Tension leg platforms (TLPs) have been recognized by their favorable response especially in the heave, roll and pitch degrees of freedom and therefore are ideal platforms to support top tensioned risers (TTRs) in harsh environments. TLPs are also the most suitable platforms to support steel catenary risers (SCRs) in relatively shallow water (600 to 1,200 m/1,968 to 3,937 ft). They offer large ventilated deck area and can be fully integrated at quayside. However, the industry has always been under the assumption that the TLP feasibility beyond 1,600 to 1,800 m (5,249 to 5,905 ft) cannot be established due to the challenges associated with the tendon design in these deepwater depths.

The goal here is to challenge that assumption, since a TLP’s limit is not just a function of water depth, but also a function of displacement (hence payload) and environmental conditions.

TLP applications

TLPs have been widely used in wet and dry tree applications in the oil and gas industry in water depths from 100 m to about 1,500 m (328 ft to 4,921 ft). The TTRs have their advantages in allowing direct vertical access to production wells.

However, due to tensioner stroke limitation, the use of TTRs requires a floating system that provides minimal heave response. The industry has been under the assumption that in water-depths beyond about 1,828 m (6,000 ft), the TLP tendon design becomes impractical and the TLP feasibility cannot be established.

However, it has been demonstrated that manufacturer can supply tendon pipe with up to 1.7-in. wall thickness. A pipe with this wall thickness can easily withstand hydrostatic pressure in even 2,800 m water depth if the pipe OD is relatively small. The true limit to application of a TLP is therefore the required heave and roll/pitch natural periods (typically less than 4.0 sec) that need to be achieved in order to avoid undesirable TLP dynamic response. Since

natural period is a function of mass and stiffness, the limitation on TLP application is an envelope as a function of TLP displacement (or payload), water depth and environment (or location). But as will be seen, the simplistic assumption on water-depth limitation of TLP applications can be challenged.

TLP designs in the GoM

TLPs carrying topsides payloads of 53,491 mt (large), 32,176 mt (mid) and 7,573 mt (small) located in the central area of the GoM were examined in this study. The water depth is then varied in an iterative process to achieve feasible solution for each of the three designs. The feasibility criteria include:

1.The pre-service draft for float on/off a heavy-lift vessel;

2.The maximum platform width to satisfy most of the shipyards dry dock dimensions;

3.Tendon in-water weight in the freestanding conditions <228 mt (500 kips);

4.Tendon wall-thickness should not exceed the current manufacturing capability; Wt<43.2 mm (1.7 in.);

5.Platform heave and roll/pitch natural periods should not exceed 4.7 and 4.0 sec, respectively;

6.Tendon utilization ratio and interaction ratios should be <1.0 to meet the code check (API RP 2T are adopted for this purpose);

7.Positive airgap in 1,000-year conditions;

8.Maximum offset should not exceed 13% of the water depth in 1,000-year survival conditions.

It is assumed that the maximum number of tendons that can be hung from the TLP is 16. This is a reasonable practical limit on the number of tendons due to the space available for the tendon porches on the TLP hull, as well as tendon pre-installation considerations. Conventional hull form with four vertical circular columns and a ring pontoon disposed at the lower end of the columns were assumed in this study.

WAMIT software (MIT), along with in-house tools, were used to perform global performance and tendon analyses of the three TLP designs. The tendon tension RAOs and the key design data for these designs were examined as well. All of the design parameters were within the feasible limits.

It was found that feasible solutions at water depths of 1,052 m (3,451 ft), 1,692 m (5,551 ft), and 2,408 m (7,900 ft) could be established for TLPs with topside payloads of 53,491 mt, 32,176 mt and 7,573 mt, respectively. Therefore, a TLP with conventional tendons is feasible in almost 8,000 ft (2,438 m) water depth in central GoM harsh environment, provided that the payload is limited to about 8,000 mt.

TLP designs in West Africa

The above exercise was repeated for TLPs located offshore West Africa. TLPs carrying topsides payloads of 58,000 mt (large), 39,500 mt (mid), and 9,500 mt (small) located offshore West Africa were assumed for this study.

