SPACE® Vernier

SPACE® Vernier is a state-of-the-art high-resolution cased-hole ultrasound thickness and caliper tool. Using the established technology applied in medical ultrasound imaging, SPACE® is designed and built for the hostile environments encountered downhole. The tool is capable of measuring the internal diameter and wall thickness of tubing or casing in most production fluids. Proprietary software allows detailed mapping and visualisation of the tubing or casing, as well as statistical analysis of corrosion and damage.

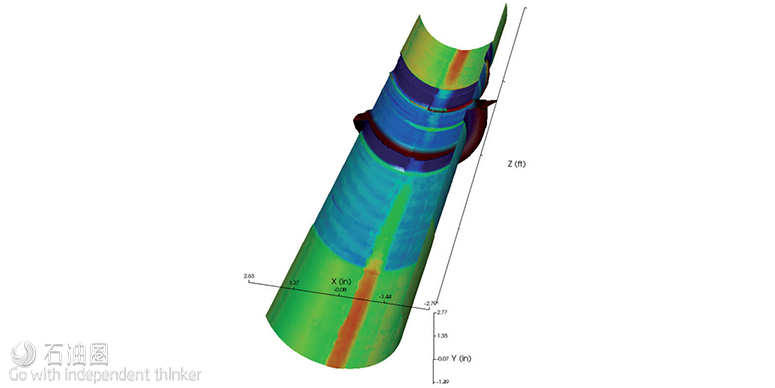

Visualise your well in 3 dimensions

STAVANGER — Archer, the global oilfield services company, has launched a new generation of SPACE ultrasound imaging and measurement services, which apply ground-breaking ultrasonic techniques – such as phased-array beam-forming – to enable true spatial understanding of the downhole environment.

The launch introduces SPACE Vernier, a service designed to maximize well life by measuring the internal and external dimensions of the entire wellbore to generate statistical analysis of localized damage and systemic corrosion. The technology features a unique no contact design, which eliminates the risk of damage to the well tubing.

Benefits

—High accuracy measurements of pipe internal diameter

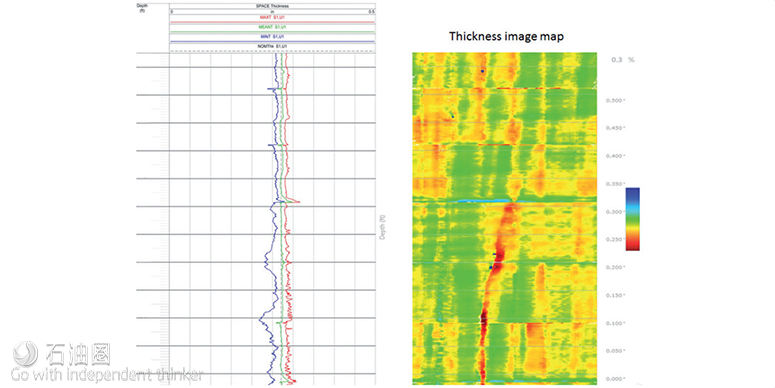

—Direct measurement of wall thickness, at up to 288 points circumferentially

—Operates on adaptive high-speed telemetry system

Applications

—Tubing and casing measurement and analysis—internal diameter and wall thickness

—Tubular inspection—detection of corrosion, damage and deformation

—General imaging applications with extended features unavailable to optical cameras

Real time understanding

Logging is performed dynamically with detailed 2D measurement of the inner and outer surfaces. Both the number of transducer elements used and the vertical resolution of the sampling may be adjusted to

allow a quick scan or a more detailed inspection. Our proprietary software enables the creation of thickness and diameter plots as well as 3D images.

A circumferential multi- element transducer array is coupled with electronic focusing to optimise the ultrasound

beam for different pipe diameters. The transducer array of 288 elements operates in pulse echo mode, with the time of flight of the reflected echoes from the internal and external pipe

surfaces providing both inner diameter and wall thickness. Multiple different sizes of tubular (e.g. production casing and tubing) can be logged in a single run in hole. A speed of sound sensor provides real-time calibration, ensuring accuracy.

Specifications – SPACE® Vernier

Physical

Outer diameter:3” [76 mm]

Length:52.8” [134.1 cm]

Weight:49.2 lb [22.3 kg]

Environmental

Maximum temperature:239°F [115°C]

Maximum pressure:7,500 psi [517 bar]

Electrical

Voltage:240 VDC

Current:200 mA

Functional

Number of sensors:288

Maximum azimuthal resolution:1.25 deg

Vertical resolution:0.39” [10 mm]

Precision–ID:± 0.012” [0.3 mm]

Precision–Thickness:± 0.012” [0.3 mm]

Measurement range–Thickness:0.2-0.8” [5-21 mm]

Measurement range–ID:4-13” [102-330 mm]

Operational

Logging speed:3-30 ft/min [0.9-9.1 m/min]

Logging mode:Real-time

Well conditions

Fluid:Water, brine, oil, produced liquids

Minimum casing ID:4-1/2” [114 mm]

Maximum casing size:13-3/8” [340 mm]

石油圈

石油圈