是什么让企业在动荡时代站稳脚跟?墨守成规总归不是妙计。

来自 | E&P

编译 | 二丫 影子

一个行业的发展离不开方法的改进和效率的提高。而近些年来,石油行业的繁荣主要得益于先进技术和先进工具的大量应用,从而造就了运营效率的指数式增长。

页岩气领域近几年的技术进步以及效率的提高让人印象深刻,而这种技术革新还会继续下去。对于运营商来说,这些新技术的应用与否很可能决定其成败。美国页岩气之父George Mitchell带头推动了水力压裂法的使用,这项突破性技术带来了美国2010年以来的页岩气繁荣。页岩气开采被认为是本世纪迄今为止最为伟大的创新,但事实上这并不是一项新技术,而是由上世纪90年代末的技术发展而来。这种技术发展开创了一个崭新的页岩时代,同时也推动了美国油气行业的革命。

新涂层应用强化二氧化硅粉尘控制

未经处理的压裂砂(左)与用A处理过的压裂砂(右)相比,显示出更佳的粉尘控制

业内仍然在持续关注水力压裂中的二氧化硅粉尘排放问题。佛罗里达的一家公司与业内专家合作,运用50多年的涂料专业只是,采用涂料应用系统,研发出一种高效的硅粉控制技术。

作为该公司的新一代专利型硅粉控制支撑剂涂层技术,A能够将二氧化硅粉尘量减少99%,符合职业安全和卫生管理局新规定的限值和标准。当应用于压裂砂时,A可通过水力压裂供应链,提供连续的二氧化硅防尘保护。该技术可实现从砂厂到井口的持续保护,简化压裂砂的物流运输,并实现快速跟踪。

A易于应用,无需干燥或固化,可以各种压裂流体兼容,同时也不会对油井性能产生不利影响。使用SandTec涂层技术,作业人员再也无需设置、拆除或维护机械除尘控制系统。

新型水泥浆体系:强度更高,密度更低

N是一款低硅酸盐含量的水泥浆体系,相对于常规体系,N的密度更低,但抗压性能、弹性和抗剪切力都更强。N是D公司的最新产品之一,合理结合了硅酸盐水泥与特殊材料的物化性质。N是第一款可同时提高环空液压密封性能和弹性的低硅酸盐含量水泥浆体系。

通常,固井水泥浆的密度越大,抗压性能越强,水泥密度降低,相关性能也会随之降低。然而,从1.2lb/gal以上(含1.2lb/gal)水泥浆体系对比中可以看出,N体系的性能更加优良,可将抗剪切强度提高79%,抗压强度提高11%,弹性提高15%,抗压强度与杨氏模量比值提高30%。该体系与2016年初开始商业推广,截至到目前,已应用了超过一百万桶泥浆,为90多家用户提供了优质服务。

