Ascend™ Surfactant Solutions

Ascend™ surfactant solutions provides a customizable, dual-component surfactant package which can travel further into the formation than conventional surfactants to access additional trapped hydrocarbon. Along with Multi-Chem’s advanced surfactant technology, Ascend surfactants incorporates a secondary component which is attracted and adsorbed to the rock surface first, often in the near wellbore region, thereby allowing the surfactant to continue traveling with the fracturing fluid into the fracture network where it is needed most.

Features

Custom-tailored surfactant chemistry designed to optimize production from your specific reservoir source rock

Optimal interaction with broader API gravity range of oils to increase mobility through reservoirs

Thermally stable to 350°F (177ºC) for use in a wide range of reservoirs

Proven compatibility with all major gel systems and friction reducers

Benefits

Multi-functional surfactant blends

Minimized surfactant loss (reduced adsorption near the wellbore region)

Enhanced contact area between fracturing fluids and formation reservoir

Significant wettability alteration

Enhanced oil recovery with reduced chemical cost

Yields higher initial production and greater estimated ultimate recovery

Optimized usage rates minimize costs and maximize returns

Enables use of produced water rather than fresh water in fracturing operations

Increased fluid mobility improves lift efficiency, extending pump life

ASCEND PROPRIETARY BLEND OF SURFACTANTS HELPS BOOST WOLFCAMP WELL PRODUCTIVITY.

CHALLENGE

» Stimulate production of unconventional wells with carbonate and clay-rich formation rock

» Avoid trapping of surfactant on rock surface near the wellbore

SOLUTION

Use Halliburton’s customized Ascend™ surfactant with ratio and concentration based on:

» Core cuttings analysis

» Well fluid analysis

RESULT

» Enabled surfactant to further penetrate the rock matrix

» Improved initial production of up to 40-50% compared to offset wells with alternate or no surfactant

OVERVIEW

A major operator was drilling unconventional wells in the Wolfcamp Shale play in Reagan County, Texas where hydraulic fracturing is required to enhance oil and gas recovery. Fracturing fluids utilized in hydraulic fracturing treatments often incorporate surfactant chemistry in order to lower surface tension and capillary pressure so that potentially trapped hydrocarbons can be more readily produced to surface.

In addition to low permeability/high temperature conditions typically encountered, the area of interest was also characterized by rich carbonate and clay formations further complicating the fracturing process. On

such types of rock, traditional surfactant chemistry tends to be adsorbed, sometimes as much as 99%, before it can travel the full length of the fracture. The client’s main goal

was to increase the contact area between the fracturing fluid and the fractured rock surface, and ultimately maximize reserves recovery.

CHEMICAL ENGINEERING SERVICES

Multi-Chem, a Halliburton service, provided chemical engineering expertise to design a solution to ensure the surfactant would reach all the way into the reservoir. The PowderPerm patented procedure was performed on formation cuttings and reservoir liquids which allowed Multi-Chem to optimize the concentration ratio of the primary surfactant and a secondary component into a customized blend.

Initially, a 30-day field trial was conducted on a two-well pad in the Permian Basin. The recommended Ascend™ surfactant package was applied to test the secondary component’s ability to coat the rock surface first, likely in the near wellbore region, and allow the primary surfactant to penetrate further into the formation. Multi-Chem engineers worked in close collaboration with the customer at the wellsite, delivering the surfactant, setting up micromotion pumps, and monitoring and measuring flow rate into the blending equipment.

LEADING EDGE SURFACTANT

The field trial demonstrated little to no surfactant adsorption, with the customized chemical blend allowing the surfactant to travel at the leading edge of the fracturing fluid. During this period, oil and gas production appeared to be significantly higher than the average production from offset wells previously fractured using surfactant without the secondary component. The secondary component in the Ascend surfactant package allowed Multi-Chem’s RockOn® surfactant to penetrate further into the rock matrix and enable production of otherwise trapped fluids.

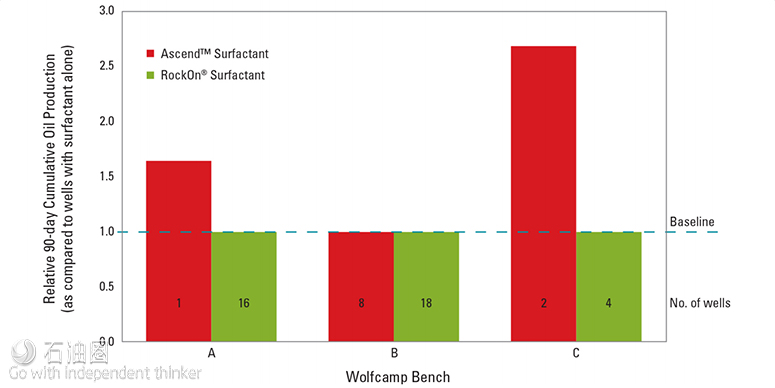

The trial wells showed an increase in daily production of up to 500 BOE per day compared to offset wells with alternate or no surfactant. In the first 20 days, cumulative BOE production was increased by 184% compared to offset wells allowing for recuperation of surfactant investment in less than two weeks’ time. After 90 days producing, cumulative oil production in Wolfcamp A and C wells using the Ascend surfactant package was 1.6 and 2.7 times higher, respectively, as compared to wells using surfactant alone.

石油圈

石油圈