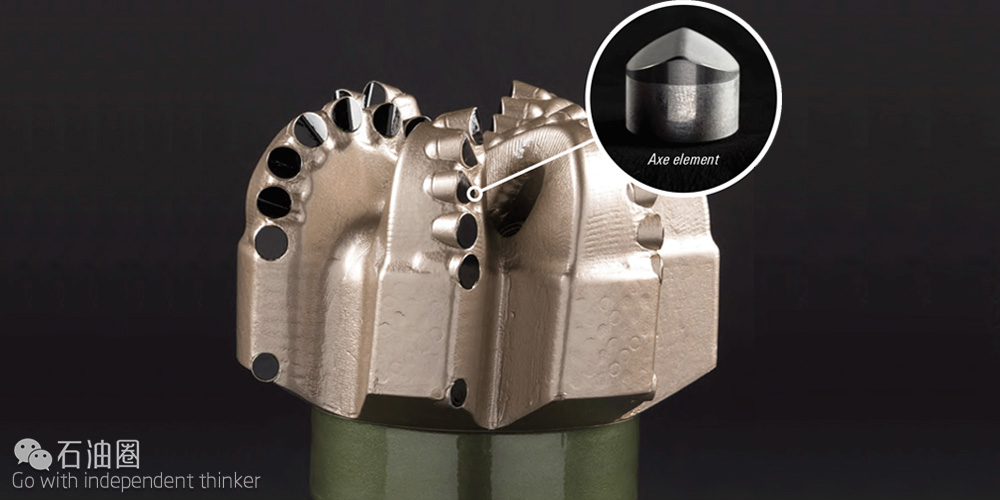

The latest cutter innovation from Smith Bits, a Schlumberger company, the Axe element features a unique ridge-shaped geometry that combines the shearing action of a conventional PDC cutter with the crushing action of a tungsten carbide insert (TCI). Placing these elements across the bit blade results in the AxeBlade* ridged diamond element bit, which enables significant improvement in ROP in a wide range of applications and improves steerability in directional wells. Field tests have demonstrated up to 29% improvement in ROP compared with premium PDC cutters using the same bit design.

Increased cutting efficiency for instant ROP improvement

Axe cutters employ a unique ridge-shaped geometry that fails rock in a new way—a combination of shearing and crushing. This cutting method achieves at least 22% deeper penetration to provide higher instantaneous ROP using the same weight on bit and rpm applied to conventional PDC cutters.

The ridge-shaped geometry yields a diamond table that is 70% thicker than a conventional cutter and provides higher frontal impact resistance compared with conventional cutters. This feature translates into improved durability and dull conditions for maintained maximum ROP throughout the run.

Enhanced control in directional applications

The reduced cutting force required by Axe elements translates to less overall torque, reduced reactive torque fluctuation, and better toolface control in curve applications. This advantage allows better build rates and higher overall ROPs, helping maximize production zone exposure and minimize drilling time.

APPLICATIONS

1.Vertical, curve, and lateral sections;

2.Any BHA configuration;

3.Medium to hard formations with unconfined compressive strengths (UCS) greater than 5,000 psi [35 mPa].

BENEFITS

1.Saves rig time and costs by delivering faster instantaneous ROP;

2.Achieves directional objectives in less time and maximizes production zone exposure.

FEATURES

1.Axe* ridged diamond element combines shearing and crushing actions to cut rock more effectively;

2.Thicker diamond table on cutter ridge increases cutter durability and maintains desired ROP throughout the run;

3.Ridge-shaped cutter geometry reduces cutting force requirement for less overall torque, less reactive torque fluctuation, and better toolface control.

Fitted with ridged diamond elements, the AxeBlade bit increases ROP and improves steerability through increased cutting efficiency and less torque fluctuation.

Unit Petroleum Company Boosts ROP 27% in Intermediate Section Targeting the Granite Wash

AxeBlade ridged diamond element bit enabled drilling with 20% less torque through interbedded shale, sand, and limestone formation onshore Texas

CHALLENGE: Improve ROP and reduce torque while drilling through interbedded formations of shale, sand, and limestone above the Granite Wash in the Anadarko basin.

SOLUTION: Deploy AxeBlade* ridged diamond element bit to drill the intermediate section.

RESULTS: Drilled the entire interval at 27% higher ROP and generated 20% less torque.

Improve drilling speed in intermediate section

While pad drilling in the Texas portion of the Anadarko basin, Unit Petroleum Company sought to improve single-run ROP in the 8¾-in intermediate section for future offset wells in the area. The interval to be drilled is primarily shale with harder interbedded layers of sandstone and limestone, with unconfined compressive strength (UCS) range of 3,000 to 15,000 psi.

Using a directional motor, the operator wanted to drill the intermediate section to the kickoff point at the top of the targeted Granite Wash formation. Because of nearby wells on the pad, the interval to be drilled typically included a slight nudge.

