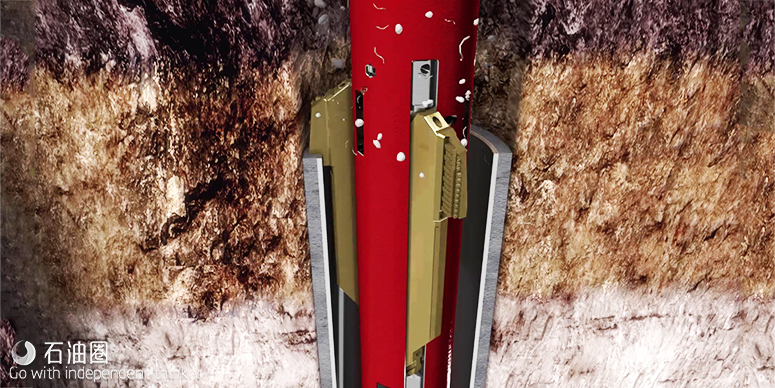

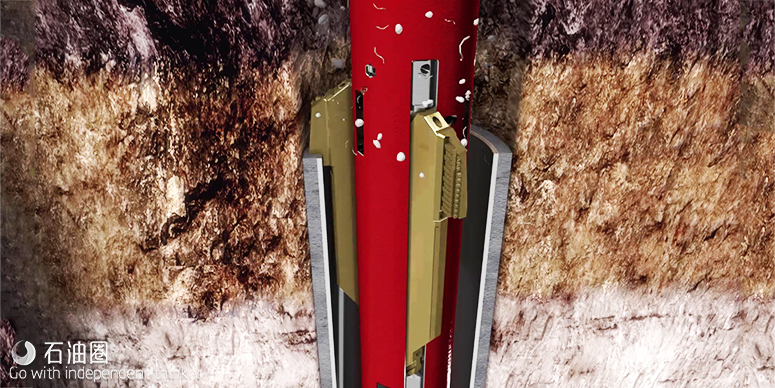

Endura双管串锻铣工具(DSSM)能有效地将井眼中的基岩暴露出来,以获得更好的水泥与地层胶结。

来自 | 威德福

编译 | 覃乐

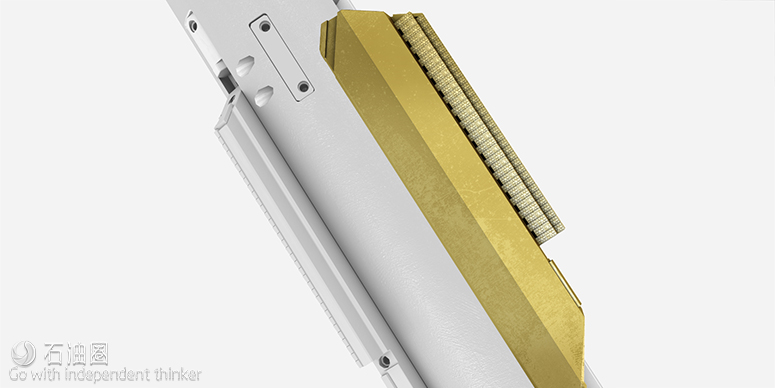

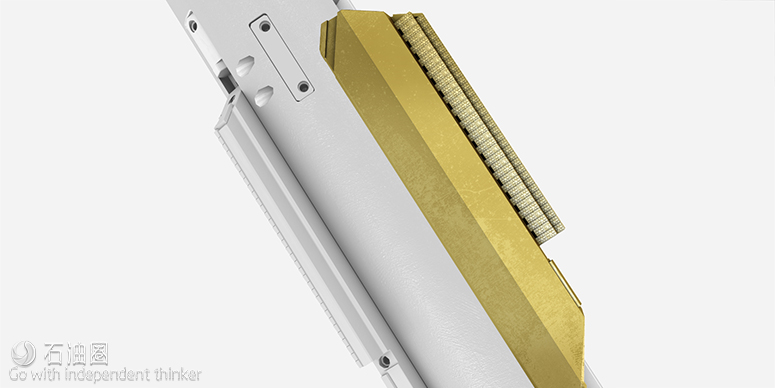

通常情况下,为防止碳氢化合物在封堵井和弃井内迁移最有效的方法是创造一个岩石到岩石、水泥对地层的胶结。Weatherford Endura双管串锻铣工具(DSSM)使用了专门设计的刀片和稳定器,通过对相邻套管串套管的磨铣,快速而有效地穿透井眼,以达到上述目的。单独的磨铣和扶正刀片在提供双扶正作用的同时,能够产生更细、更易于处理的切削。

