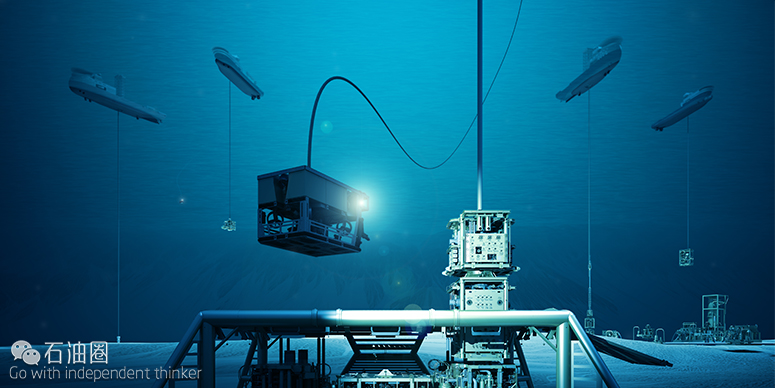

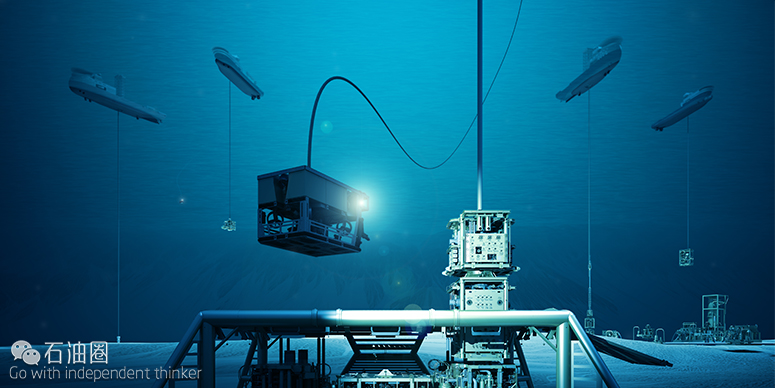

LankoDeep 软绳系统是石油行业与材料行业联合合作的一次成功项目,该软绳系统可以在超过3000米的水深处承受重载荷,可谓是深海服役设备的良伴。

软绳系统是Lankhorst Ropes公司、Deep Trek公司与DSM Dyneema公司合作开发的。该绳索系统可以在超过3000m水深处承受重载荷,包含了Lankhorst Ropse公司的Lanko®深水绳索技术,DSM的Dyneema(高强度、高弹性的光纤)技术以及Deep Tek的主动升沉补偿(AHC)滚筒绞车系统。

Lankhorst Ropes公司研发的Lanko®Deep AHC 是新型软绳系统的有机组成部分,能够在超过三公里的水深处承受高强度载荷。Lanko®deep 的成功研发得益于研发团队的敬业奉献以及与DSM Dyneema的精诚合作,该技术具有最佳的深水抗滑轮循环弯曲(CBOS)疲劳性能和承重特性,特别适用于深海服役的系统。

Lanko®Deep 技术的研发是基于Dyneema® DM20 XBO合成纤维长丝技术,并采用了绳索涂层专利技术,以保证其抗循环弯曲性能优异。Lankhorst Ropes 大型起重设备销售经理Sérgio Leite 表示:“该新型绳索共由12股编成,每股又都是由三股绳构成,这种结构再于DM20 XBO涂层结合使用,可以帮助减少固定绳索时所需的拉力,以及绳索内部的发热和摩擦。此外,运营商还可以对绳子进行检查和维修,对于深水应用来说,毫无疑问,这是一项革新性的技术。”

软绳系统中另一个重要组成部分是Deep Trek 的滚筒绞车,包括了多层V型绕线机。这项具有创新性设计的滚筒绞车系统可以安装在海上起重机上,方便操作。

软绳系统的设计和整合都是以功能性为导向进行的,所参考的基本标准原则来自DNV GL海上标准,DNV-OS-E407深水部署和回收系统,DNVGL技术资格推荐操作,DNV-RP-A203新技术资格认证程序。

新型的滚筒绞车设计允许软绳在其上的绕线形式,保证了多层纤维绳索在绞车卷筒上处于承重状态时不会有被切断的风险。这一点已经得到了DNV-GL的认证,在空气中可承受的有效转矩100Te,3000米水深中可承受的有效转矩110Te。在空气和水中分别可承受165TE和275TE的性能更优的软绳系统也正在开发中,不久即可面世。