新型生物可降解压裂球,桥塞溶解更快

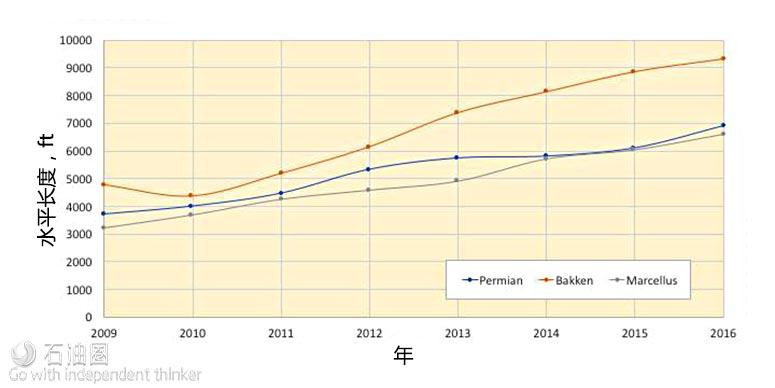

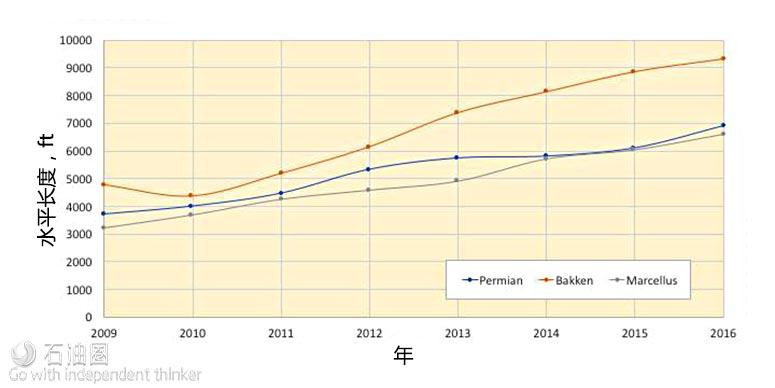

L公司的水力压裂/完井解决方案可得到更长的水平长度

生物可降解压裂球和桥塞能够在几天或几周之内即可降解,油气行业一直在努力寻找这类技术。L公司研发出了一种微生物溶液,可在一个很大的温度范围内,以更快的速度溶解聚乳酸聚合物和可分解封隔器,从而更快地实现产量上升和创收。

另外,L还在开展有关水力压裂和完井的解决方案,如原微生物表活剂生产、压裂损伤修复以及用作携砂液的聚合物,这些解决方案都可以有效增大油井的水平长度。

可溶解合金提高滑套和PNP作业灵活性

M公司推出了S可溶镁合金,具有高强度、高延展性等性能,在盐溶液或淡水中具有可控的溶解表现。S合金可用于制作滑套,以及PNP作业中的压裂球。S合金广泛的应用范围,使设计师、油服公司和作业人员都能够确信,这一材料在井下可以进行可预测的可靠工作。使用S合金,可降低未被腐蚀的镁上返到地面的风险。

新型树脂材料可承受20,000psi高压

T公司是一家高性能聚合物生产商,可为内管注水泥设备提供一种新型的非金属复合材料。P是一种新型高强度热固性树脂,可在桥塞、阀门和给装外罩中的铝。该产品可承受超过20,000psi的强度,并具有204℃(400℉)的额定温度。这种材料易于加工和钻碎,速度比铝快20倍,可节省出数小时的钻机时间成本。

与系列中的其他产品一样,P可以在高输送量的条件下,使用低成本设备实现模制。新型高强度热固性树脂进一步丰富了T公司的低阻力和耐磨聚合物产品系列。

固体油溶性示踪剂优化生产分析

在原油开采中,油溶性示踪剂(OST)多用于生产分析,其分析原理主要来源于,在采出液中分离得到的化学示踪剂能够精确反应井下开采状况。一般认为,OST回收率与实际生产状况的比例关系是化学示踪剂准确性的关键。众所周知,任何泵入油藏的液体都会对油藏压力产生影响,进而会造成油藏生产数据的波动。而从实际生产状况来看,由于注入OST与压裂液的量相比非常少,并且会迅速排出井筒,所以通过OST获得的油藏历史数据并不能长期适用。虽然OST的这一缺点已存在多年,但并没有出现新的技术来改善这一问题,油气行业无奈选择了忍受。

为了解决这一问题,目前已有34种OST产品投入了完井和重复压裂市场,在压裂作业中,这些固体微粒OST在混合桶内与支撑剂混合后,一并被注入油藏。在到达指定位置后,OST会在压裂裂缝内固定,避免了压裂作业中由于压力波动造成OST反排出油藏的问题。在压裂作业完成后,只有当含有OST的固体颗粒与油接触后才会释放化学示踪剂。通过示踪剂的缓释,可显著延长OST的使用时间。

下期关键词:压裂工具

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

二丫:131-3255-0596;zhanglingyu@fonchan.com

For English, Please click here (展开/收缩)

NEW COATING APPLICATION ENHANCES SILICA DUST CONTROL

Silica dust emissions from hydraulic fracturing remain an ongoing concern for the industry. A collaborated with industry experts, applied 50-plus years of coating expertise and adapted a coating application system to develop an effective technology for silica dust control. SandTec, A patented next-generation silica dust control proppant coating technology, reduces respirable silica dust by up to 99% to within the Occupational Safety and Health Administration’s new permissible exposure limit and action level. When applied to fracture sand, SandTec provides continuous silica dust protection across the hydraulic fracturing supply chain. The technology provides continuous protection from sand plant to wellhead, and it simplifies and fast-tracks fracture sand logistics. SandTec also offers ease of application without drying or curing and compatibility with a variety of fracture fluids while not adversely affecting well performance or occupying valuable fracture site real estate. With this technology there is no need for setup, tear-down or maintenance of mechanical dust control systems. SandTec offers reduction of site dust that can adversely affect equipment, and it is an environmentally friendly U.S. Department of Agriculture-certified 100% biobased product under the BioPreferred program.

