想知道近几年的测井、储层评价技术新进展?看这里就对了。

来自 | World Oil

编译 | 周诗雨 郑斯赫

阅读“测井&储层评价技术新进展——随钻测井篇”请点击。

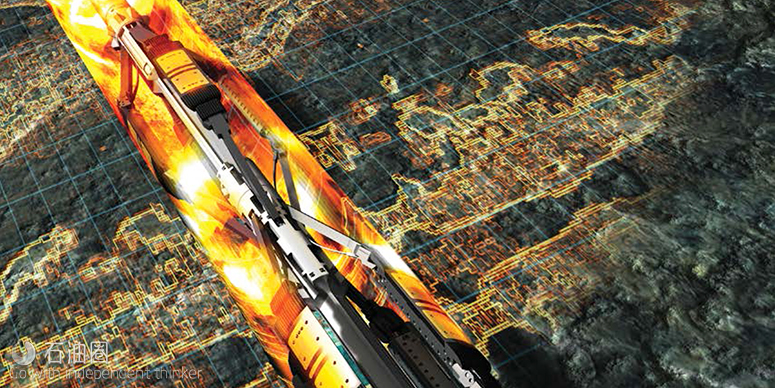

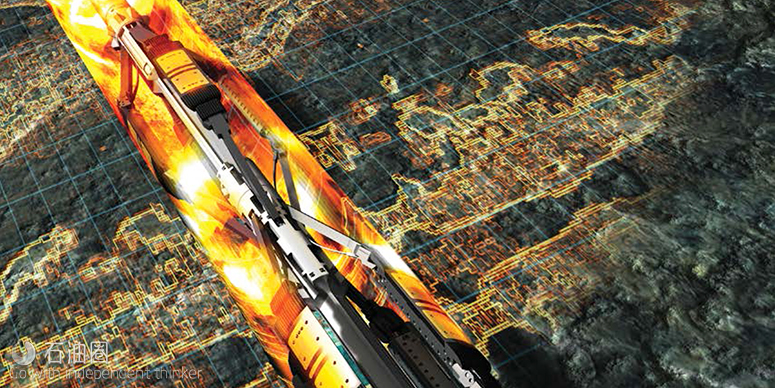

Tractor Conveyance.在大斜度井和水平井中,爬行器可有效替代LWD和钻具传输测井工具。斯伦贝谢的全地形电缆爬行器(UltraTRAC)是一款3-3/8英寸、轮式驱动的装置,有主动牵引力控制系统和双向爬行的功能。UltraTRAC采用了模块化的设计,可安装在七芯或单芯电缆上,配置有2至8个驱动器,每个驱动器可提供高达400磅力的拉力。针对不同的井型和井况,UltraTRAC可对轮子尺寸/形态进行优化设计。工具伸展臂打开后长度可达15英寸,可适应不同的井眼几何形态和冲蚀形态。利用串联短节,UltraTRAC可从地面独立控制短节上方和下方的驱动设备,这种控制方式可以帮助工具顺利通过缩径和冲蚀部位。

声波测井:近井成像。贝克休斯已经将偶极子剪切波反射成像(DSWI)应用到被盐性地层环绕的慢速地层中。该技术可对复杂的近井构造特征和层边界进行造像。利用偶极子源产生的低频压缩体波,深层压缩波成像可进行声波采集、处理以及3D可视化,可增加探测深度,能够对井眼周围深达100英尺处的裂缝和结构特征进行造像,同时能够改善衰减效应。新技术与电阻率测井、井眼成像和VSP配合使用可以丰富井眼周围结构成像的细节。

井眼成像。埃克森美孚公司研发了一种新型自动倾角检测方法。在水平井、大斜度井中,只要倾角测量仪和极板类成像工具获得了相关图像,这种方法就可以确定地层倾角。测试步骤主要是三步:1)使用最小方差法确定每个深度上图像的最优正弦趋势;2)沿梯度图像中的最优正弦线,计算每个深度处的对比度:3)在对比度最高的深度处确定层面边界。这种方法大大缩短了解释时间(最多可缩短80%)。岩石物理评价进行测井工具响应建模时,也能降低建立地球模型时倾角的不确定性。

