As shale and tight reservoir exploration and production continues to grow, oil and gas companies report a discrepancy between predicted long-term production and observed production. This variation prompts questions about the economic viability of these types of reservoirs.

Every shale and tight reservoir is different because each has a unique deposition and burial history. The geologic history of these reservoirs created environments with heterogeneous attributes where the differences impact drilling and completion execution and, ultimately, well performance; these differences have been observed, documented, and have puzzled the industry. The one constant in shale and tight reservoir exploitation is the need to hydraulically fracture the reservoir to obtain economical production rates. Extending wellbore lateral lengths and increasing fracture stage count has resulted in a lower cost per hydrocarbon molecule produced.

Conventional fracturing designs are insufficient for these unconventional reservoirs. The placement and length of the horizontal wellbore influence how and where to fracture the rock. Wellbores in a long “sweet spot” can be fractured along the wellbore. The more likely scenario is a wellbore that contacts multiple “sweet spots” with intervals of unfavorable rock in between calling for multiple fractures. Fracture treatments can contribute up to 75 percent of the total well cost. Knowing where to target and how to perform fracture treatments saves costs and may sustain higher short- and long-term production.

Maximizing production and minimizing well costs require successful fracturing made possible by precisely placed, properly completed, and effectively stimulated wells.

Close collaboration between the operator and the service company to reach a unified solution is also a necessity in unconventional resource development. The variability of the reservoir often leads to differences in opinions among the multiple disciplines involved. When disciplines work separately, the disconnect causes process inefficiencies with respect to time and accuracy and negatively impacts decision-making.

The tailored approach of the Halliburton CYPHERSM Seismic-to-Stimulation Service delivers enhanced profitability to our customers in shale and tight reservoirs. The CYPHERSM service achieves this through basin knowledge, accurate geoscience analysis coupled with precision engineering, operational experience, the continuous capture and application of lessons learned and model validation using actual well performance data.

The service impacts economics, challenges, and the learning curves associated with shale and tight reservoir development. Economics are improved by optimizing well placement, completion, and stimulation treatments. Challenges are solved using new modeling tools designed specifically for these reservoirs. Learning curves for drilling and completing these wells are reduced by eliminating “trial and error” field development using integrated workflows designed and tested with Halliburton’s reservoir understanding, experience, and proven processes.

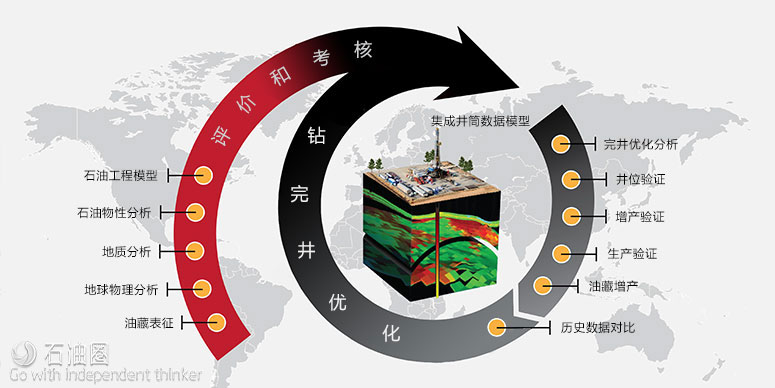

The CYPHER service workflow is built around an integrated data center that incorporates all processes performed through the life of an asset. Using CYPHER service, geoscience modeling elevates reservoir knowledge and benefits drilling and completion processes to help with crucial elements including optimizing wellbore placement and effective stimulation. The centralized data and integration increases the efficiency of work performed by an asset team and, in turn, helps reduce the risk associated with completions and boosts overall asset profitability.

The CYPHER service helps asset managers and senior management to:

1.Maximize asset value:

—Increase total recoverable reserves;

—Enhance production rate.

2.Enhance the use of geoscience data;

3.Drive surface and subsurface efficiencies.

The CYPHER service provides a collaborative partnership between an experienced Halliburton multidisciplinary team and our customer for the life of the asset. Through collaboration, the service identifies key reservoir attributes to enable drilling and stimulating the best wells first. The partnership enables data integration across multiple platforms to create and maintain an Integrated Asset Model which is key to optimizing shale and tight reservoirs at the asset level.

The CYPHER service is supported by new modeling tools specific for shale and tight reservoirs. After careful analysis of the characteristics of these reservoirs and how they relate to each other and how they affect production, new software was developed to integrate the analyses of the characteristics by multiple disciplines.

The CYPHER service delivers a systematic learning methodology to help minimize risk and uncertainty and to increase knowledge with each update of the Integrated Asset Model.

Detailed analysis

The Integrated Asset Model is a product of the analysis and modeling of the asset and contains all the geological, mechanical, and petrophysical properties necessary to understand the asset. The CYPHER service team performs petroleum systems analysis, field planning, and geophysical analysis to create earth models and reservoir simulations. If production data is available, complex fracture models are also built.

Full-field planning

The analysis and modeling determines the “sweet spots” for the asset. With this knowledge, field planning begins to identify well numbers, location, spacing, and lateral length. Because each asset is different, the CYPHER service team tailors the field designs to the needs of each customer. Some customers will benefit from more wells strategically placed, and others will benefit from less. The same is true for other well features.

Well planning and drilling execution

The drilling program uses the “sweet spots” to set well targets and designs to hit those targets. When a well is ready to be drilled, the operational team ensures the well is placed in-zone and the wellbore is stable using real-time data monitoring. The completion design is directly dependent on the placement of the well. No amount of fracturing will help production if the wellbore is out of the “sweet spot.” Real-time data collected during drilling and formation evaluation are added to the models and then simulations are performed with the new data to remove uncertainty and to validate current designs.

Completion design

With the wellbore in-place, the CYPHER service team and the customer design the completion program. This includes the number of fracture treatments and spacing, fracture length and height, and their location along the wellbore. Optimized completion ensures only the best zones are fractured to reduce costs and reduce the risk of damaging the reservoir and surrounding geography. Completion data is monitored and collected to improve the models and simulations.

Production validation

The CYPHER service team uses a minimum of the first 90 days of production data (determined by initial field/well performance) to perform history matching and to validate the expected production matches the actual production.

CYPHER service validation

With all the data from one or more wells and with data coming in from each new well in the asset, the CYPHER service team validates the analysis and execution provided by the service, calibrates all models with the latest data, and updates any designs affected by the new data. Through continual field development improvement, costs are reduced and profits increased for these highly challenging reservoirs.

Customers have found that conventional techniques fall short of expected results while producing unconventional shale and tight reservoirs. Using efficient workflows that promote collaboration between Halliburton and the customer, and supported by an extensive global unconventional shale and tight reservoir database, the Integrated Asset Model is developed to support profitable engineering decisions that help improve efficiency, productivity, and the overall value of shale and tight reservoir developments.

石油圈

石油圈