RAPTOR™ 2.0 CASED-HOLE EVALUATION SYSTEM,Revealing bypassed reserves with accurate through-casing reservoir characterization

With 250% more sensitivity than standard two-detector pulsed-neutron tools, the Raptor™ 2.0 system delivers definitive oil and gas saturation data.There’s more out there. The only questions are where and how much. Our Raptor 2.0 cased-hole reservoir evaluation system reveals and quantifies what lies behind your casing.

The five-detector Raptor 2.0 tool is an exponential leap forward in pulsed-neutron technology, reliability, and service excellence. The result of decades of global experience and expertise, our system finds and defines oil and gas volumes to within a few saturation units.

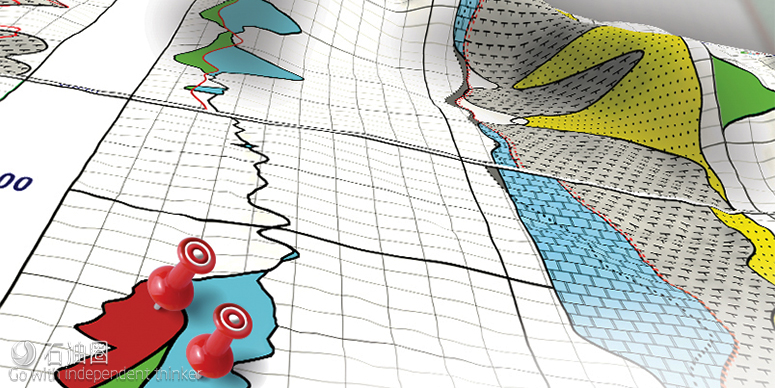

The Raptor 2.0 system provides clear and accurate reservoir data through first-of-its-kind hardware, high-fidelity response characterization, advanced petrophysical workflows, and a wide range of answer products. Analyzed by our expert petrophysicists, Raptor 2.0 logs capitalize on industry-leading tool sensitivity and resolution to give you a definitive roadmap to efficiently booking more reserves and increasing production.