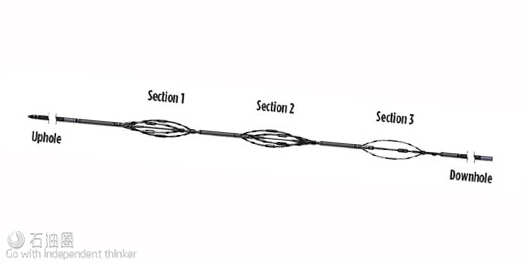

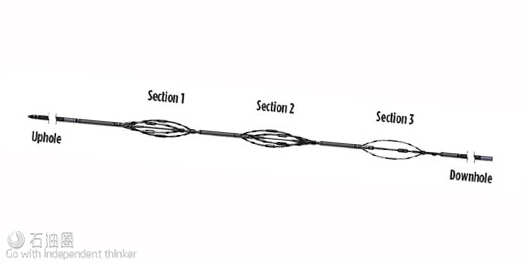

小直径全井眼显微成像工具。为获取非常规油藏分支井中的高分辨率图像,斯伦贝谢公司推出了一款全覆盖、过钻头的小尺寸成像工具。这款工具的尺寸是2-1/8英寸,具有三段测量组件,每段测量组件的弓式扶正器臂上都有四个极板、两个独立的井径仪,如图3所示。每个极板都有两排电子按钮,每排6个,共计12个测量按钮,每段测量组件共有48个按钮,整个工具共有144个按钮。该工具的分辨率为0.2英寸,在6英寸的井眼中覆盖率为76%,在8英寸的井眼中覆盖率为57%。工具还配有六个井径仪,一个三轴加速度计,能够测量加速度和相对方位,完全兼容其他所有的过钻头测量数据。

图3 一种新型的过钻头微成像工具

核测井。威德福推出了一款新型小直径光谱伽玛测井仪,属于威德福的紧凑型测井设备系列。该工具2-1/4英寸,利用钻杆往复工作以记忆模式运行,不论是否使用电缆均可作业。

伽马射线校准。目前人们正在努力使用不同地方的校准工具,建立全球伽马射线校准设施网络。初步调研结果显示,在荷兰巨石阵研发现场,研究人员利用完全不同的设置获取到了校准数据,利用这些数据可以重建位于科罗拉多州大章克申和澳大利亚阿德莱德的设施的KUTh(钾、铀、钍)等级。

电缆地层测试WFT。壳牌的储层测试小组撰写了几篇有价值的最佳实践类综述文章。文章涵盖了油藏评价中井下流体分析技术的现状和未来趋势——包括利用WFT压力瞬态数据改进渗透率估算方法,以及如何使用WFT获取代表性水样。

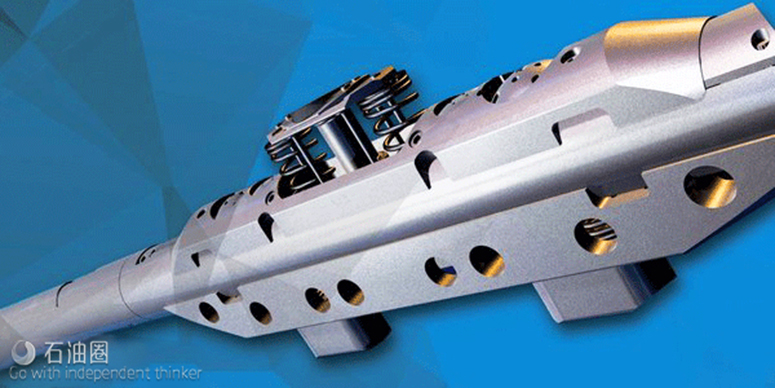

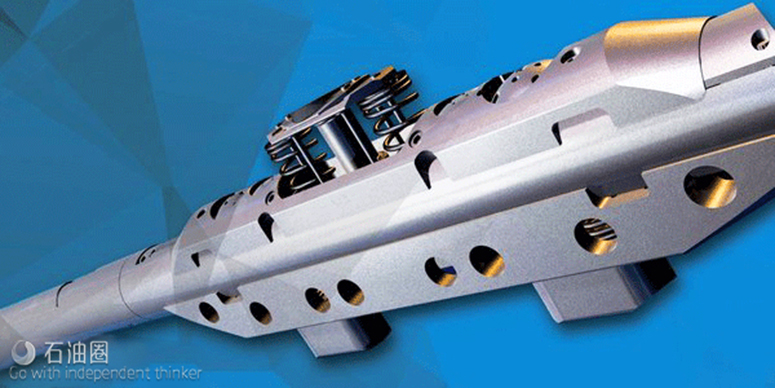

地层压力测试工具。贝克休斯推出了一种先进的电缆地层压力测试服务(FTeX)。FTeX工具为3-7/8英寸,单探头,工作井眼尺寸为4-3/4英寸~16英寸,额定工作温度和压力分别为350℉和30,000psi,如图4所示。该服务能够自动规划井下作业顺序,地面人员只需输入基本的数据就能实现最佳的工具控制和参数测试,从而减少了数据不一致性和误差。闭环系统能够以100次/秒的频率分析压力,然后进行流量微调,优化压降值,保证产量。这种方法可以将流量值控制到0.001立方厘米/秒以下。同时,实时控制技术还能避免增压作用。首次降压产生的压力响应可用于实时计算后续压降值,确定最佳压力值。与类似的工具相比,该工具不仅能够提高数据精度,还能减少作业时间(只需常规工具一半的数据采集时间)。

图4 一种新的压力测试工具

超薄型地层取样器。威德福旗下的紧凑型地层取样器(MFTD)能够获取3个700立方厘米用于PVT分析的地层流体样品,适用于3英寸~14英寸井眼。取样器直径为2.4英寸,采用了自扶正设计,能够降低粘卡风险,可通过电缆或者钻杆下入井内。MFTD获取的实时压力数据可用于计算地层压力梯度,确定流体接触面位置、流体流度和地层渗透率。

