Microproppants Unlock Potential Of Secondary Fractures

Proppant selection has long been considered one of the critical success factors in well stimulation. Over the years, proppants have ranged in size from 12/20 mesh and 16/30 mesh all the way down to much finer 100 mesh, which is very common. As the industry has seen the demand for proppant continue to move to finer mesh sizes, U.S. Silica decided to investigate what products might be available that are smaller than the 100-mesh product offered today and could easily be utilized in fracture stimulation design to access an existing or induced fracture network that remains untapped.

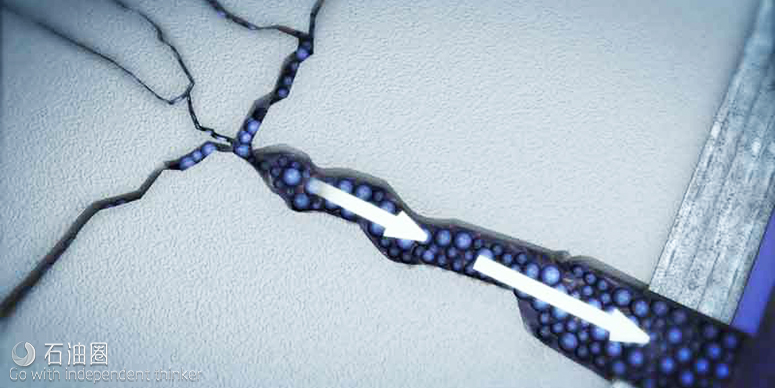

As the oil and gas industry learns more about unconventional shale fracturing, it appears that an extensive naturally occurring secondary fracture network of induced and natural fissures is present in many shale wells. These secondary fracture networks have been estimated to take as much as 90% of the total liquid volume pumped during a hydraulic fracturing stimulation. However, just because the fracturing fluid goes into these secondary fractures doesn’t mean the proppant does. These secondary fracture widths are estimated to be in the low micron range (50 μm). Even the smallest of conventional proppants used today would be too large to access this fracture network and provide stimulated production pathways to the main fracture.

If the proppant cannot go into the secondary natural fractures due to its size, then the secondary fracture network will most likely close and constrict upon pressure drawdown, leaving a majority of the stimulated reservoir volume (SRV) ineffective or wasted during the production phase. To take full advantage of the SRV and access the full potential that lies in the secondary network, a smaller proppant is required to penetrate, stimulate and dilate this vast untouched reservoir volume.

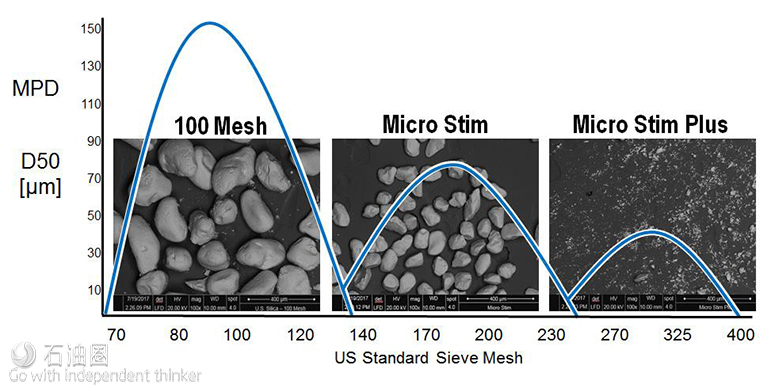

U.S. Silica has developed the Micro Stim proppant product line. Available in two sizes, this new family of microproppants includes the Micro Stim (200 mesh/75 μm) and the Micro Stim Plus (325 mesh/44 μm). For reference, Micro Stim proppant has a target median particle diameter (MPD/D50) that is equivalent to the thickness of a human hair, while Micro Stim Plus proppant has half this MPD with a particle size distribution that reaches into the nanoparticle-range.

These microproppants facilitate the stimulation of the untouched and unrealized secondary fracture network by penetrating these fractures, propping them and providing conductive pathways for increased production. There have been stimulation designs using these microproppants as a lead-in product and Micro Stim as the primary proppant completed across the U.S. For example, in December 2017 the company provided 9 million pounds of Micro Stim proppant for a job in the Marcellus Shale, where it is being utilized as the primary proppant.

Settling rate, proppant transport

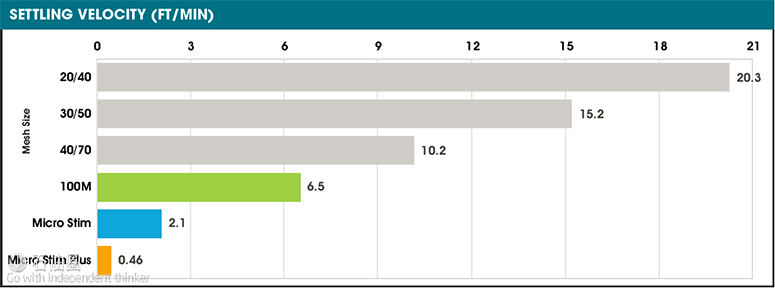

Due to the smaller particle size the Micro Stim proppants will not only access the smaller fracture widths but will have an improved settling velocity rate since settling rate decreases proportionally with a reduction in particle size. Laboratory testing has shown that standard 100-mesh proppant has a settling rate that is three times faster than Micro Stim and 14 times faster than Micro Stim Plus proppants in ordinary tap water. Further amendments to the fluid chemistry will only enhance the inherent reduction in settling rate of these proppants, allowing further penetration in the secondary natural fracture. Because of this dramatic reduction of the settling rate, these microproppants have enhanced proppant transport characteristics. This enhanced mobility allows the proppant to stay suspended in low-viscosity fluid and at low volumetric flow rates. The improved suspension performance allows these microproppants to transverse farther away from the wellbore through the irregular and complex geometry of a secondary fracture as it approaches the fracture tips to increase effective fracture length and thus leave more surface area propped.

Fine details

The Micro Stim proppant is a whole-grain product that can be transferred through typical existing transfer equipment for conventional proppants, similar to 100-mesh proppant. The capability to utilize this equipment allows immediate utilization in the field with no equipment alterations. It is selected from a high-purity silica source (more than 99.5%), which maintains high hardness and enables an inert-like behavior in fracturing fluid compatibility like all other existing silica sands. The company has multiple mine locations across the U.S. capable of producing this material to meet large volume demands with short lead times and access to all major Class 1 railroads.

The Micro Stim Plus proppant is ground silica flour refined from a quality high-silica ore (more than 99.5% silicon dioxide) and sized to specification. The ground silica has been used in recent years as a lead-in proppant in multiple wells, formations and regions. The high-purity silica content will facilitate an inert nature to fluid interaction and formation damage (e.g., clay swelling). The particles are not spherical in shape but do maintain the hardness (7 Mohs) equivalent to conventional silica proppants. This is a distinct advantage compared to other micro/nano-sized particles that do not have an equivalent hardness.

Bulk shipments require specialized equipment and engineering controls to ensure the product will not cake or bridge along with respiratory exposure reduction and mitigation for HSE considerations. Ground silica flour has been used for years in the industry as an additive for cementing and is being used within fracturing applications as well.

The company has seen many changes in the selection and utilization of proppants over the past decade and helped lead proppant innovation over that time period. The development of the Micro Stim proppant family for the stimulation of secondary natural fractures is the next evolution for proppants in the stimulation design. Microproppants could hold the key to vastly increasing effective fracture lengths and SRVs and adding significant value to the well’s financial performance and longevity.

石油圈

石油圈