WELLHEAD DESIGN

When it comes to wellhead installation, time is not only money; it’s rarely on your side. It’s a labor-intensive process in a dangerous environment, where non-productive hours in the rig cellar not only subtract from the bottom line, they put workers and assets in harm’s way.

To address these interdependent challenges, Weir engineered a new type of wellhead to reduce overall non-productive time while enhancing safety. Its Seaboard Unitized Lock-Ring wellhead (ULR) design is the product of a collaborative approach involving a multidisciplinary team of engineers, customers, manufacturing, supply chain, and quality assurance experts.

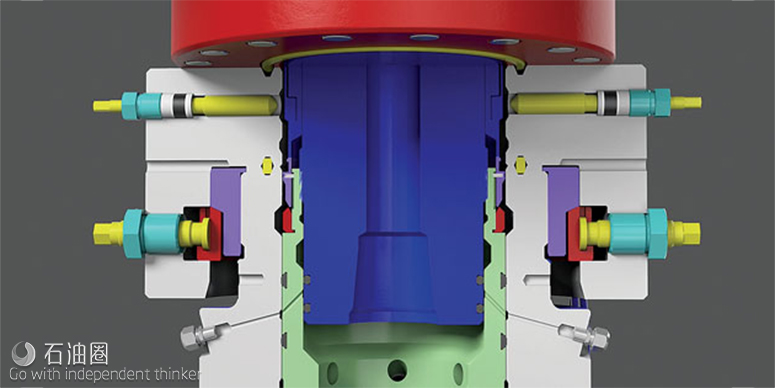

Ultimately, says Weir, the ULR was designed to ease the pressure on an operator’s bottom line, Fig. 1. Collaborating with a diverse team of experts allowed the design process to look beyond traditional variables to deliver a significantly lower cost of ownership.

The expanded team was able to not only address issues of equipment design, but factors such as materials sourcing, which typically don’t figure into the problem-solving process. As a result of leveraging parallel development paths during manufacturing and streamlining logistics, design-to-delivery time was reduced 50%, from six months to about 12 weeks.

The ULR design had to be more compact than the average wellhead to address many traditional wellhead challenges. Creation of a nested system within a single-piece housing resulted in an overall shorter stack-up height and reduced weight that resulted in easier access and lower risk installation, Fig. 2.

Running procedures on traditional wellheads were studied carefully. Normally, BOP removal is required to install the next stage. The BOP is then reconnected, with each flange taking 3 to 4 hr. The process also must wait on cement to set before lifting the BOP off the next wellhead, manually setting slips, and trimming casing to match the next spool. This procedure can take up to 18 hr.

Not only is the typical running procedure time-consuming, it’s a dangerous process involving flame cutting, welding, and grinding in a volatile environment. A key design goal was to simplify installation by eliminating these time-consuming procedures, and their attendant risks and costs.

The ULR’s mandrel casing hangers allow casing to be run, landed, circulated and cemented through the rotary table and BOP with no cutting, welding or grinding required. An internal lock-down seal assembly vastly simplifies the procedure while eliminating the multiple leak paths found on traditional wellheads. Combined, these improvements can save 6 to 8 hr per casing string.

A quick-connect hub lets the operator align, land and secure the BOP on the wellhead, much faster than with a conventional connection, reducing rig-up time from 2 hr to less than 30 min.—with no waiting on cement before resuming operations.

BOP DESIGN

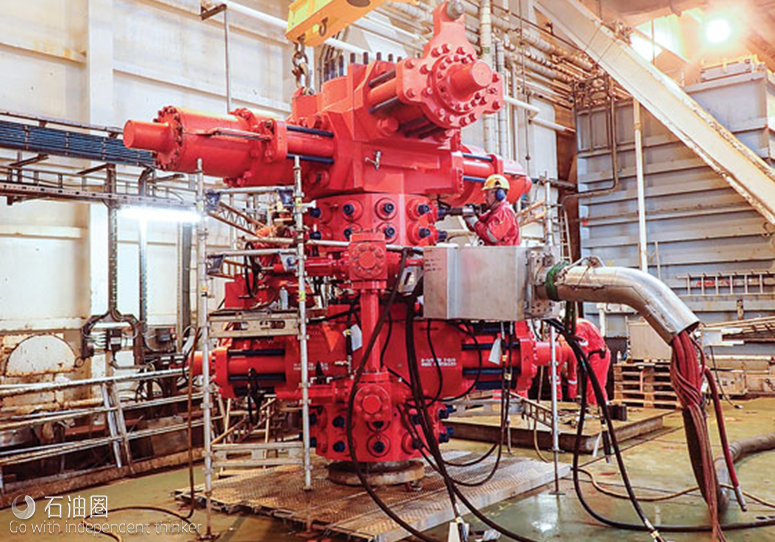

Conventional blowout preventer (BOP) design is challenged on multiple levels. Among them are the growing operational requirements posed by drilling applications, the introduction of new regulations and standards, and marketplace demand for greater cost efficiency. These factors can limit the application, effectiveness and economics of standard BOP technology, says AXON Pressure Products.

The company’s X-TREME BOP design offers an innovative approach to dealing with these issues, Fig. 3. While conventional multi-cavity ram BOPs have just two or more cavities in a linear arrangement, the AXON design arranges ram cavities in a staggered pattern. Staggering the ram cavities arranges them in closer proximity to each other along the wellbore. In double, triple and quad configurations, the unique pattern allows additional shearing rams at little-to-no extra cost versus conventional units.

AXON says the design addresses many conventional BOP limitations. Greater drilling demands and new industry standards, such as requirements for dedicated shears, can result in BOP stacks exceeding the capacity of standard handling equipment. The staggered X-TREME BOP design addresses this with a substantial decrease in height and weight.

