Well-Centric develops innovative tool to deliver dual milling and clean out solution

Improved solution to traditional surface milling tools

Well-Centric, a leading independent specialist in well integrity and production technology solutions for the oil and gas industry, will launch a new compact milling tool at the SPE ICoTA Well Intervention Conference this month.

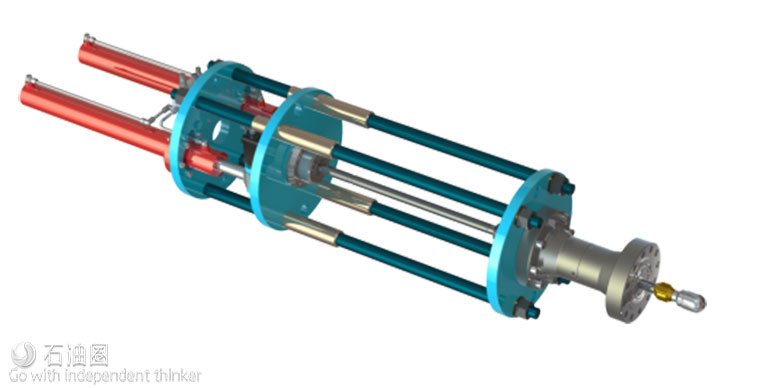

The Well-Centric Gate Valve Milling Tool is a milling tool designed to provide access to restricted wells by drilling through stuck gate valves or other blockages. Stuck valves can result in a well being out of action for months, if not years, with lost production potentially amounting to millions. The Gate Valve Milling Tool helps reinstate production safely, quickly and efficiently with minimal operator downtime.

Originally developed as a solution to mill through stuck gate valves, this innovative tool has several further applications. Mill bits can be changed out for magnets, brushes or scrapers, providing additional clean-out capability. Additional drill rods can also be added to reach deeper into the well, past the Xmas tree, to mill obstructions at the tubing hanger.

The Gate Valve Milling Tool can be used both onshore and offshore and boasts a modular design, small footprint and extended stroke to reach deeper into the wellbore. Lubricators are not required to install drill rods, enabling more efficient rig-up and a reduced overall footprint.

With an incredibly powerful hydraulic motor and safer operation, thanks to fewer exposed rotating parts, the Gate Valve Milling Tool means demanding jobs are completed quickly and efficiently, milling out a gate valve in under three hours.

Used in conjunction with relevant valves/pump-in subs to maintain well control, the new tool is the latest in a string of technology innovations and well integrity solutions that Well-Centric has brought to the market since its inception. Others include an Annulus Lubrication Filling (ALF) Valve for more efficient annulus top-up operations and a range of conductor and wellhead stabilising repair clamps.

Well-Centric’s Gate Valve Milling Tool is a surface milling tool. It is designed to provide access to obstructed wells by milling through stuck or inoperable gate valves or other blockages which compromise the integrity of a well.

The Milling Tool is unique in its design. With no lubricator required to add drill rods, a powerful motor and a selection of mill bit functions, this compact tool is perfect for regaining well entry and restoring wellbore integrity even in the toughest scenarios.

This innovative product includes several applications where bits can be changed out for magnets, brushes or scrapers, providing additional clean-out capability. The Gate Valve Milling Tool helps reinstate production safely, quickly and efficiently with minimal operator downtime.

Benefits

Quicker, easier and safer to rig-up and rig-down

Reduced milling time restores wellbore integrity quickly – drills through gate valves in under 3 hours

Shut-in wells are brought back online quickly and easily

Reduces operational costs and non-productive time

Requires fewer personnel

Reduced footprint, operable in smaller, restrictive spaces

Multiple mill bit functions increase operational efficiency

Barriers provided for live-well entry

Features

Onshore or offshore use

Drills through stuck or inoperable gate valves and other near wellhead blockages

Drills through restrictions up to 7”

Operable in live well conditions

Powerful hydraulic motor

Custom mill bits with specialist, super hard, cutting faces allow milling through tough tungsten carbide faced gates

A cutting fluid injection system cools and lubricates the mill while simultaneously clearing debris from the mill zone

A selection of mill bit functions enables multiple operations to take place with one tool, including milling, scraping, brushing and debris and swarf removal

Failsafe pull-to-shear milling bits prevent getting stuck in hole

Side entry drill rod installation means no lubricator is required, saving rig-up height

Specialist triple primary seal assembly with conventional backup seal assembly, allowing in-situ replacement if required

Used in conjunction with relevant valves/pump-in subs to maintain well control and integrity.

石油圈

石油圈