Cascade3 significantly improves long-term performance of water injection wells, extending well life and increasing overall field production.

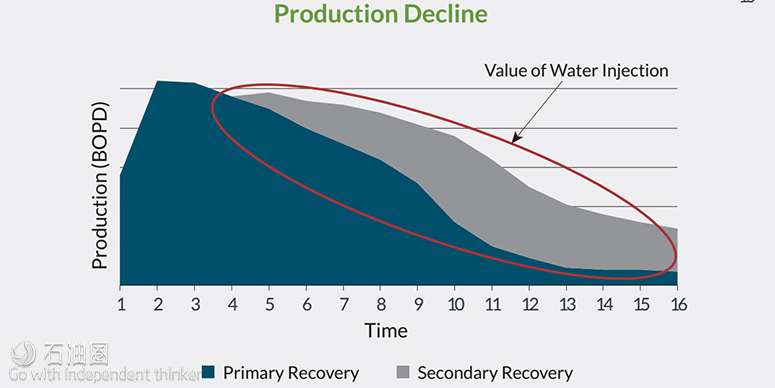

In conventional reservoirs, a significant portion of oil production is driven by water injection into sand prone reservoirs. Waterflooding, whether applied at field start-up or as a secondary recovery technique, can increase production rates and boost oil recovery by

maintaining pressure and ensuring a more effective sweep of the reservoir.

In heterogeneous reservoirs and unconsolidated formations with fine or poorly sorted sands, loss of injectivity is commonly associated with sand fill in the wellbore. These premature failures of water injection wells result in lower reservoir pressure, higher gas/oil ratio

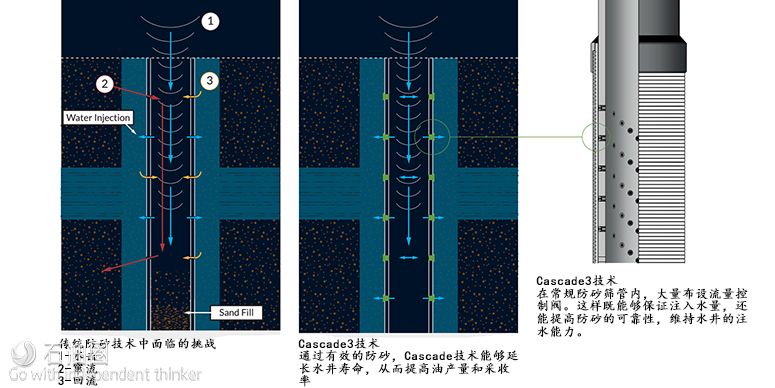

In water injection wells, sand production occurs in the periods immediately following injection shut-down because of backflow, crossflow between zones or wells, and water hammer effects. Conventional sand control techniques which perform well in steady state production are not designed to control transient sand production and cannot always be effective in water injection applications.

Cascade3 technology provides a unique solution to these problems by isolating fluid in the completion annulus and locking injection water into the formation to eliminate the transport mechanism for sand production entirely. The result is increased injection reliability providing ongoing waterflooding without costly re-drills or frequent well clean-outs.

Features

-Simple design and installation

-Radially mounted in screen base pipe with no effect on OD / ID

-10,000BWPD injection per joint

-Compatible with gravel pack and standalone screen completions

Benefits

-Eliminates crossflow reducing screen erosion

-Eliminates backflow and fines movement into the wellbore

-Prevents water hammer effects

-Improves injectivity and reservoir sweep

-Extends water injector life

Failure mechanisms can result in a number of negative outcomes, limiting production, and ultimately reducing well life. Cascade3 eliminates these failure mechanisms.

Conventional Sand Control Challenges

1 – Water Hammer

2 – Crossflow

3 – Backflow

Cascade3 Solution

By preventing sand production, Cascade3 extends injection well life resulting in more oil production and greater recovery

Cascade3 Technology

High density of flow control valves mounted within conventional sand screens allows high water injection rates while increasing sand control reliability and maintaining injectivity over time.

石油圈

石油圈