销售经理Sérgio Leite 表示:“Lankhorst Ropse拥有悠久绳索创新历史,能够在海洋勘探领域获得创新奖对于Lankhorst来说是一项重大的成就。油气行业对我们表示出了在钢丝绳索的研发上进行深度合作的意愿,而我们当时最大的挑战在于提供一种可以在超过3000米水深的环境中工作的合成绳索。”

与自重较大的钢丝绳相比, Lanko®Deep的3股纤维绳结构自身即可浮在水面上,并可在负载能力和弯曲柔韧度之间实现最佳平衡。由于其交叉点数量达到最少,减少了内部摩擦的几率,摩擦损坏几率降低,绳索的开放式结构尤其便于拼接、截断和修复。石油圈原创www.oilsns.com

除此之外,绳索所采用的特殊Dyneema纤维,可以减少固定绳索时所需的张力,以及内部的发热和摩擦情况。

如需获取关于该技术的更多资料,请联系石油圈技术运营 惊蛰,QQ:2582825239。

来自/Lankhorst ropes 译者/周诗雨 编辑/Lemon

The Soft Rope System is a collaboration between Lankhorst Ropes, Deep Tek, and DSM Dyneema. It’s capable of handling heavy loads at water depths of well over 3,000m. The system comprises Lankhorst Ropes’ Lanko®Deep rope, DSM Dyneema, and an Active Heave Compensation (AHC) drum winch system from Deep Tek.

Lankhorst Ropes has announced Lanko®Deep AHC; the rope is an integral part of a new Soft Rope system capable of handling heavy loads at depths of well over three kilometres.

Through its dedicated research and development teams and co-operation with DSM Dyneema, Lankhorst has developed Lanko®deep AHC (Active Heave Compensation) rope, which incorporates fully optimised cyclic bending over sheave (CBOS) fatigue and load bearing characteristics for use in the deepwater deployment systems.

Lanko®Deep AHC is based on Dyneema® DM20 XBO synthetic filament optimised for cyclic bending with a proprietary rope coating technology. “The new rope has 12 stranded braids where each strand is a three-strand rope,” explains Sérgio Leite, Sales Director, Heavy Lift, Lankhorst Ropes. “This construction, combined with the DM20’s XBO coating, helps reduce the tension required to bed-in the rope, as well as reducing internal heating and abrasion. In addition, the rope can be inspected and is also repairable, it is an innovative solution for deepwater deployment.”

The other element of the Soft Rope system is a Deep Tek Drum Winch with multi-layer chevron spooling. This revolutionary drum winch system can be installed in offshore cranes.

The design and integration of the Soft Rope system is entirely function-based, in accordance with the underlying principles of DNVGL Offshore standard, DNV-OS-E407, Underwater Deployment & Recovery Systems and DNVGL Recommended Practice for Technology Qualification, DNV-RP-A203, Qualification Procedures for New Technology.

The innovative patented drum winch design ensures a spooling pattern that allows multiple layers of fibre rope to be spooled onto a load bearing winch drum with no risk of cutting in. It is certified by DNV-GL at 110Te in air and 110Te at 3,000m water depth. Larger Soft Rope systems capable of handling 165Te and 275Te are in development.

The design and integration of the Soft Rope system is entirely function-based, in accordance with the underlying principles of DNVGL Offshore standard, DNV-OS-E407, Underwater Deployment & Recovery Systems and DNVGL Recommended Practice for Technology Qualification, DNV-RP-A203, Qualification Procedures for New Technology.

Sérgio Leite, Sales Director, Lankhorst Ropes Offshore commented “ Lankhorst Ropes has a long history of rope innovation. To be part of another award winning innovation is a great achievement for Lankhorst. As the Oil & Gas industry had shown the desire to work at greater depths than possible with steel wire ropes, the challenge was to provide a synthetic rope that could. Lankhorst’s Lanko®Deep AHC rope makes operating at over 3,000m possible”.

Lanko®Deep

The 3-strand fibre rope is neutrally buoyant in water compared with the far higher, self-weight of steel wire rope and provides the optimal balance of load-bearing capacity and flexibility of bending over sheave.

The innovative Lanko®Deep AHC design ensures the minimal number of cross-over points and thus reduces the opportunity for internal abrasion. The open structure of the rope makes it especially easy to splice, inspect and repair. In addition, the rope’s special Dyneema fibre grade reduces the tension required for bedding in the rope, as well as reducing internal heating and abrasion.

未经允许,不得转载本站任何文章:

-

- Demons

-

石油圈认证作者

- 毕业于中国石油大学(北京),化学工程与技术硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系Demons(QQ2582825239;微信15810965891)

石油圈

石油圈