To describe Saipem’s in-development Hydrone technology, Paolo Bonel starts with a declaration meant to clear up any misconceptions.

“This is not an AUV,” says Bonel, manager of remote control systems in Saipem’s Sonsub division, using the common abbreviation for autonomous underwater vehicle.

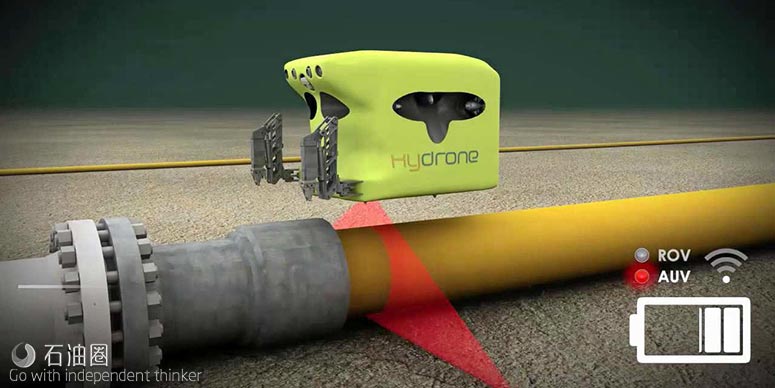

It is, rather, more an autonomous remotely operated vehicle (ROV), sometimes tethered, sometimes freeswimming, capable of the usual subsea inspection tasks but also able to perform autonomous light intervention as necessary.

“What we’re doing with the Hydrone is moving the brain on board the ROV — not only the eyes and hands, but also the brain,” he says.

A true hybrid ROV/AUV has been on the industry’s wishlist for years. The downturn has only increased interest, as oil companies seek ways to reduce the cost of operating and maintaining subsea installations.

There are a number of research and development programmes under way, with somewhat different goals in mind. Saab Seaeye’s Sabertooth hybrid inspection vehicle (Upstream Technology 1/2017) features subsea docking and the ability to perform some maintenance and repair tasks.

The Flatfish AUV programme, involving BG Group and researchers in Germany and Brazil, is working on a resident subsea inspection robot (Upstream Technology 1/2016).

Subsea 7’s AIV (autonomous inspection vehicle), which has completed field trials with Shell, will operate from a platform or support vessel without a tether. The company plans to increase sensor capacity and light intervention capabilities in future versions of the AIV.

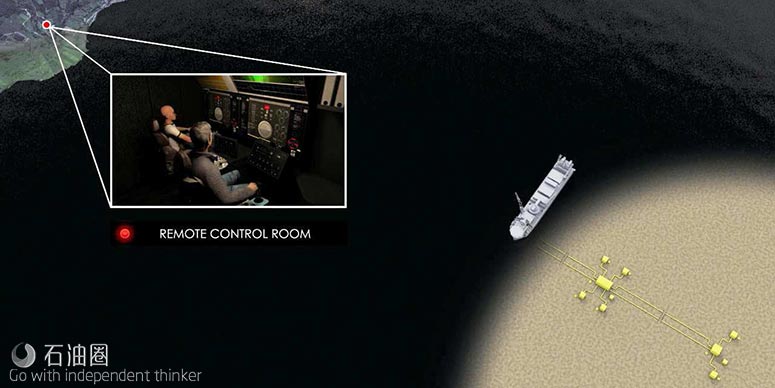

The various programmes share some common goals, driven by increasing industry demand for subsea technologies that reduce reliance on offshore support vessels and enable more remote operations. The Hydrone platform aims to address both challenges, says Bonel.

“It is considered to be resident on a subsea installation — a subsea factory or complex subsea installation,” he says.

“Having something that can intervene in an autonomous way will save the cost of a vessel, for sure, but also will lower the downtime of the subsea facility because Hydrone can intervene in a prompt way.

“It can also reduce risk to the environment. If there is a failure” — a leaking jumper, for example — “this machine, because it is already on site, can automatically intervene and mitigate the environmental risk.”

The Hydrone will operate both with a tether, in ROV mode, or independently, depending on the task. The tether will use magnetic induction connectors for subsea decoupling and connecting.

The robot will be operated with what Bonel describes as “underwater wireless connection”, an evolving technology based on optical and acoustical communication.

Hydrone “has wireless capability”, he says. “What we are going to realise is ‘real subsea wi-fi’ capable to allow data link and video streaming.

“Optical, acoustic and electromagnetic technologies are there, and are complementary,” Bonel continues. “So when one is not working you can use another one. We are developing a multi-mode modem that is able to manage these three physical communication systems and to automatically switch, or distribute the data, through these three different physical channels so that you have a more reliable connection and more bandwidth in the communication.”

Sonsub, located in the Marghera suburb of Venice in Italy, is collaborating with subsea modem manufacturers and academic scientists to develop the technology, he says. The company aims to test a prototype of the Hydrone in 2018.

Saipem last year completed sea trials of its Innovator 2.0, the newest in its line of Sonsub work-class ROVs.

Sonsub vice president Massimo Fontolan says: “We were, and are, still convinced that ROVs are the end effectors of any subsea construction vessel, where performance to a great extent relies on ROV robustness and reliability.”

Hybrid technology could come to play an equally important role in subsea installations.

Hydrone, “in a fashion consistent with our vision as to the future of subsea development”, Fontolan notes, “will be located on the seabed to perform all intervention tasks not requiring a vessel, thus achieving a great operational cost saving, increasing the efficiency of field production and the feasibility of the investment case”.

Saipem plans to produce three versions of the hybrid — Hydrone-S for advanced survey work, a resident model, Hydrone-R, and Hydrone-W, “which you can think of a standard ROV that is supplied by batteries and operated from shore”, Bonel says. “We are developing these technologies here in Marghera. We will be able to use them in different incarnations of the Hydrone, but we can also bring these technologies to the Innovator.”

AUV-ROV hybrids offer operators flexibility, he says: “You can think of Hydrone as an AUV if you are only doing surveys. And you can think of it as an evolution of the ROV.”

Those involved in the project are thinking of the R&D opportunities it presents.

“For us, this is a technological platform,” Bonel says. “We will develop technology for (subsea battery recharging). We will develop technologies for autonomous systems underwater.

“We will develop technologies for electrical manipulators that will last for years under water. And all of these technologies will be combined in different incarnations of the Hydrone.”

石油圈

石油圈