EVOLV+FracTrap技术可以为作业者带来价值。该系统已经成功完成超过30次作业。在新系统的钻具组合中,作业者只需遵循简单的作业流程。以2桶/分钟的泵速维持2至3分钟就能成功投球解封。然后再继续按照2桶/分钟的泵速泵送3分钟。当观察泵压已保持稳定,即表明投球已经就位。一旦从井中取出线缆,就证实作业成功,从而避免了利用连续油管磨铣桥塞并重新安装的高成本需求。

系统优势

(1)确保能将球泵送至球座,且没有风险;

(2)投球用水量更少;

(3)每一段作业都能显著节约用水,并降低开泵时间;

(4)无与伦比的工程、制造与质量控制;

(5)正锁定,方便钻出;

(6)可选择复合材料或铸铁卡瓦;

(7)可使用泵送环。

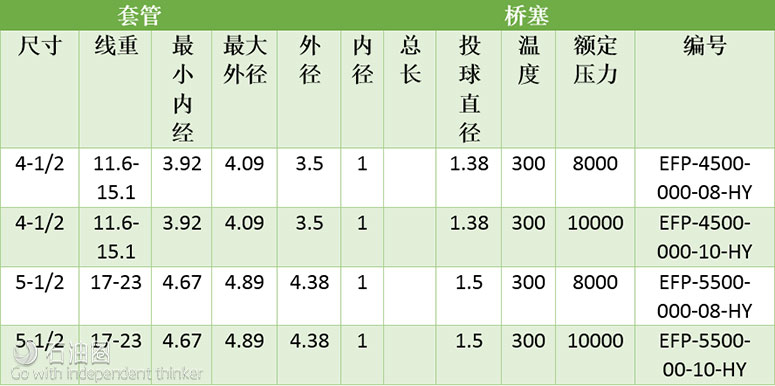

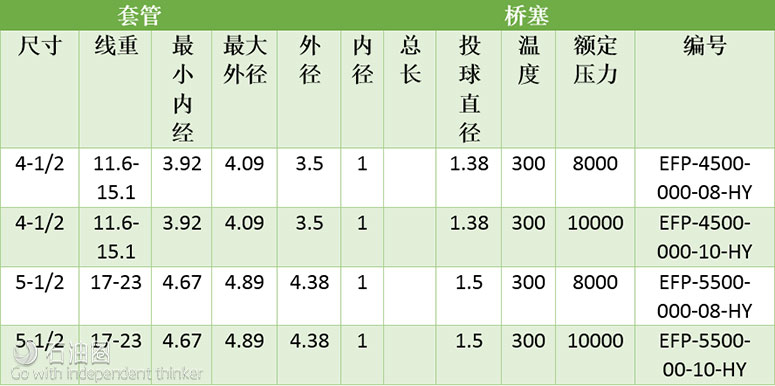

铸铁卡瓦桥塞

上部复合材料下部铸铁卡瓦桥塞

复合材料卡瓦桥塞

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

二丫:131-3255-0596;zhanglingyu@cnoocraiborn.com

大安:131-3203-1392;lishian@cnoocraiborn.com

For English, Please click here (展开/收缩)

GEODynamics introduces new zone isolation technology

GEODynamics has introduced a new and evolutionary technology in composite frac plug systems. Called the EVOLV+FracTrapTM Zone Isolation System, it provides both ball retrieval and composite plug technology in one tool that delivers risk-free, ball-on-seat, plug-and-perf isolation solutions to operators. This unique combination makes water and time savings possible, by eliminating traditional risks with the additional benefit that allows operators to test casing pressure prior to perforating operations.

The new frac plug technology introduces the next generation in well completion design and performance, and is optimized for the entire lifecycle from run, set, test, hold, and mill. The innovative slip technology prevents pre-sets, allowing for indefinite hold time under pressure. Having run ball-on-seat, operators are able to ensure the plug has been properly set and sealed prior to perforating operations. Then, once the hydraulic fracturing procedure has been completed, the mule shoe design provides positive lock-up for drill out of the plug. Consistent drill out times for a fully composite plug is between eight to 12 min. with a favorably sized debris matrix returned from clean out operations. Depending upon well completion requirements, the system is available in either composite or cast-iron slip models.

The system’s water and time-saving technology allows the frac ball to be conveyed down with the perforating equipment to mitigate the risk of costly intervention should an unforeseen event prevent injecting into the well. The method of pumping the ball-on-seat is a field-proven and time-saving technique; however, until now it bore a considerable cost risk should injection failures occur. EVOLV+FracTrap’s patented setting adapter and ball retrieval technology reduces this risk. Utilizing this new system, the frac ball confidently can be run-on-seat using significantly less water and time.

The overall economic benefit of the technology varies depending upon several factors, such as size of casing, length of lateral, and whether the ball is being pumped from surface or only along the lateral. The company uses computer modeling software to estimate job savings based on detailed input that is specific to the well’s construction. Conservative estimates for a well with 5.5-in. casing and the ball pumped from the surface show savings of 14.5 hr of pumping time and over 12,600 bbl of water. Employing the new technology has potential savings up to $100,000 per well.

EVOLV+FracTrap technology has proven its worth to operators that have employed the system when perforating guns have failed to fire, where already over 30 successful ball retrievals have been performed. With the new system in the tool string, operators followed simple retrieval procedures. Successful ball retrieval occurs by flowing at a rate of approximately two bbl/min. for two to three min. Following the retrieval process, fluid was then injected into the well at two bbl/min for three minutes. No increase in pressure was observed, indicating the ball had been caught. Once the wireline was pulled from the well, it was confirmed, mitigating the costly need to mill the plug and reset a new one on coiled tubing.

System Advantages:

Confidently run the fracball in place without risk

Less water to seat the ball

Significant water savings on every stage, along with pump time savings

Unmatched engineering, manufacturing and quality control

Positive lock up for drill out

Composite or cast iron slip options available

Available with pump down ring

未经允许,不得转载本站任何文章:

石油圈

石油圈