阅读“测井&储层评价技术新进展——套管井电缆测井篇”请点击。

OPENHOLE WIRELINE LOGGING

Tractor Conveyance. Tractors provide an efficient alternative to LWD and drillpipe conveyance of logging tools in highly deviated and horizontal wells. Schlumberger’s all-terrain wireline tractor (UltraTRAC) is a 3 3/8-in. wheel-driven device, with active traction control and bidirectional capabilities. It can run on hepta- or monoconductor cable. Its modular design can be configured with 2 to 8 drives, with each unit providing up to 400 lbf of pulling force. Different size/design wheels are optimized for a range of well geometries and conditions. Extended-reach arms are capable of opening to 15 in., allowing the tool to adapt to variations in borehole geometry and washouts. A tandem sub enables independent surface control of the drives above and below the sub. This control helps operators navigate borehole restrictions and washouts.

Acoustic logging: near-well imaging. Baker Hughes has extended the method of dipole shear-wave reflection imaging (DSWI) to imaging complex, near-well structural features and bed boundaries in slow formations surrounding salt-related features. Deep compressional-wave imaging is a new method of acoustic acquisition, processing and 3D visualization that uses low-frequency compressional body waves generated by a dipole source to increase the depth of investigation, thereby allowing imaging of fractures and structural features up to 100 ft away from the borehole with reduced attenuation effects. Integrating the new technology with resistivity logs, borehole imaging, and VSP, can improve the level of detail of structures surrounding the borehole.

Borehole imaging. Exxon Mobil presented a new automatic dip-detection method to identify formation dip in horizontal and high-angle borehole images acquired by any dipmeter and pad-type image tool. It consists of three main steps: 1) determining an optimal sinusoidal trend on the image at each depth using a minimum-variance technique; 2) computing the contrast at each depth along the optimal sinusoidal line on the gradient image; and 3) locating bedding surface boundaries at depths with the highest contrasts. This method has substantially reduced interpretation time (up to 80%) and dip uncertainty in building earth models from image logs for logging tool-response modeling in petrophysical evaluation.

Small-diameter fullbore micro-imaging tool. Schlumberger introduced a slim, full-coverage through-the-bit imaging tool, designed to acquire high-resolution images in lateral wells in unconventional reservoirs. The 2 1/8-in. tool comprises three measurement sections, each having four pads on bowspring centralizer arms that provide two independent calipers. Each pad has two rows of six electrical buttons, totaling 12 measurement buttons, for a total of 48 buttons per section, 144 total. Tool resolution is 0.2 in., and borehole coverage is 76% in 6-in. holes, and 57% in 8-in. holes. The tool provides six caliper measurements, and has a triaxial accelerometer to provide to acceleration and relative bearing, and is fully combinable with all other through-the-bit measurements.

Nuclear logging. Weatherford introduced a new small-diameter, spectral gamma-ray tool as part of its line of compact logging devices. The 2¼-in. tool can be deployed on wireline, or without wireline, in memory mode using a drillpipe shuttle.

Gamma-ray calibration. An effort is underway to establish a worldwide network of gamma-ray calibration facilities by using tools that have been calibrated at different facilities. Preliminary investigations show it is possible to reconstruct the KUTh grades at facilities in Grand Junction, Colo. and in Adelaide, Australia, using calibration data taken at a completely different setup in the Stonehenge R&D site in The Netherlands.34

Wireline formation testing. Shell’s formation-testing group authored several valuable best practices review papers. They cover the current state and future trends in downhole fluid analysis for reservoir evaluation, on methods for obtaining improved permeability estimates from WFT pressure transient data, and how to obtain representative water samples using WFT.

Pressure tester. Baker Hughes introduced an advanced wireline formation pressure testing service (FTeX). The 3 7/8-in. single-probe tool can operate in borehole sizes ranging from 4¾-in. to 16 in. and is rated to 350℉ and 30,000 psi, Fig 5. The service automates the operational sequence downhole to optimize tool controls and test parameters with minimal input from surface personnel, thereby reducing data inconsistencies and inaccuracies. The closed-loop system analyzes the pressure 100 times/sec, making micro-adjustments to the flowrate to optimize the pressure drop, while making sure to remove enough fluid. This allows the flowrate to go as low as 0.001 cm3/sec. Real-time control is used to eliminate supercharging. The formation response from the first drawdown is used to define a behavior for subsequent drawdowns in real time—this allows the service to determine optimal pressure measurements, leading to increased data accuracy and data acquisition in half the time required by similar tools.

Slim-profile formation sampler. Weatherford’s compact formation sampler (MFTD) can acquire up to three 700-cm3 formation-fluid samples for PVT analysis, in borehole sizes ranging from under 3 in. to 14 in. The 2.4-in. diameter tool employs a self-centering design to reduce the risk of sticking, and it enables deployment on wireline or through drill pipe. Realtime and recorded pressure data acquired by the sampler can be used to calculate formation-pressure gradients, ascertain fluid-contact levels, determine fluid mobility, and define formation permeability.

未经允许,不得转载本站任何文章:

-

- 白矾

-

石油圈认证作者

- 毕业于中国石油大学(华东),油气井工程硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。

石油圈

石油圈