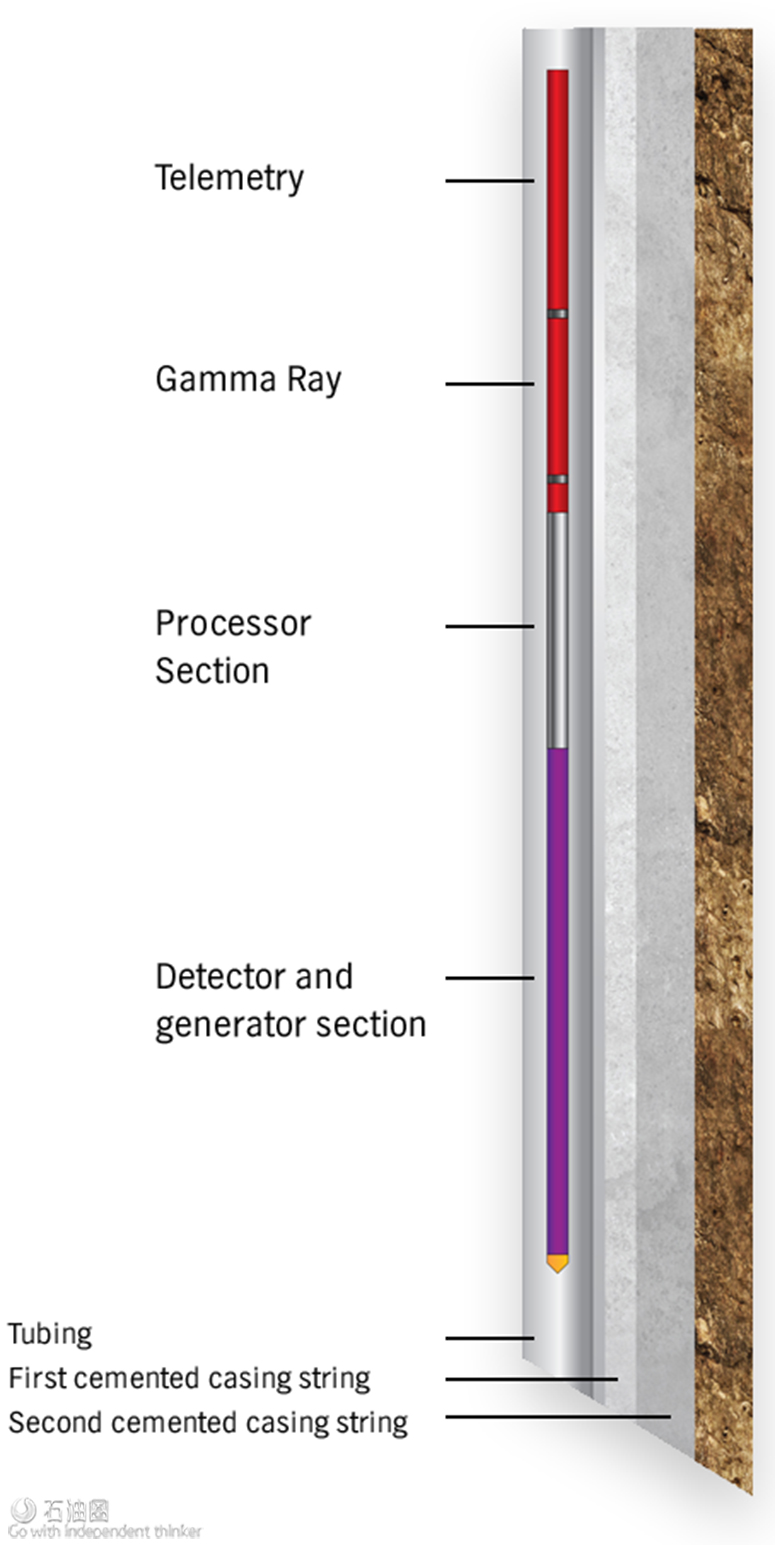

HARDWARE

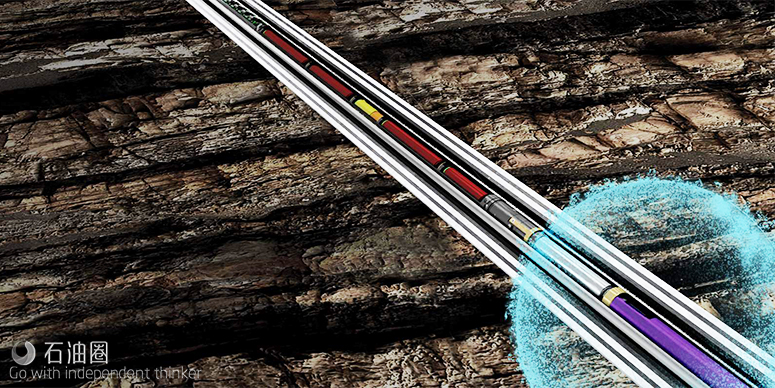

The Raptor 2.0 tool comprises cutting-edge technology to deliver accurate reservoir measurements in a wide range of well configurations. The tool combines a high-output pulsed-neutron generator, four spectroscopy sensors—each containing a lanthanum-bromide (LaBr3) scintillation detector—and a fast-neutron counter.

SPECTROSCOPY SENSORS—The Raptor 2.0 tool uses four sensors rather than two to increase the gas-saturation measurement sensitivity by 250% and investigate a larger volume of the reservoir.

LaBr3 SCINTILLATION DETECTORS—The Raptor 2.0 tool incorporates advanced scintillation detectors, which provide 3 times greater peak resolution for spectral analysis compared to bismuth-germanate (BGO) scintillators; 10 times brighter light output for improved signal-to-noise ratio compared to gadolinium-orthosilicate (GSO) scintillators; and 30 times better temperature stability compared to BGO scintillation detectors.

FAST-NEUTRON COUNTER—This device measures the precise neutron-emission rate from the pulsed-neutron generator, which provides superior log quality control, data timing accuracy, and response characterization.

T-100 CALIBRATOR—The Raptor 2.0 is the only pulsed neutron tool in the industry that offers a multipoint oil and gas sensitivity calibration. This feature delivers calibrated, factory-spec logging performance and measurement consistency between tools regardless of tool age or the well environment.

