The Parque das Conchas (BC-10) fields lie in water depths ranging from about 5,000 ft to 6,500 ft in the Campos basin offshore Brazil. The subsea fields are tied back to a floating production, storage, and offloading (FPSO) vessel, which has a processing capacity of 100,000 bbl of oil equivalent per day. Constant swells and hostile conditions at the seabed create significant technical challenges for operations.

Brazilian regulatory requirements mandate periodic well tests during production. Traditionally, deepwater well testing requires complicated infrastructure both subsea and topside, which not only makes the field development more complicated but also increases project installation time, risk, and cost. The operator required a reliable, cost-effective solution that would enable real-time well monitoring while satisfying the stringent regulations.

CHALLENGE

Improve production well testing economics while meeting stringent regulatory requirements in the deepwater Campos basin offshore Brazil.

SOLUTION

Deploy PhaseWatcher subsea multiphase flowmeters with Vx technology instead of conventional well test equipment.

RESULTS

(1)Saved operator USD 12 million in equipment costs.

(2)Increased production by 1,000 bbl/d.

(3)Improved data quality by replacing periodic well tests with continuous monitoring.

(4)Satisfied all regulatory requirements.

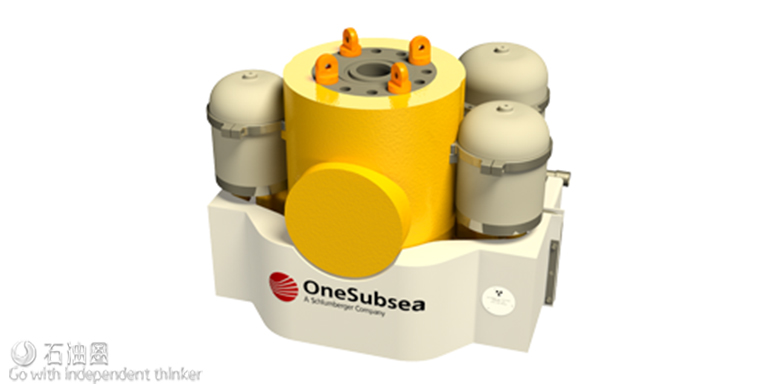

PhaseWatcher Subsea Multiphase Flow Meter

The OneSubsea PhaseWatcher fixed multiphase well production monitoring equipment uses the same Vx technology as the topside version. Several different compact configurations of this subsea equipment are available, offering a solution for any subsea infrastructure.

The PhaseWatcher subsea multiphase flowmeter with Vx technology is specifically designed to provide critical well diagnostic information without the complexity of conventional testing operations. The compact device can measure individual fluid phases in real time without separation and provide flow rate measurements throughout the life of the field.

Before using the technology, it was necessary to obtain authorization from the regulator, Agência Nacional do Petróleo (ANP). The approval process—the first of its kind in Brazil—involved two stages:

(1)Obtain authorization to commercialize the multiphase flowmeter in the Brazilian market.

(2)Obtain authorization to use the multiphase flowmeter in lieu of conventional periodic well testing for production allocation.

The operator and OneSubsea worked in close cooperation to present the case to ANP and succeeded in obtaining authorization. In the first phase of the project, eight PhaseWatcher flowmeters were configured and successfully installed, one per well, in retrievable arrangements on the subsea Christmas trees.

Less topside equipment led to a reduction in the number of risers, saving the operator USD 10 million. Eliminating the need for a test separator saved an additional USD 2 million; it also reduced the deck space required.

The continuous, high-resolution well flow measurements provided by the subsea flowmeters in real time were far superior to the data from conventional well test equipment (test lines, manifolds, separators). The improved monitoring helped increase production by 1,000 bbl/d and enhanced overall recovery. Pleased with the results, the operator decided to use the flowmeters in subsequent stages of the project as well. A total of 21 PhaseWatcher flowmeters were installed, resulting in further savings and production gain for the operator.

Specifications

It can be mounted for continuous monitoring of each individual well or in a test header for alternate well testing. Regardless of whether the flowmeter is retrievable or nonretrievable, single-hub, dual-hub, or inline, it offers all the benefits of Vx technology.

Inline 10K

This is the base configuration of the PhaseWatcher equipment; only the metering section is integrated into the infrastructure using standard interface flanges. This configuration is normally installed on a production tree as part of a retrievable choke bridge or flow control module and is not independently retrievable.

Sizes: 29, 52, 65, and 88 mm (equivalent piping interface of 3, 5, 6, and 8 in)

Pressure rating: Up to 10,000 psi

Weight: Up to 1,950 kg (submerged)

Dual Hub 10K

The dual-hub configuration is a fully retrievable version of the PhaseWatcher equipment. Compared with the inline design, this configuration has integrated piping upstream of the venturi section, making it possible to fully retrieve the unit from the subsea infrastructure. The dual hub can be configured with a clamp set for ROV operation during installation or removal in deeper waters, or it can be configured with a removable clamp set for diver installation in shallow water.

Sizes: 29, 52, 65, and 88 mm (equivalent piping interface of 3, 5, 6, and 8 in)

Pressure rating: Up to 10,000 psi

Weight: Up to 3,500 kg (submerged)

Inline 15K

In 2009, we further developed the 10,000-psi design for 15,000-psi applications. It has three separate electronics pods that protect the electronics from the environment—two transmitter pods and one power and communications (PCom) pod.

Sizes: 29, 52, and 88 mm (equivalent piping interface of 3, 5, and 8 in)

Pressure rating: 10,000–15,000 psi

Weight: Estimated 1,300 kg (submerged)

Dual Hub 15K

The dual-hub 15,000-psi PhaseWatcher equipment configuration is also fully retrievable as part of a retrievable choke bridge or flow control module. Just as with the retrievable 10,000-psi design, this configuration also offers flexibility for installation and retrievability. This is a key consideration not only during the project execution phase but also in case of any unforeseen subsea challenges.

Sizes: 29, 52, and 88 mm (equivalent piping interface of 3, 5, and 8 in)

Pressure rating: 10,000–15,000 psi

Weight: Estimated 3,000 kg (submerged)

石油圈

石油圈