Tracerco has added a fast scanning application to its subsea pipeline inspection instrument, Discovery.

Following customer feedback, Tracerco has completed further R&D work on the unique technology to develop a new method, specifically for detecting the presence of localised metal loss defects on subsea pipelines, up to 5 times faster than before.

The new development for Discovery? means that once a potential anomaly has been identified via the fast scanning method, a more detailed and accurate scan to fully characterise it can be undertaken, simply by extending the duration of the fast scan. This eliminates the requirement of a separate scan and the need to deploy a secondary technology to validate the findings from the initial fast scanning inspection.

Kim Thye Lee at Tracerco stated “By enhancing the capabilities of Discovery?, operators now have the ability to quickly and accurately screen subsea pipelines to determine whether the integrity is within the acceptable tolerance specification. With non-intrusive inspection through any type of protective pipeline coating, defects can be fully characterised faster than ever, without interrupting production. This will enable operators to save on time, resource and ultimately the cost of an inspection campaign”.

The first two inspection campaigns utilising Discovery? as a fast scanning technology have recently been completed on a large diameter export pipeline in the Arabian Gulf and across a range of infield flowlines and jumpers in the Gulf of Mexico. The quality and volume of inspection data obtained, provided our customers with sufficient statistical confidence that the fast scanning results were representative of the condition of their entire system. As such, both customers were extremely satisfied with the results, providing another testament to this impressive technology.

Since the launch in 2013, Discovery? has been deployed across a number of geographic locations, completing thousands of scans and providing operators with real time integrity data to allow them to make critical decisions quickly and with confidence.

Discovery can non-intrusively visualise wall deterioration and the contents of unpiggable coated pipelines without interrupting production. Not only can it provide accurate wall integrity data, it achieves all of this without the need to remove the pipe’s protective coating or cleaning wax build-up. This reduces the risk of corrosion, eliminates the expense of deploying divers, and saves time and money by not stopping production.

Flow Assurance of Subsea Pipelines

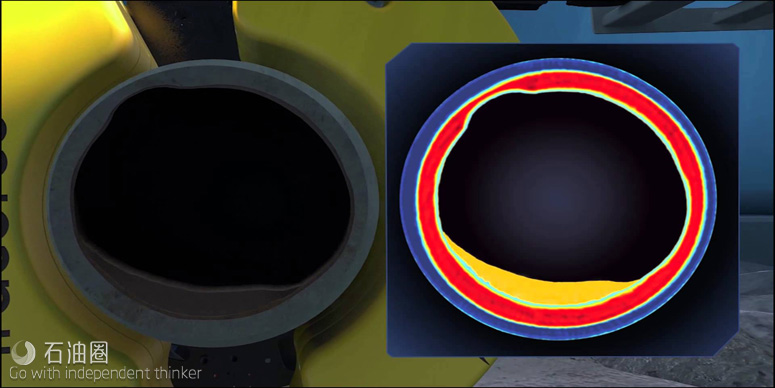

Image showing Discovery’s measurement of hydrate and wax build-up in a coated pipeline

Discovery from Tracerco can determine flow assurance issues in both coated and uncoated, piggable and unpiggable subsea pipelines without interruption to pipeline operations.

Flow assurance specialists can now obtain an accurate measurement of the type of deposit build-up in pipelines, which was previously impossible using any other technology.

Discovery can also diagnose the effectiveness of any remedial treatment. This has several benefits for the operator, including:

Previously unobtainable data can now be obtained on any type of deposit build-up in pipelines to allow the operator to optimise production.

Measurements can be taken online with no interruption to pipeline operations.

There is no risk of a stuck pig.

There is no risk to production as the measurements are taken from the outside of the pipeline.

No need to remove coatings (quickly deployed).

Immediate results.

Can be used for the inspection of unpiggable pipelines.

Non-intrusive detection.

Easily deployed and simple operation through an ROV.

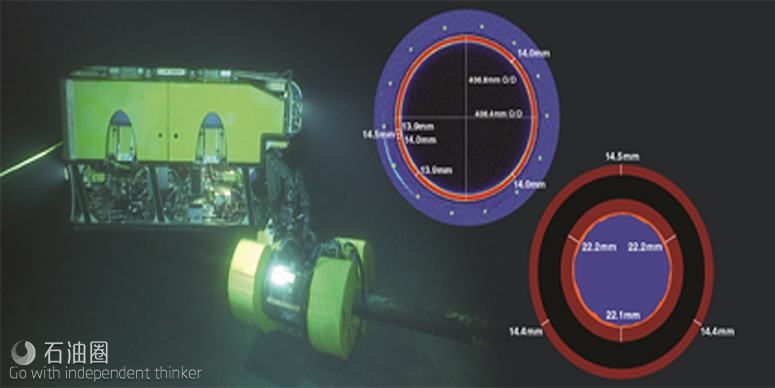

Integrity and Flow Assurance of Subsea Pipe in Pipe Systems

For the first time Discovery provides integrity specialists with a reliable method of diagnosing wall thinning of both pipes in a pipe-in-pipe system.

Integrity and inspection specialists can now obtain data on weaknesses and wall thinning as well as water ingress between pipes, allowing both the inner and outer pipeline in a pipe-in-pipe system to be inspected from the outside.

Image showing computerised visualisation of weaknesses in pipe in pipe subsea systems.

Both pipelines can be assessed for integrity

No need to remove coatings (quickly deployed)

Immediate results

Can be used on unpiggable pipelines

Non-intrusive detection

Easily deployed and simple operation through an ROV

“Instant pipeline visualisation for both inner and outer pipes.”

石油圈

石油圈