NEW CEMENT SYSTEM OFFERS ENHANCED MECHANICAL PROPERTIES, LOWER DENSITY

N cement is a low-Portland cement system designed to deliver better mechanical properties at a lower density than conventional cement systems. This technology is the result of D’s R&D team discovering physicochemical synergies between specialized materials and Portland cement. The improved mechanical properties can include increased ductility for better resistance to cyclical stress loading during fracturing stages; increased “strain to failure,” improving robustness for the life of the well; and improved compressive and tensile strengths at given density. N cement has demonstrated more than 10% improvement in compressive strength and up to a 15% improvement in elasticity compared to a conventional cement system with greater than a 1-parts-per-gallon higher density. This combination of enhancements results in a compressive strength to Young’s modulus ratio that can be 30% higher than the higher density conventional cement systems. N cement enables lighter weight cement systems with easier and improved mechanical properties without increasing cost to the customer or requiring additional rigsite equipment. This new product was commercially introduced in early 2016, and to date more than 1 MMbbl have been pumped for more than 90 customers.

NEW BIODEGRADABLE FRACTURING SLEEVE BALLS, PLUGS DISSOLVE FASTER

Operators have struggled with biodegradable frack sleeve balls and plugs as they can take several days or weeks to dissolve. L Solutions LLC has developed a microbial solution that dissolves polyactic acid polymer and dissolvable packers much more quickly—in hours rather than days—at a wide range of temperatures. This allows much quicker production ramps and revenue generation. L also is working on hydraulic fracturing/ completion solutions such as in situ biosurfactant production, fracture damage repair and biopolymer utilization for carrier fluids. These solutions support the trend toward increasing lateral lengths that are otherwise constrained by coiled tubing limitations (see figure). For example, L’ biodegradable biosurfactant flowback solution can efficiently decrease water surface tension to the desired 28 to 30 dynes/ cm range.

DISSOLVABLE ALLOYS OFFER FLEXIBILITY IN SLIDING SLEEVE, PNP OPERATIONS

M offers S dissolving magnesium alloys, which encompass a wide range of material properties for highstrength or high-ductility applications as well as controlled dissolution performance in salt solutions or freshwater. S alloys are being used in sliding sleeve and plug-and-perf (PNP) applications as fracturing balls and for dissolving fracturing plug components in North American oil and gas wells. The wide range of SoluMag dissolving magnesium alloys was developed to give the designer, service company or operator the confidence that the material will work in downhole conditions predictably and reliably. Using S lowers the risk of uncorroded magnesium returning to surface. Giving the user the data as to how this material performs in the wide range of operating conditions will allow the completion to go smoothly without intervention.

NEW RESIN OFFERS MORE THAN 20,000 PSI OF STRENGTH

M, a producer of high-performance polymers, offers a new nonmetallic composite material for inner-string cementing equipment. P is a new high-strength grade of thermosetting resin for replacing aluminum in plugs, valves, noses and housings. The product offers more than 20,000 psi of strength as well as temperature ratings that exceed 204 C (400 F). The material is easy to machine and drills out up to 20 times faster than aluminum, delivering several hours of rig time cost savings. Like the other products in M’s P product line, P is easy to mold using low-cost equipment in high throughput. The new high-strength grade of thermosetting resin complements M’s product line of low drag and wear-resistant polymers.

SOLID OST ENHANCES PRODUCTION ANALYSIS

The utility of oil-soluble tracers (OST) in production analysis is based on the assumption that chemical tracer recovery in produced oil accurately reflects downhole oil production. How closely this holds true is a function of how closely OST recovery is proportional to actual oil production. Any fluid pressure pumped into a formation can be squeezed back out of the formation by in situ pressure and can result in false-positive oil production readings. Historical data recovery from liquid OSTs has been relatively short-term. This is because injected OST liquid volumes are low relative to total injected fracture fluid volumes and consequently quickly play out. This has been a well-known and generally accepted industry norm for decades, with no known practical alternative. To address these limitations, 34 solid OST products are now available to the completion and refracturing market. These solid particulate OSTs are injected into the blender tub along with the proppant and carried out into the formation during hydraulic fracturing. These particulates then remain locked deeply in situ in the fracture pack, thereby eliminating the effect of formation pressure squeezing the OSTs back out of the formation as the fracture pressure wave subsides. The particulate OST only releases its chemical tracer signature when movable oil comes in contact with the embedded particulate. This results in longer term datasets, with some instances exceeding two years of tracer recovery.

未经允许,不得转载本站任何文章:

石油圈

石油圈