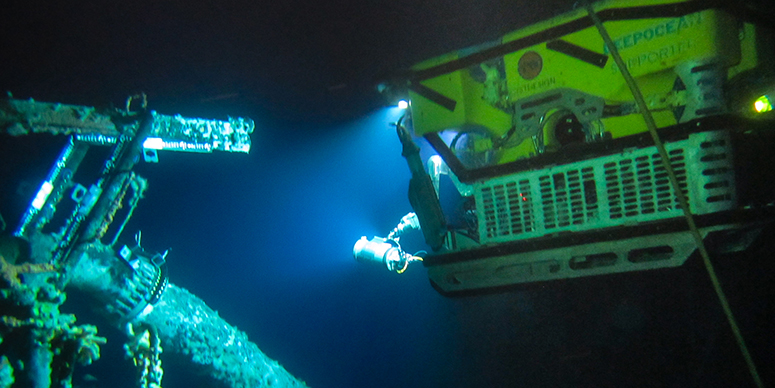

Ultra deepwater discoveries play a crucial role in replacing global reserves. The world’s operating companies are now confronted with new challenges to ensure that the reserves are discovered, appraised and developed safely and efficiently. Subsea safety systems are critical in delivering safe, compliant and efficient operations in all subsea applications.

Current subsea operations require superior functionality, performance and reliability because production is occurring in increasingly deeper water, higher pressures and higher temperatures. Certain subsea tools have been developed using an integrated design and qualification process, ensuring that equipment meets the highest performance criteria.

Performance Under Pressure

Where there are deepwater operations, there are challenges. Fifteen years ago, 5,000 feet of ocean depth was considered deepwater. However, with new technology, operators are successfully drilling at 6,000 feet to 10,000 feet and beyond, and more companies are exploring hydrocarbons at these increased depths.

The deeper the explorations, the more expensive the projects become. Therefore, large reservoirs with the biggest impact on global reserves should be targeted. If the volumes of hydrocarbons are significant enough, then it is worth the investment of exploring and drilling in deeper water. With the success of hydrocarbon finds in deep waters—such as the Gulf of Mexico, Brazil and Africa—the expectation to find large reservoirs by drilling in deeper water is positive.

While the reward can be extraordinary, increased drilling activity in deeper waters can be challenging because of increased safety requirements and an inexperienced offshore workforce. Subsea safety systems and extensive training programs can help overcome these obstacles.

Recent offshore incidents in the Gulf of Mexico and Brazil spotlighted the need for more stringent offshore safety requirements. Governments are imposing large fines on oil companies that breach regulations and are preventing drilling operations. Safety systems are needed to reduce these risks. Organizations such as the American Petroleum Institute (API) and the International Organization of Standardization (ISO) are establishing standards for the design and qualification of subsea safety products, providing third-party credibility.

Although a one-size-fits-all industry standard is not available, individual companies set their own requirements and decide with what standards safety systems must comply. Going through API or ISO provides credibility and shows clients that subsea safety equipment is qualified and meets high standards.

Variations of standards and challenges are the result of well conditions and areas of deployment. Rigs in the Gulf of Mexico must deal with hurricanes, which can shut down operations and cause operators to move the rig off location. Volatile weather in the North Sea makes drilling and completion operations particularly hazardous because of rig movements. Brazil and Africa tend to have calmer waters.

What has been labeled as “the crew change” has also become a serious industry concern. The oil bust of the 1980s and subsequent peaks and troughs help explain the demographic shift in the industry. As crude oil prices plummeted, companies laid off workers and, often, stopped hiring.

However, these layoffs and hiring freezes left an age gap in the industry’s workforce. Oilfield workers are now retiring in large numbers, leaving their tasks to a younger, less-experienced generation. Operators should look for a subsea safety company that has highly trained, multi-disciplinary staff allocated to project delivery and execution as required.

Reliable Subsea Solutions

A subsea safety system’s main objective is to allow hydrocarbons to flow safely. This enables oil companies to obtain valuable information for field development and complete or intervene in wells prior to production. In emergency situations, a subsea safety system needs to quickly and safely stop the flow of hydrocarbons and disconnect at the seabed, allowing the rig to move to a safe location. In general, subsea safety systems are similar. Some examples are:

• Subsea test tree (SSTT)—provides well isolation and a disconnect point at the seabed

• Retainer valve (RV)—enables the isolation of the landing string upon disconnect

• Control system—provides the disconnect time for the type of operation. Control systems used can depend on water depth, rig, local legislation and client preference.

Every project’s needs are different. Operators look for systems that respond quickly and safely to emergency situations and that offer commercial benefits, such as rig time savings or improved production. Smaller service companies have more room for flexibility, providing operators with the advantage of custom tailoring their tools based on the company’s individual needs.

With the continuous development of downhole completions and subsea infrastructures to accommodate deepwater production, developing a range of subsea safety tools for well operations is important to cater to evolving market needs. These tools provide well control functions and disconnect capabilities during well installation, workover, intervention and well test operations. The landing string assembly is a critical component in the protection and safety of personnel, the well and the rig. It also provides the capability for safe, low-cost well re-entry for future well intervention and workover.

Highly trained personnel are necessary for safe operation. In-depth awareness of a client’s requirements and needs means that subsea staff can provide effective technical solutions to ensure that deepwater well installation, workover and intervention are cost effective and timely.

Operational feedback is a critical aspect to improve the industry’s understanding of system integrity and reliability and help eliminate failures that lead to unnecessary downtime. With deepwater operational costs at approximately $1 million per day, avoiding downtime is required to minimize costs. System monitoring and equipment tracking is becoming the standard, enabling operators to better understand the海底 while preventing failures.

Subsea safety companies place great emphasis on safety performance. They want to deliver high standards in the industry and are looking for ways to develop tools that can continuously improve operation safety and enhance the commercial viability of subsea developments.

Subsea Market Future

Subsea is a long-term and high-growth market with demand set to increase in developing and mature locations. For years, activity in the North Sea was expected to decline. However, a shift from major oil companies to smaller independent operators has kept activity high. Deepwater areas in the Gulf of Mexico, South and West Africa, Asia Pacific, and frontier areas within Europe continue to be focal points. Subsea safety companies continue to invest in product lines around the world to meet customer demands.

石油圈

石油圈