The staggered arrangement also allows for simultaneous maintenance on multiple cavities and easier access to internal components. Service life is improved, due to reduced body stress achieved with more supporting materials between cavities, along with decreased bending stresses, due to reduced height.

Shearing safety and performance is improved by the offset cavities, which provide concurrent and/or subsequent activations at alternate angles. The different shearing directions provide guidance for better drill pipe centering.

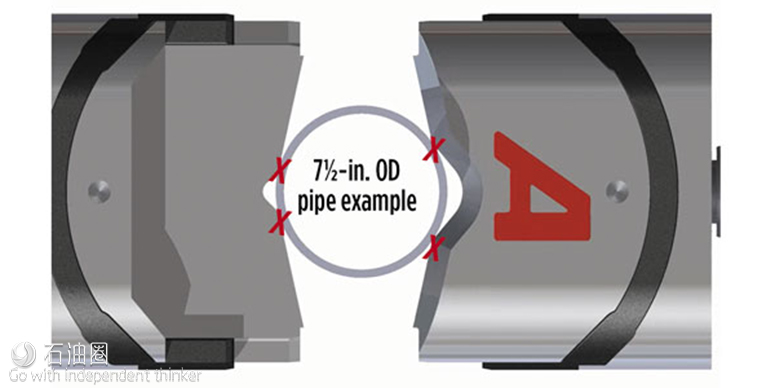

In addition, the new BOP design features four-point-contact V-Shear technology that creates high stress in localized areas to initiate crack propagation and/or pipe shearing at lower operational pressures, Fig. 8. This pipe centering technology produces a higher shear force and lower operating force to enhance shearing on a variety of pipe sizes.

SHALE RIG

Shale well construction costs and operational demands in North America continue to drive land rig design. Long laterals, batch drilling and other shale development practices have resulted in a host of performance demands that impact rig hoisting, rotating and circulating systems. The multi-faceted design response includes innovations aimed at hole cleaning, trip time, penetration rates, and move times, along with more sophisticated data management systems, all in the name of greater efficiencies.

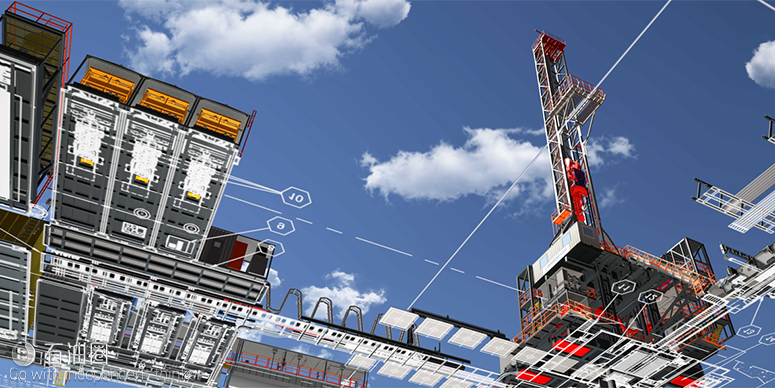

One of the latest and most specific innovations is Drillmec’s Striker-800 design, an ultra-high-spec rig package engineered for shale batch and cluster drilling operations, (see cover image). Drillmec says the design is the first off-the-shelf turnkey shale-drilling package to flexibly integrate all rig components. The modular design allows the drilling contractor to choose the top drive, drawworks, mud pumps, and other drilling equipment from various manufacturers, including Drillmec. This flexibility enables rig specifications to be cost-effectively matched to the existing fleet, as well as specific application requirements. The modular design also provides fast integration of third-party services, such as cement, mud, and waste management.

The “ultra” designation denotes an emphasis on the application analysis that was performed prior to developing and finalizing the package, and the related technological offering. The upfront, shale-oriented analysis resulted in multiple features and specifications aimed at safely reducing rig-up and moving time; improving cluster and batch drilling performance; development of specific data management systems; and enhancing efficiency and reliability within a simple, space-efficient layout.

Rig-up, moving, safety and speed are emphasized with a patent-pending Hydraulic Safe-Lift raising system that enables mast and setback installation at ground level, and erection in a single “one-shot” operation. BOP handling efficiency and safety is enhanced with a fully covered test-stump work area that facilitates offline maintenance and testing for two BOP stacks.

Rig walking during multi-well pad drilling, especially in high-density fields, benefits from several features. A side cellar substructure provides the clearance to walk the rig over existing wellheads and cellars with different spacing, using a multi-directional walking system. Two walking configurations provide versatility in different well cluster grids and allow the rig to cover 150 ft (expandable to 250 ft) in walking distance length and 50 ft in width for a three-cluster well

row configuration.

The built-in rig module is designed to reduce the release-to-spud time between wells. It includes a floor-mounted choke manifold, choke and kill lines, accumulator unit and control lines to minimize BOP and pressure testing time. In addition, the trip tank and treatment tank are onboard to enable real batch drilling capability. The rig can walk with a full set-back, hung BOP, and a treatment tank full of mud to further enable economic batch drilling operations. A hybrid cable management system allows X- and Y-axis skidding without power shutdown.

Standard specifications for the rig include a 137-ft clear height, 800,000-lb static hook load mast on a 32-ft drill floor with a 600,000-lb setback capacity. Hoisting is achieved with a 1,500-hp drawworks, and rotation is provided by a 500-ton high-torque top drive. The high-pressure mud system includes heavy-duty 1,600-hp mud pumps with 7,500-psi working pressure.

石油圈

石油圈