Environmental BioTechnologies Inc.(EBT) is a service provider of surface geo- microbial surveys for the oil and gas industry. For over 20 years EBT has delivered surface microbial geochemistry exploration surveys for the oil and gas industry with our proprietary hydrocarbon exploration process called the MET process (Microbial Exploration Technology), and has recently adapted the MET process to be used for uranium exploration as well.

Located in Lodi, California USA. EBT has conducted MET surveys in over 10 countries covering over 17 million acres, with a MET-recommended well completion rate over 80% success worldwide and a dry hole prediction rate of 93%. MET surveys can be used for both on and offshore geo-microbial surveys, and has been used in a wide variety of environments; Canadian tundra, Ecuadorian rainforests, Peruvian deserts, and oceanic sediments.

The MET process is also an environmentally friendly method of exploration, as there is no special equipment, chemicals, or explosives used during sample collection. The MET technology is able to judge the microbial populations of hydrocarbon degrading microbes present within the soils. Geo-microbial surveys are a cost effective way to survey over a large area. The MET process is cost effective, precise, accurate, and timely. A large scale MET survey, at maximun sample spacing can get analytical costs as low as $3-5 per acre (depending upon location characteristics and sampling densities), and often can take only 2-3 weeks to complete analysis, interpretation, graphics, and reports once the final sample shipment has arrived in EBTs laboratory.

MET surveys are a useful tool when used in conjunction with seismic surveys. Geo-microbial surveys are able to identify surface anomalies, and when compared with the results of a seismic survey you would be able to see where surface signals correlate with sub-surface structures identified by the seismic survey. With only the seismic survey you would be able to identify sub-surface structures, but without the geo-microbial survey you would not know if the sub-surface structure is charged with hydrocarbons. Please browse our website and see how EBT can assist your exploration activities.

Microbial exploration

MET is based on three physical and biological principles:

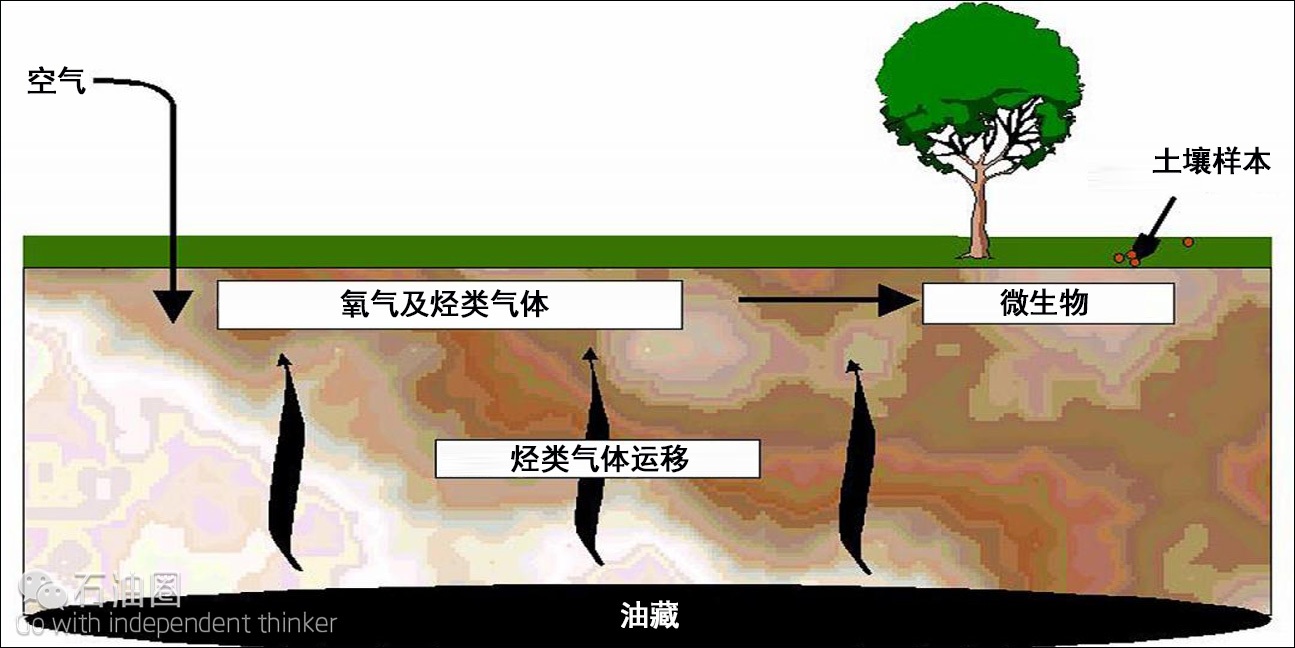

1.The technology assumes that oil or gas reservoirs will have a certain amount of hydrocarbon gas that migrates to the surface .

2.These gaseous hydrocarbons serve as a nutrient source to soil microorganisms in aerobic nearsurface zones.

3.Once an oil or gas reservoir undergoes production, the near surface MET signal over the produced area of the reservoir decreases. Gas now migrates more easily through the wellbore rather than through the overburden.