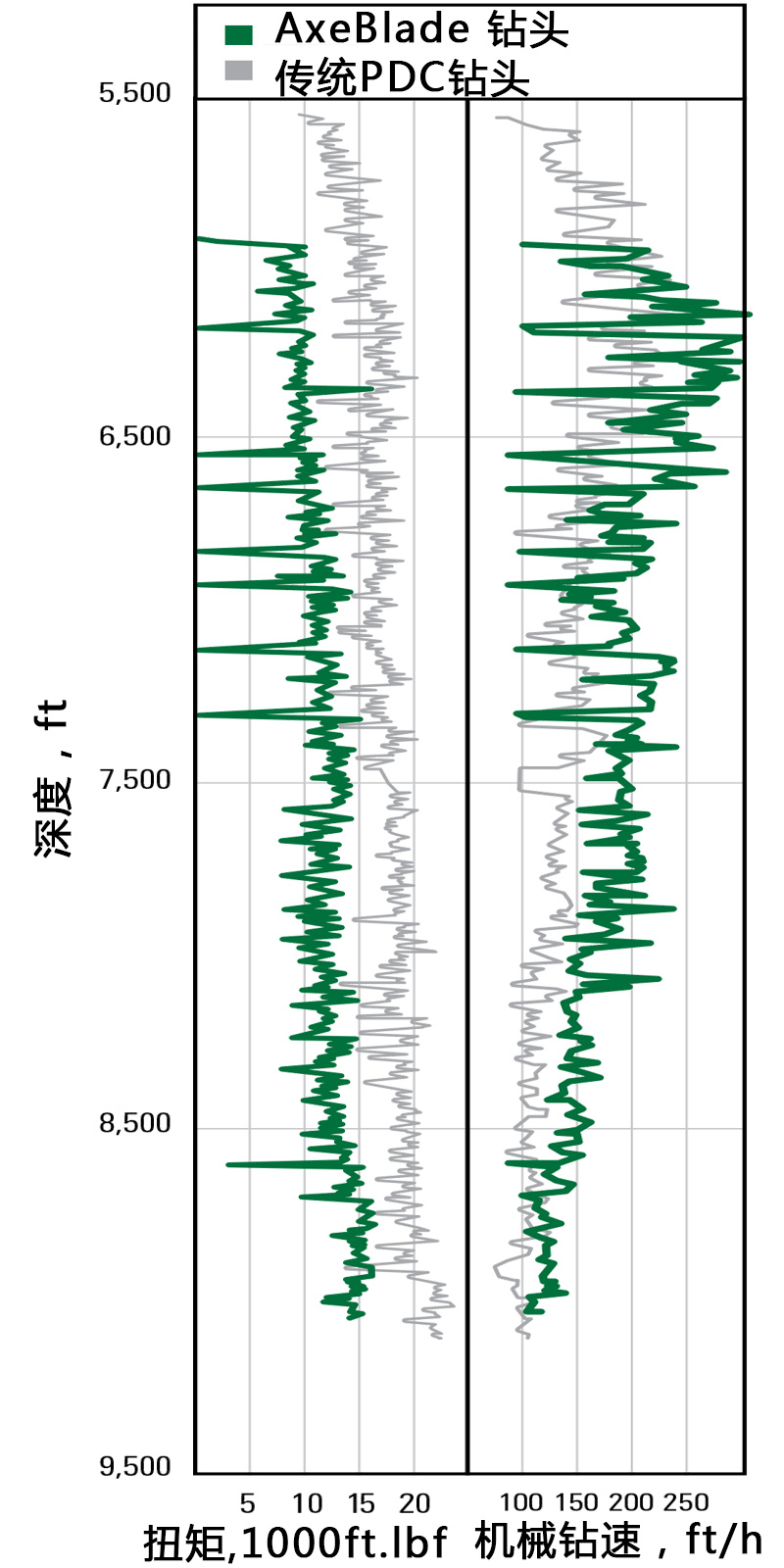

On an offset well approximately 5 miles from the planned Mahler 108-1H well, Unit Petroleum drilled the 8¾-in intermediate section using an 8¾-in MSi616PX premium PDC bit from Smith Bits, a Schlumberger company. From 5,545 to 9,115 ft, the operator achieved an ROP of 75.16 ft/h, and the bit exhibited relatively minimal cutter wear.

Deploy AxeBlade ridged diamond element bit for improved cutting efficiency

To increase ROP over the offset well when drilling Mahler 108-1H, Schlumberger suggested that Unit Petroleum deploy an AxeBlade bit for instantaneous ROP improvement. An 8¾-in bit with ridged diamond elements was selected to enable faster speeds and improve directional control through higher frontal impact resistance and increased cutting efficiency.

The aggressive geometry of the unique ridge shaped element achieves at least 22% deeper penetration than conventional PDC cutters at the same drilling parameters. Additionally, the ridged diamond elements enable less overall torque and fewer torque fluctuations for smoother drilling operations. With better toolface control, the AxeBlade ridged diamond element bit achieves better ROP, especially in directional drilling operations.

Increase ROP 27% and generate 20% less surface torque

Prior to drilling, an analysis using the IDEAS* integrated drillbit design platform determined that the AxeBlade bit would provide enhanced cutting efficiency through instantaneously increased ROP and lower drilling torque compared with the premium PDC bit used on the previous well.

Unit Petroleum drilled the Mahler 108-1H well’s intermediate interval from 5,918 to 9,047 ft in a single run at an ROP of 95.54 ft/h, a 27% increase over the offset well. Under similar drilling parameters and using the same cutting structure layout, the AxeBlade bit not only increased ROP but generated 20% less surface torque and impressive dull condition. This improved drilling performance saved the operator 14.75 hours of rig time. The higher ROP enabled by the bit means that the operator can finish the well sooner and reduce the cost of operations.

ROP rose 27% and surface torque fell 20% in the Mahler 108-1H well

The dull condition of the AxeBlade bit after drilling the Mahler 108-1H well demonstrates that it can be run in a similar application in future wells with the potential to increase WOB to yield even greater ROP gains.

石油圈

石油圈