EmPulse® —MULTI STRING IMAGING

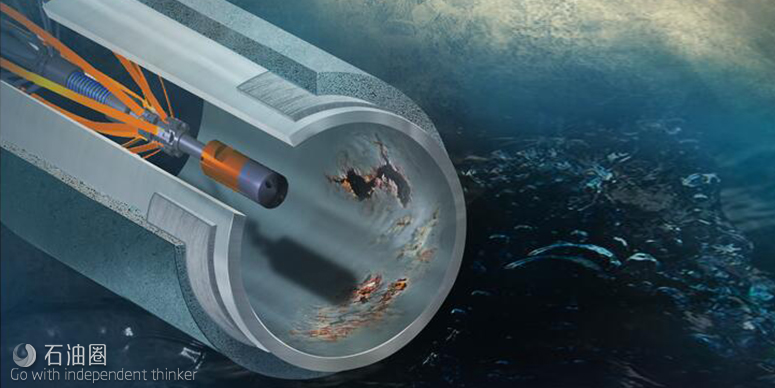

EmPulse® is a slim downhole tool designed to scan metal around its sensor. The tool is run through the tubing to detect metal loss due to corrosion or other factors.

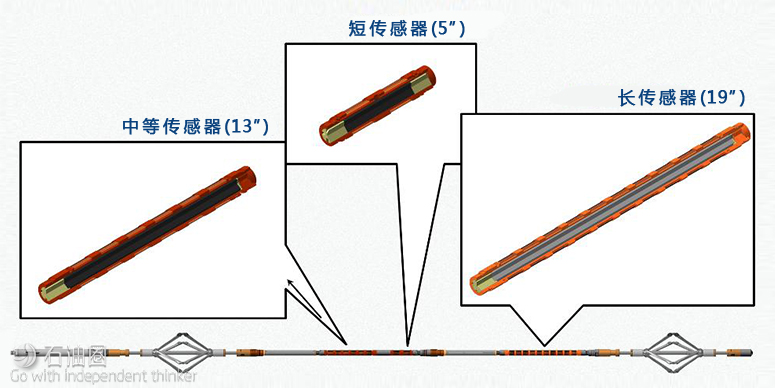

THE TOOL EMPLOYS THREE SENSORS (SEE FIGURE BELOW) BASED ON SHORT, MEDIUM AND LONG, HIGH-EFFICIENCY, FAST-RESPONSE COILS. THESE COILS ALTERNATELY GENERATE ELECTROMAGNETIC PULSES. THE DECAY OF A PULSE IS GOVERNED BY THE PROPERTIES OF THE TUBING AND CASINGS SURROUNDING THE TOOL. METAL LOSS DUE TO CORROSION CAUSES A FASTER DECAY.

The short 5″ sensor generates short electromagnetic pulses to survey tubing and casing of small diameters up to 5″. The length of the sensor defines the minimum detectable size of defects, which is 0.9″ for the short one.

The medium 13″ sensor is optimised to scan metal barriers of up to 10″ in diameter. As this sensor module generates electromagnetic pulses of higher amplitude and longer duration than the short one, it can detect defects in the more distant second and third barriers of 2–10″ diameter. The minimum detectable size of defects is 1.8″.

The long 19″ sensor generates the longest electromagnetic pulses of highest amplitude and detects responses from metal barriers appearing in magnetisation decays at late times. This sensor is designed to scan metal barriers upto 18 5/8” in diameter with a total thickness of up to 2″

Collars, X-nipples and other completion components can be identified directlyin raw time responses. However, metal loss (such as due to corrosion or perforations) cannot be displayed directly, and the data must first be processed using TGT’s proprietary software to simulate the response. A comparison of logging data and the simulated response then reveals metal loss, even behind multiple barriers.

The informative DELTA panel shows differences between simulated and real responses. This panel provides sharp image contrast and shows metal losses in fine detail.

EmPulse® is a memory tool and, therefore, can be conveyed on slickline.This feature greatly reduces operating costs allowing the EmPulse® to be used as a diagnostic tool to assess well integrity and prevent failures before they occur. The tool is also equipped with a pressure sensor to detect pressure drops due to tubing leaks and with a temperature sensor to detect deviations from the geothermal profile outside the tubing. In addition, the tool can be run in combination with the Spectral Noise Logging (SNL HD) memory tool to detect fluid movements, even behind multiple barriers, providing a unique through-tubing well integrity suite implemented with a slim memory toolstring.

