Dynamus Extended-Life Drill Bit

Give your horsepower the bit it deserves.

If your bit could perform in the harshest conditions and toughest parameters, you could be:

(1)Drilling one-run, one-BHA intervals

(2)Underspending your AFE

(3)Avoiding unplanned trips

(4)Eliminating after-hours surprises

(5)Setting new benchmarks

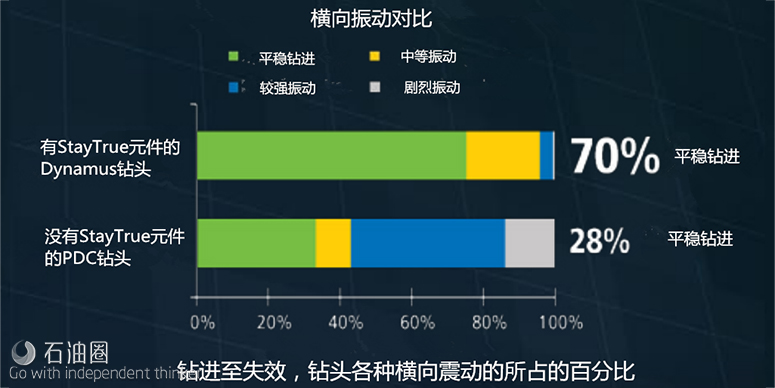

Stable :Dynamus bits incorporate StayTrueTM elements to mitigate the lateral vibrations that reduce wellbore quality.

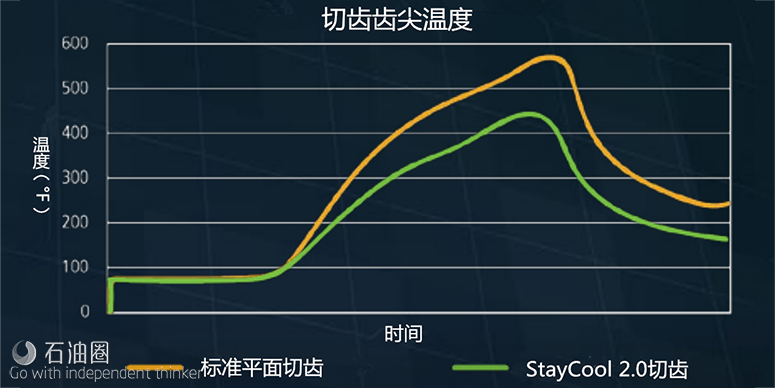

Tough: Dynamus bits use StayCoolTM 2.0 cutter technology to resist wear by lowering the operating temperature of the diamond cutter.

Great New Body:Dynamus bits use enhanced, high-strength materials that resist damage, providing the most durable frame we’ve ever built.

Case Study 1

Dynamus Extended-life Drill Bit with StayTrue Technology Increased ROP 32%

Challenges

(1)Drill vertical intermediate section through interbedded formations with up to a 15° build

(2)Reduce cutting structure damage from lateral vibrations

(3)Increase ROP by preventing frequent slides to correct for deviation

Baker Hughes solution

(1)Dynamus extended-life drill bit

(2)StayTrue shaped diamond element technology

Results

(1)Drilled 6,194 ft – the longest run in the interval

(2)Increased rate of penetration by 32%

An operator working in Midland County, Texas was drilling the 12-1/4-in. vertical intermediate section in the Delaware Basin, but was having some challenges. The interval consists primarily of interbedded formations and high-strength stringers, causing a high degree of impact damage on their drill bits, and necessitating multiple bits to complete the section. Their average ROP was also constrained by erratic directional control, resulting in frequent deviation corrections using only the motor to steer. The operator’s main goal was to drill the entire intermediate section with one bit with and a high rate of penetration (ROP).

Baker Hughes proposed a Dynamus™ extended-life drill bit equipped with StayTrue™ shaped diamond element technology to improve the operator’s ROP and enable them to drill the interval in one run. The Dynamus bit is engineered to be highly robust, enabling operators to drill further and faster in challenging applications. StayTrue elements feature an exclusive chisel-shaped cutting geometry which improves lateral stability and leads to enhanced drilling efficiency and overall durability improvements. The Dynamus bit also included an upgraded bit body material and more robust depth of cut control to enable the operator to meet their overall objectives for the well.

The Dynamus bit drilled 6,194 ft (1888 m) in a single run—further than any previous 12-1/4-in. bit the operator had used in this section. Drilling speed was also improved. The Dynamus bit drilled at an average ROP of 84 ft/hr—32% faster than the best offset.

A dull comparison between the Dynamus bit and a previous bit offering used on the same rig and same pad shows a 70% improvement in dull condition for the Dynamus bit despite the increased footage. The average dull condition for offset bits was 3-4, but the dull condition Dynamus bit was 1-1.

Case Study 2

Dynamus Extended-life Drill Bit Saved 2.3 Days of Drilling Time

Challenges

(1)Complete long, challenging, interbedded lateral in one trip

(2)Minimize damage through hard, interbedded formations

(3)Prevent small wear-flats that cause large degradation in ROP

Baker Hughes solution

(1)Dynamus extended-life drill bit

(2)StayCool 2.0 multidimensional cutter technology

(3)Overload protection elements

Results

(1)Set a new drilling speed record by improving ROP by 95%

(2)Completed 10,500-ft lateral in one trip

(3)Increased footage by 27%

(4)Saved 2.3 days of drilling time

An operator drilling the upper Meramec formation in Blaine County, Oklahoma was having trouble completing the 8-3/4-in. lateral in one run. The lateral formation consists of interbedded siltstone and limestone rock with numerous zones, and the operator also frequently encountered high-strength stringers as well as chert and dolomite. Crossing these zones commonly caused vibrations and bit-damage. Additionally, previous runs demonstrated that even small amounts of wear on the cutting structure of the bit could lead to dramatic decreases in drilling speed, often prompting the operator to trip out for a replacement bit.

Believing it was possible to drill the entire lateral in one run and with increased speed, Baker Hughes recommended the Dynamus extended-life drill bit. The Dynamus bit is engineered to be highly robust, enabling operators to drill further and faster in challenging applications by preventing the damage and dysfunctions that these applications typically cause.

The bit was outfitted with StayCool™ 2.0 multidimensional cutters to reduce wear-rate and cracking tendencies and increase drilling efficiency. The innovative geometry on the face of the StayCool 2.0 cutters reduces the temperature at the working surface, preserving cutter life and enabling longer runs at higher ROPs.

The Dynamus bit with StayCool 2.0 cutters completed the 10,500-ft (3200 m) lateral section in one run, increasing footage by 2,500 ft (762 m) compared to the standard PDC offset—a 27% improvement. Drilling speed was also significantly improved—the Dynamus bit drilled the section with an average ROP of 102.5 ft/hr—95% faster than the highest-performing offsets, setting a new drilling speed record for the application. In addition, when it was pulled from the hole, the Dynamus bit was dull-graded at a 1-1, demonstrating its longevity. Even after drilling more than 10,000 ft, the Dynamus bit with StayCool 2.0 cutters had almost no wear or damage.

石油圈

石油圈