HIGH-SPEED TELEMETRY—The upgraded telemetry cartridge—which includes auxiliary measurement devices, casing collar locator, and accelerometer—enables compatibility with other Weatherford production-logging and cement-evaluation tools.

Raptor 2.0 cased-hole evaluation system applications

(1)Quantifying formation oil, gas, and water saturations

(2)Pinpointing fluid contacts

(3)Classifying hydrocarbon types

(4)Monitoring changes in the reservoir during production

(5)Locating bypassed reserves in mature wells

(6)Characterizing pressure-depleted zones

(7)Distinguishing between gas and tight zones

(8)Assessing enhanced-oil-recovery (EOR) performance

(9)Identifying producible gas in thin beds

FUNCTION

The Raptor 2.0™ tool uses a pulsed-neutron generator to emit high-energy neutrons into the formation. The neutrons interact with formation elements and release gamma radiation, which is sensed by the four LaBr3 detectors in the tool. The amount and quality of the sensed radiation is used to derive saturation.

The tool captures saturation data in enhanced sigma, enhanced carbon-oxygen (C/O), and our proprietary N-Vision acquisition modes. These techniques accurately quantify oil-water and gas-liquid saturations in any type of reservoir, including low-porosity environments.

PLAN—We develop a customized response characterization and logging program for each well based on completion details, reservoir data, and customer objectives. The Raptor 2.0 system can run simultaneously with additional tools and sensors to increase operational efficiency.

CALIBRATE—The unique T-100 calibrator confirms that, for every job, the Raptor 2.0 tool will not only provide the same fluid sensitivity and responsiveness as it did when new, but that it will also deliver a response consistent with all Raptor 2.0 tools around the world.

RUN—With an outside diameter of only 1.69 in. (42.9 mm), the Raptor 2.0 tool can be deployed through tubing in almost any cased-hole well environment.

LOG FOR OIL AND WATER SATURATION—Logging in sigma or C/O mode, the Raptor 2.0 detector array records formation gamma ray counts that originate from neutron-capture or inelastic reactions. Combined with the high-fidelity, response-characterization modeling, our petrophysicists can determine oil, water, and gas saturations.

LOG FOR GAS SATURATION—Logging in N-Vision mode, the large detector array senses the gamma interactions in gas-bearing formations, which are used to calculate pore-fluid density and gas saturation. Effective regardless of water salinity or oil-water saturation, the N-Vision technique provides precise gas-liquid saturation data in porosity ranges as low as 5%.

LOG FOR PRODUCTION DIAGNOSTICS AND WELL INTEGRITY—The Raptor 2.0 neutron generator causes momentary radioactivity in the oxygen contained in nearby water molecules. This activation response is used to determine the velocity and direction of water flow inside and outside of the casing.

WORKFLOWS

The Raptor 2.0 cased-hole reservoir evaluation system is more than just hardware. We created a comprehensive petrophysical system to capitalize on the most sensitive pulsed-neutron tool ever built. Once the raw, real-time data reaches the surface, we begin the petrophysical workflows that ultimately provide precise and revealing answer products.

The data from each job is analyzed by our dedicated production petrophysicists. Each member of this team has completed an extensive course on Raptor 2.0 system petrophysics and related cased-hole production petrophysics disciplines.

SINGLE-WELL RESPONSE CHARACTERIZATION—Every well logged by the Raptor 2.0 system is characterized individually using Monte Carlo modeling. This feature predicts the curve response based on hole size; casing size and weight; formation lithology; borehole and formation fluid density, salinity, and composition; and production tubing strings and their content. This enables characterization of a wide range of completion and reservoir conditions, including multiple casing and tubing strings, wellbore and annular fluids, foam cement, condensate, screens, and EOR processes.

FORMATION-VIEW FUNCTION—This analysis provides evidence that the tool is acquiring data from the formation, which is especially important in complex wells, including those with multiple casing or production-tubing strings inside large casing.

SHALE HANDLING AND MINERALOGY PETROPHYSICS—The Raptor 2.0 system uses mathematical, petrophysical processes for shale handling and lithology normalization. This advancement replaces an analyst’s opinion with an auditable petrophysical workflow.

FOUR-DETECTOR MIXING—The four-detector array enhances spectroscopic C/O and sigma measurements and provides dimensional saturation measurements. This unique feature enables formation slicing, or saturation measurements at different depths of investigation that respond to different vertical resolutions.