Key features of the EmPulse system:

(1)Ultra-fast sensor technology with rapid relaxation time;

(2) ‘Time-domain’ measuring technique;

(3)Complete solution of Maxwell’s equations across the entire response time window. Maxwell’s equations predict the relationship between electricity, magnetism and the surrounding environment;

(4)Three sensors, leading to improved accuracy and a more robust and accurate measurement solution;

(5)Designed and manufactured in-house as well as a large characterisation and calibration facility to ensure exact responses to special pipe configurations and pipe defect scenarios. TGT has total control over both its manufacturing and software that ensures a more effective and controllable solution;

(6)Many of the industry’s leading ‘through-barrier’ log analysts, providing a complete end-to-end well diagnostics solution for operators.

TGT ANNOUNCES MIDDLE EAST WELL DIAGNOSTICS BREAKTHROUGH

EmPulse® multi-barrier integrity diagnostics system successfully tested on 28% chromium tubulars, ensuring asset integrity and better well performance in challenging production environments.

TGT Oilfield Services, the market leader in through-barrier diagnostic systems, has announced the successful validation of its electromagnetic EmPulse® well inspection system in high chromium tubulars.

In three Middle East deployments – one an operator witnessed ‘yard test’ and the other in two live wells – TGT engineers demonstrated that the EmPulse system can quantitatively determine the individual tubular thickness of up to four concentric barriers, even when there are high amounts of chrome in the tubulars.

Ken Feather, TGT’s chief marketing officer commented, “This achievement marks an important industry breakthrough as operators endeavour to protect well integrity in ever more challenging production environments. Increasing chromium content helps to protect well completions from highly-corrosive fluids, such as carbon dioxide, hydrogen sulphide and chloride—but high-chrome can cause serious problems for ordinary electromagnetic pipe inspection systems.”

He continues, “It’s essential that operators can access integrity inspection systems that work reliably and accurately throughout the well system in all environments and materials, especially where corrosive and toxic fluids are involved. This is why we created the EmPulse diagnostic platform.”

The increase in chrome and the resulting decrease in ferrous content causes electromagnetic [EM] signals to decay too quickly for ordinary EM inspection systems. Designed and manufactured completely in-house by TGT scientists and engineers, the EmPulse system combines ultra-fast sensor technology with ‘time-domain’ measurement techniques to capture EM signals rapidly and accurately in a wide range of pipe materials, including those with high-chrome content. This enables operators to evaluate pipe thickness and metal loss in multiple casing strings simultaneously, ensuring long-term well performance even in the most challenging production environments.

“The ability of EmPulse technology to make measurements when facing specialised materials in certain well tubulars marks a significant breakthrough for TGT and the industry as a whole,” said Simon Sparke, TGT integrity expert and coordinator of the high-chrome testing programme.

“That’s why today’s test results are so important, demonstrating how the EmPulse system of sensors, measuring techniques, processing and answer products can deliver fast response corrosion information, address a crucial information gap, and help protect well integrity in challenging production environments. We anticipate that EmPulse will be particularly applicable for the Middle East operators, and also some fields in the Gulf of Mexico, the North Sea and offshore Brazil.”

TGT’s EmPulse technology adds considerably to the integrity security of a well by providing barrier-by-barrier visualisation of the well operating envelope at the time of logging. The time-based measurements, enabling the system to quantify metal loss in up to four barriers independently and deliver highly sensitive and fast response measurements, brings with it significant advantages over frequency-based measurements offered by other systems.

The Middle East operator witnessed ‘yard test’ consisted of a 28% chrome pipe with built-in mechanical defects where the high-speed EM sensor technology of EmPulse confirmed and correctly identified the man-made problems in a controlled environment.

The second operation took place in two live Middle East wells in a very high hydrogen sulphide gas production scenario with 28% chrome tubulars. In this case, the EmPulse system again functioned as planned, and recorded the status of three well barriers. Additionally, a multi-finger caliper recording confirmed the electromagnetic results for the condition of the inner pipe.

石油圈

石油圈