Aspects of the oil and gas industry can be made to sound quite mundane. But at its core the industry revolves around risking insane amounts of money in the hopes of finding hidden treasure.

But oil companies aren’t ruthless pirates. These treasure hunters try very hard to reduce risk at every step of the journey. And lately new software tools are helping them in their quest.

The Big Loop

A case in point is the Roxar RMS reservoir modeling tool from Emerson Automation Solutions, which, when used with the Roxar Tempest ENABLE uncertainty management software, helps reduce risk by enabling multidisciplinary collaboration. The company calls this “Big Loop.”

A key issue with reservoir modeling is the fact that multiple disciplines are involved. Emerson teamed with Statoil in 2012 to form a “Total Uncertainty Management” program focused on how E&P companies can improve history matching, uncertainty management and quantification across the entire reservoir characterization workflow. According to a press release issued earlier this year, Statoil provided “deep technical input” to further the development of Big Loop.

Arne Skorstad, technical product manager for Roxar Software Solutions at Emerson, said there are numerous benefits for both parties as a result of this partnership. “Based on the shared understanding of the importance of the automated workflow’s transparency, auditability and reproducibility, Emerson will get access to real examples from a client’s practical usage of the workflow, from analyzing the seismic data through structural modeling, automatic gridding and property modeling to actual production to analyze where it is most beneficial to improve our software,” he said. “This will be on different levels, like ease of use and speed, both on execution and manual setup, where the amount of clicks should always be subject to reduction. It’s important that the manual work is used on setting up the automated tasks and not on subjective, nonreproducible tasks that will need to be changed for every new datapoint that is brought into the modeling chain.”

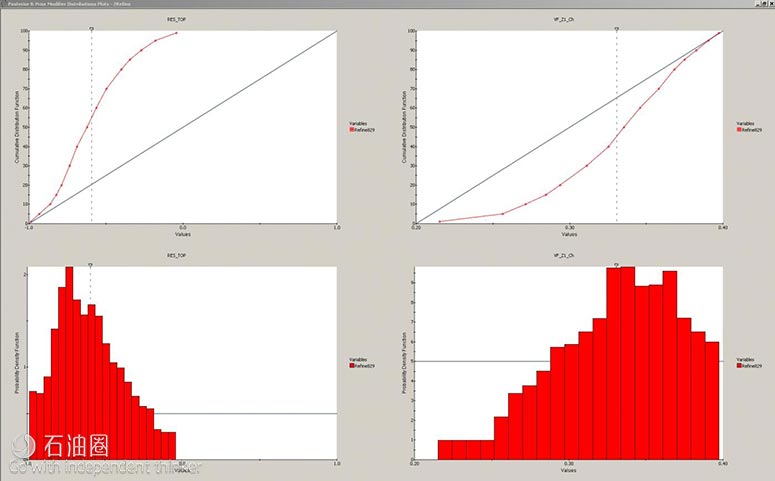

He added that Big Loop helps operators overcome the sequential nature as well as the limitations on updates typical of standard workflows. “It gives operators the ability to include all uncertainties involved and to propagate them all the way into a realistic total uncertainty estimation where dependencies have been accounted for,” he said. “A typical example is structural uncertainty. The seismic data do not uniquely define the structural model for a reservoir, so disregarding this uncertainty means too narrow a decision support and therefore a higher risk. With Big Loop the operators have a system for realistic uncertainty estimates.”

New workflow

According to company literature, Big Loop “tightly integrates static and dynamic domains, ensuring that all reservoir uncertainties are captured and used as input parameters to the reservoir simulator. This leads to a better understanding of the reservoir model, more reliable estimations of reserves [and] better informed decisions for future development scenarios.”

It works by supporting fully repeatable workflows, which allow easy updates when new data are acquired. This overcomes the restriction of having the seismic interpretation and depth conversion locked in before updates can be added. This way structural and velocity models can be updated.

In addition to being easy to update, Big Loop offers collaborative benefits. In an article for First Break, Skorstad and fellow authors Ingrid Aarnes and Knut Midveit described the tendency within companies to allow domain-specific goals to compete with the goals of the modeling project. “Moreover, the uncertainties tend to be sustained within each of the domains instead of aiming for a collective understanding of which parameters and inputs matter for achieving the end goal of the project,” they wrote.

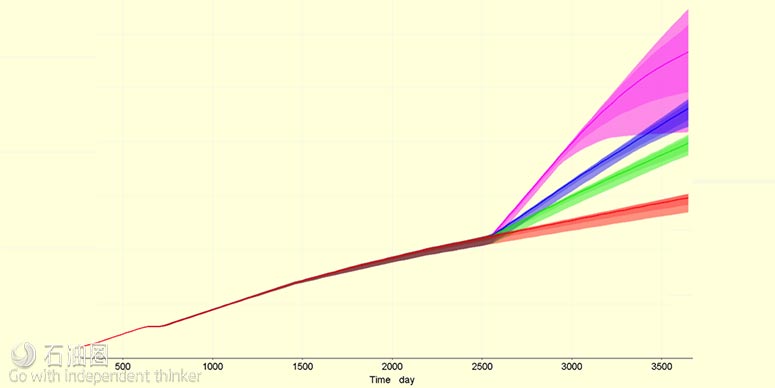

The solution is to support workflows throughout the entire process, from seismic interpretation to production forecasts. “The workflows can be automated and hence enable the fast generation of an ensemble of models,” they wrote. “Each model represents a probability configuration of the reservoir based on the specified uncertainties. The link between the geomodeling workflow and the reservoir simulation can be controlled via … Tempest ENABLE so that all asset members can contribute in the same time frame and as part of the same workflow.”

Working with the industry

Emerson recently published a case study with Petoro outlining the benefits of the new Roxar software. “The project for one field was completed in only three months, in due time to support decision-making,” Skorstad said. “Well placement optimization could be performed against multiple history-matched models rather than a single history- matched model, allowing a better founded risk assessment. Acceptable history matches were achieved without local modifications of the underlying geological model.”

The partnership with Statoil also has proven effective, enabling Emerson to further improve its “proxy” style of history matching based on research and field trials by Statoil. Statoil also contributed some of its proprietary algorithms to the Ensemble Smoother history matcher. Together the companies are examining the use of cluster and cloud computing within history matching and uncertainty management, which is essential for high-volume and integrated workflows.

Overall, Big Loop is intended to generate future production estimates, quantify uncertainty and minimize financial risk. “When the same data are used in different parts of the modeling chain, these should be used and understood in a consistent way, which the automated system supports,” Skorstad said.

石油圈

石油圈