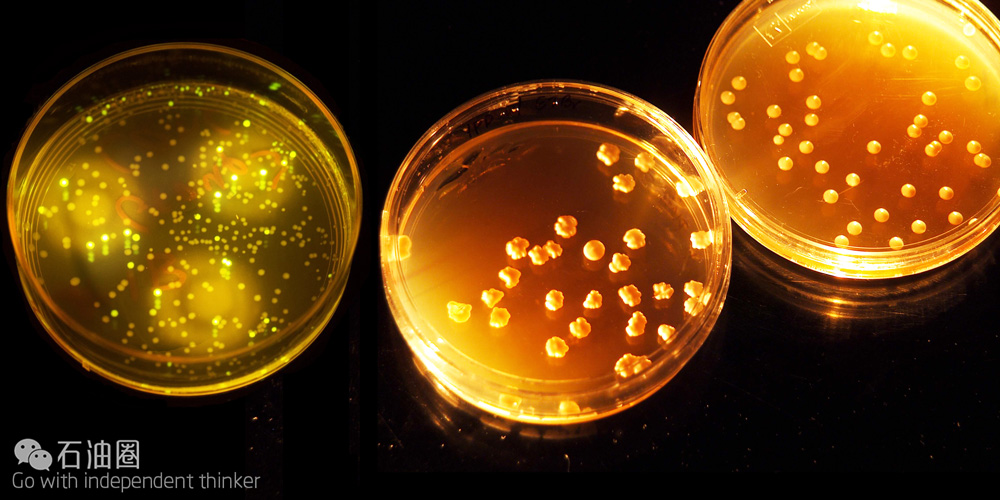

MET technology is capable of identifying the level of microorganisms present in nearsurface soils in response to the amount of hydrocarbon gases migrating from subsurface petroleum deposits. EBT develops the MET value by judging the population levels of the hydrocarbondegrading soil microorganisms.

With these principles, MET survey technology can be deployed both onshore and offshore. For offshore surveys there is enough oxygen in the water to create an aerobic environment in the sediment layers for the microorganisms to flourish, as long as a gaseous hydrocarbon nutrient source is available.

In all survey work the soil samples have to be collected deep enough to eliminate error from surface contaminants and organic materials. The soil samples, however, cannot be taken from a depth below where oxygen can permeate the soil column.

After the laboratory analysis, EBT generates an MET value for each sample location. EBT then uses these MET values to create seven maps to analyze how the individual MET values compare to the entirety of the MET survey.

The final map that EBT produces is called the percent probability of drilling success map (%PS Map). This %PS Map is how EBT evaluates and recommends well locations.

Locations that have a %PS value of 45 or greater are recommended for exploratory wells. For development wells, EBT uses a lower %PS value because of the effect the producing wells have of drawing the signal strength away from the surface. As mentioned, gas will take the path of least resistance to the surface.

Supplemental technology

MET survey technology is often deployed jointly with seismic surveys. MET technology can identify areas of hydrocarbon interest on the surface, but it cannot define the structures or traps that are involved in the subsurface.

Conversely, seismic surveys can identify the subsurface structures and traps but are less effective in defining how well traps and structures are charged with hydrocarbons. Using both seismic and MET together improves the success rates, compared with using either technology alone.

Given the price of an MET survey, $35 an acre, and better definition for further seismic shoots, MET surveys are often carried out before the seismic survey.

In addition, both surveys can be conducted simultaneously, as in the case for Block 15. EBT trained the seismic crew how to collect MET soil samples. As the seismic crew conducted its survey, it collected the MET soil samples to be sent to EBT’s laboratory.

This method eliminates the need to mobilize two field crews but removes the benefit of using the MET survey to design where to conduct the seismic survey. The cost of an MET survey when run in conjunction with a seismic project is in the range of $400600/km, a fraction of the cost of shooting seismic.

The MET Process

1.First, oil and gas reservoirs naturally vent hydrocarbon gas to the surface via vertical gas migration.

2.Second, the hydrocarbon gas serves as a nutrient source for surface microorganisms in near surface aerobic zones.

3.Third, there is a strong correlation between the presence of the microorganism populations and the presence of a hydrocarbon anomalies.

The MET Process – Offshore

1.For offshore MET surveys there is no significant difference in the methodology.

2.Samples collected underwater are still in an aerobic zone.

3.Water supplies the oxygen for the underwater aerobic zone.

4.The soil bacteria quantified by the MET process will be present in underwater soils, as long as there are hydrocarbon gases present in the aerobic zone.

Benefits of the MET Technology

1.Proven technology that is effective, with timely results.

2.Ease of soil sample collection.

3.Precise coverage of large areas.

4.Low survey cost includes analytical, graphics, and report.

Correlating MET Data with Drilling Results for Targeted Structure and Prospect

As the Structure and Isopach map provided by the government of Saskatchewan shows, this prospect is located in a known area for the Radcliff , Midale, and Frobisher structures, as shown in Map 2. This prospect has a Midale formation structure boundary that passes right through heart of our lease and is located in the middle of the Radcliff formation. The combination of the fact that this prospect is located over these two productive formations and shows a strong MET signal indicates that there is an exploitable hydrocarbon accumulation in this location with the potential for a multi-horizon well from two productive structures.

According to the government of Saskatchewan Radcliff formation wells have an average cumulative production of 130 mbbls, and Midale formation wells have an average cumulative production of 160 mbbls. What makes this an even more exciting prospect is that there is prolific production within one mile of this lease. These wells exceed the general average production numbers with a 1.5 MMBO well and several more wells with production over 300 MBO each*. The regional drilling and production results are shown in the following section.

Prospect Overview

Over the past 15 years there have been 13 post-survey wells that have been drilled and completed in these surrounding sections and 1 dry well. Of these 14 wells, the 13 completed wells were drilled in MET recommended locations, while the dry well was drilled in a MET non-recommended location. These operators did not use EBT’s MET data for the well site selection of these wells in support of the drilling and these results strongly confirm the ability of EBT’s MET technology to identify successful wells. By leveraging the historical drilling success of this proprietary technology combined with industries successful drilling around this location, EBT believes that this drilling prospect has a high potential of being successfully completed and generating lucrative returns to its investors. The estimated financial returns are shown in the Prospect Summary section at the end of this prospectus.

石油圈

石油圈