PETROPHYSICAL SOFTWARE—The Raptor 2.0 system software is intuitive, easy to use, and transparent. At any step of the process, our software enables the end user to sit side-by-side with the production petrophysicist to see the analysis behind the answers.

ANSWER PRODUCTS

The versatile Raptor™ 2.0 reservoir saturation tool provides an open canvas for developing new formation-evaluation answer products, and our portfolio is ever-expanding. Some of the most applicable products are described below:

(1)FLUID SATURATION

Raptor C/O :Measuring inelastic carbon-oxygen and calcium-silicon ratios from the four detectors, the C/O model provides basic lithology and oil-water saturation. Interpretation uses high-fidelity Raptor 2.0 well characterization combined with customer-provided porosity and shale volume. The calibrated field model allows for interpretations in wells lacking openhole logs. The simultaneous solution for lithology and saturation enables identification of, and correction for, variations in carbonate cementation and calcite stringers that can artificially inflate oil saturation.

Raptor Sigma:Derived from a mixture of the sigma measurements from the four-detector array, the sigma model delivers the diffusion-corrected formation sigma. This enables a variety of views at different formation depths. Sigma measurements are then used to calculate water saturation in high-salinity environments using a volumetric property-summation technique.

Raptor Gas:By calculating the pore-fluid density, the gas answer product determines gas-liquid saturation. The proprietary N-Vision technique is independent of formation water salinity and oil-water saturation and is 100 times less sensitive to mineralogy and shale than a standard sigma measurement.

Raptor 3-Phase:For reservoirs that contain all three fluid types, the 3-Phase model combines Raptor Gas with either Raptor C/O or Raptor Sigma to calculate water-oil-gas saturations.

The Raptor 2.0 system includes many innovations—including tool calibration, mineralogy algorithms, characterization, detector mixing, and petrophysical workflows—that produce accurate saturation data in challenging environments.

(2)NEW WELL EVALUATION

In wells where openhole logs are not planned or available, these answer products can supplement or replace some aspects of missing openhole data sets by providing porosity, V-shale, and basic mineralogy.

Raptor CFM:The calibrated field model (CFM) calibrates the Raptor 2.0 curves to core or openhole log data in the same well. Once complete, the Raptor 2.0 system can reproduce the openhole curve data in subsequent wells within that field and reservoir stratigraphy with no modification or histogram normalizations required. This preserves the geostatistical significance of the data. The resulting porosity and shale volume can then be used as input to any of the Raptor 2.0 fluid saturation products.

Raptor OWM:Similar to the CFM, the offset well model (OWM) calibrates Raptor 2.0 data to core or openhole log data from an offset well. Working in subsequent wells within that field and reservoir stratigraphy, the Raptor 2.0 system can then reproduce the openhole curve data with no modification or histogram normalizations required. The data, including porosity and shale volume, can then be used as input to any of the Raptor 2.0 fluid saturation products.

Raptor CCN:The calibrated, characterized, and normalized (CCN) model determines porosity and shale volume by using the standalone calibrated and characterized Raptor 2.0 curves with no linking or calibration of the curves to openhole well data. The resulting porosity curve is normalized to a known porosity to properly scale the porosity output. The derived porosity and shale volume can then be used as inputs to any of the Raptor 2.0 fluid saturation products.

Raptor Openhole Emulation Curve Package:This data package is designed for customers who use pulsed-neutron data to emulate openhole density, neutron, and Rt curves. This data set delivers calibrated pulsed neutron curves that have a standard value and sensitivity and do not need to be transformed with a histogram.

(3)SPECIALTY DIAGNOSTIC APPLICATIONS

Gravel Pack Evaluation:Using a combination of silicon activation and spectroscopic analysis techniques, Raptor 2.0 system measurements can determine the proppant distribution and annular pack percentage for openhole and cased-hole gravel pack completions.

Oxygen Activation:Configured with one or more gamma ray tools above, below, or above and below the neutron generator, the Raptor 2.0 system can detect water flow within or behind the casing. The large detector array enables water velocity calculations to be made across a wide range of flow rates.

石油圈

石油圈