工具描述

来自Weatherford公司的Endura DSSM能够磨铣外径7in到9 5/8in和13 5/8in(244至346mm)的内外套管串。其配备的两个稳定器——液压、膨胀式稳定器和集成式稳定器,可以确保最佳的磨铣表现。

在用标准锻铣工具将部分内层套管去掉后,DSSM细长的8 1/4in(210mm)外尺寸能使磨铣刀片通过内管串进入外部。位于DSSM底部的一个液压、膨胀式稳定器通过膨胀使该工具居中于外套管串内以阻止其侧向移动。然后切割刀片随着内置整体式稳定器张开,并开始磨铣工序。最后再由17in (432-mm)全尺寸磨铣刀片磨铣较长套管段。

通过彻底去除套管,磨铣段能为永久裸眼水泥塞提供井眼条件。在这种情况下,DSSM较小的外尺寸能够帮助解决与封堵弃井(P&A)锻铣相关的常规问题,同时有助于履行一些弃井施工需满足的最严格的监管要求。

磨铣刀片

应用

(1)任何环境下的封堵弃井施工;

(2)磨铣7in到9 5/8in和13 5/8in(244- to 346-mm)的套管串。

特点和优势

(1)Endura双管串锻铣工具(DSSM)能通过磨铣内外套管串提高封堵弃井(P&A)施工效率;

(2)DSSM拥有双稳定器以确保最佳的磨铣表现;

(3)其磨铣距离能为水泥塞封堵提供有效井眼条件;

(4)DSSM有助于履行一些弃井施工需满足的最严格的监管要求。

参数规格

扣型:4-1/2 IF /NC 50

工具外径:8-1/4 in. (210 mm)

工具内径:2-1/4 in. (57 mm)

工具长度:19-1/2 in. (495 mm)

本体额定扭矩:38,000 ft/lb (51,521 N∙m)

铣刀额定扭矩:15,000 ft/lb (20,337 N∙m)

最大磨铣范围:14-1/2 in. (368 mm)

磨铣套管尺寸:9-5/8 to 13-5/8 in. (244 to 346 mm)

磨铣和封堵流程

(1)在9 5/8-in套管上开窗以后,稳定器在外层13 3/8in套管内张开。

(2)切削刀片将13 3/8in套管割穿,为磨铣做准备。

(3)17in的磨铣刀片(0.43m)磨铣100英尺(30m米)的剩余部分。

(4)固井形成有效的水泥对地层的胶结。

实用案例

Endura双管串锻铣工具(DSSM)第一次用于海上作业,提供裸眼水泥塞封堵,不仅为客户节省了钻井时间,还节约了188万美元。

目标

(1)甲方在9 5/8in和13 3/8in套管环空回填水泥失败后,释放环空压力;

(2)最大限度减少磨铣起下钻次数,施工时间及花费;

(3)创建一个干净的窗口以容纳切割组件;

(4)去除13 3/8-in部分套管,为水泥封堵提供空间;

(5)严格遵守行业P&A(封堵弃井)规定。

解决方案

(1)使用A-1锻铣工具去除9 5/8in套管115ft(35m)长度,以形成一个清洁的可用窗口;

(2)首次下入Weatherford Endura双管串锻铣工具(DSSM),下至设计深度并成功完成切管施工;

(3)磨铣刀片入井,去除98ft(30米)的13 3/8in套管,使操作者能够在甲方最严格的监管要求下,进行裸眼水泥塞施工。

效果

(1)一次起下钻作业就能创建了一个干净的窗口,节省了大量钻井时间并实现了割管作业;

(2)9 5/8in和13 3/8in部分套管被去除,为裸眼水泥塞提供空间以释放环空压力;

(3)使用Endura锻铣工具为甲方节省钻井时间4.9天、节约180万美元,并通过减少须磨铣的套管量来最大限度地减少作业风险;

(4)该施工在甲方严格的P&A管理规定下成功完成。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

二丫:131-3255-0596;zhanglingyu@fonchan.com

大安:131-3203-1392;lishian@fonchan.com

For English, Please click here (展开/收缩)

Endura® Dual-String Section Mill

Mills inner and outer casing strings in plug-and-abandonment (P&A) operations

The most effective way to prevent hydrocarbon migration in wells that have been plugged and abandoned is to create a rock-to-rock, cement-to-formation bond. The Weatherford Endura dual-string section mill (DSSM) accomplishes this with the use of specially designed blades and stabilizers that enable through-casing milling of the adjacent string of casing to access the borehole quickly and efficiently. Separate milling and stabilizer blades provide two points of stabilization while creating finer, more manageable cuttings.

Tool Description

The Weatherford Endura DSSM mills inner and outer casing strings with diameters from 7″ to 9-5/8″ and 13-5/8 in. (244 to 346 mm). The DSSM includes two points of stabilization for optimal milling performance: a hydraulic, expandable stabilizer and an integral stabilizer.

After the section of inner casing is removed with the standard section mill, the slim OD of the DSSM enables the mill to return through this inner casing to the open section. The hydraulic, expandable stabilizer—located on the bottom stage of the DSSM—brings the tool to the center of the outer casing string and prevents lateral movement by expanding to the inside diameter (ID) of the outer casing. The cutting blades then expand with the built-in integral stabilizer to begin the milling process. The 17-in. (432-mm), full-gauge milling blades enable milling long casing sections.

By completely removing casing, the milling run prepares wellbores for permanent rock-to-rock cement plugging. In doing so, the DSSM helps to address common problems associated with section milling in P&A operations and to fulfill some of the most stringent regulatory requirements for well abandonment.

Applications

P&A operations in any environment

Milling 7″ to 9-5/8″ and 13 5/8-in. (244- to 346-mm) casing strings

Features and Benefits

The Endura dual-string section mill (DSSM) enhances the efficiency of P&A operations by milling both inner and outer casing strings.

The DSSM has two stabilizers for optimal milling performance.

The milling run efficiently prepares wellbores for cement plugging.

The DSSM helps to fulfill some of the most stringent regulatory requirements for well abandonment.

STAGES OF MILLING AND PLUGGING

1.After cutting a window in the 9 5/8-in. casing, the stabilizer expands inside the 13 3/8-in. casing.

2.Cutting blades cut a window through the 13 3/8-in. casing to prepare for the milling blades.

3. The 17-in. (0.43-m) milling blades mill the remainder of the 100-ft (30-m) section.

4. Cementing forms a competent cement-to-formation bond.

Endura® Dual-String Section Mill Deployed Offshore for First Time to Provide Rock-to-Rock Cement Barrier, Saves $1.88 Million in Rig Time

Objectives

Relieve pressure on two annuli, where a top-up cement job between the 9 5/8-in. and 13 3/8-in. casing annulus was performed without success by the operator.

Minimize milling trips and operational time and expense.

Create a clean window to deploy cut out assembly.

Remove section of 13 3/8-in. casing to enable a cement barrier installation.

Adhere to strict industry P&A regulations.

Our Approach

An A-1 section mill was used to remove a 115-ft (35-m) section of 9 5/8‐in. casing, facilitating a clean, usable window.

The Weatherford Endura dual-string section mill (DSSM) was deployed for the first time, reaching TD and performing the cut out successfully.

A milling-blade tool was run in hole, removing 98 ft (30 m) of 13 3/8-in. casing, enabling the operator to install a rock-to-rock cement barrier within the operator’s stringent P&A regulations.

Value to Client

•A clean window was created in a single trip, saving significant rig time and enabling the cut out operation to be performed.

•The 9 5/8-in. and 13 3/8-in. casing sections were removed, allowing the cement barrier to be installed to relieve pressure on the annuli.

•The use of the Endura section mill saved the operator 4.9 days of rig time valued at US $1.8 million, and minimized operational risk by reducing the amount of casing that had to be milled.

•The operation was performed successfully within the operator’s strict P&A regulations

未经允许,不得转载本站任何文章:

石油圈

石油圈