The water depth was again varied in an iterative process to achieve feasible solution for each of the three designs. Similar feasibility criteria as those used in the GoM TLP designs were again adopted. Once again, the tendon tension RAOs and the key design data for these designs were found to be within the feasible limits.

Feasible solutions at water depths of 1,219 m (4,000 ft), 1,829 m (6,000 ft), and 2,743 m (9,000 ft) were established for TLPs with topside payloads of 59,000 mt, 39,500 mt, and 9,500 mt, respectively. Therefore, a TLP with conventional tendons is feasible in 9,000 ft (2,743 m) water depth in the West Africa environment, provided that the payload is limited to about 9,500 mt.

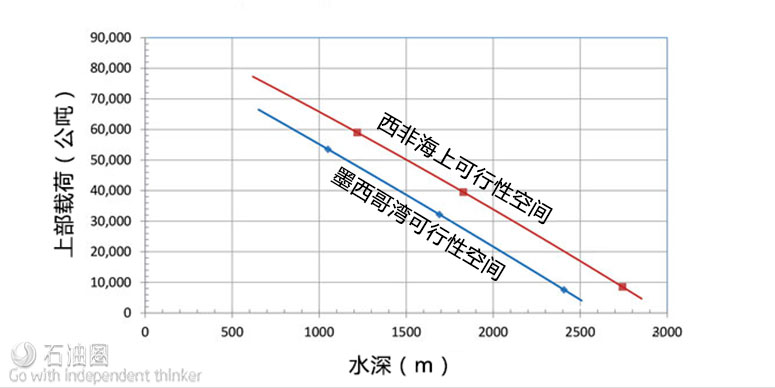

Feasibility envelopes

The feasibility envelopes for TLPs in the Central GoM and offshore West of Africa were established based on the case studies discussed above. The study investigated these feasibility envelopes as function of topsides payload, water depth, and environmental criteria (defined by the design region). As can be seen, a TLP with conventional tendons can be feasible even beyond 2,800 m (9,186 ft), depending on the payload and the environment.

For very large payload at relatively shallow water in the GoM, the TLP design is dominated by tendon utilization. In the intermediate water depth with medium payload, tendon utilization, natural periods (governed by both mass and stiffness) and tendon in water weight are the controlling parameters. The design in ultra-deepwater with small payload is also found to be dominated by the tendon utilization, natural period and the tendon in-water weight.

For TLPs offshore West Africa, the TLP design with large payload and relatively shallow water is mainly dominated by the natural period requirements. Natural periods, tendon IR utilization, and tendon in-water weight are still dominating the TLP design in the intermediate water-depth with medium payloads and the ultra-deep water designs.

TLPs offshore West of Africa have larger feasibility limits compared to the GoM due to the more benign environment. The feasibility envelopes are found to be almost linear for both West Africa and the GoM regions. It has to be noted that these feasibility envelopes could shift up or down depending on the applied feasibility criteria.

Alternative tendon design

The industry has been searching for alternative nonconventional tendon designs that would expand the TLP feasibility limits with conventional tendons.

One of the designs that can be discussed here is the cellular tendons. This design has the same main components as a conventional tendon, i.e., a tendon top segment (TTS) that interfaces with the platform; a tendon bottom segment (TBS) that connects to the tendon foundation at the seafloor; and a main body that links the two through the water column. The cellular tendon innovation resides in the design of the main body. Instead of one pipe, it consists of multiple metallic tubules. It also has an upper transition unit to interface with the TTS and a bottom transition unit to interface with the TBS. The top and bottom interfaces, TTS and TBS, are kept the same as in conventional tendons. The same tension-monitoring units in the conventional tendons can be used in the cellular tendons as well.

Two types of cellular tendons were investigated – full and hybrid cellular tendons. The full cellular tendon design uses cellular tendon technology along the entire length of its main body segment. In this case no tendon couplings are used, and the full length of the tendon is fabricated in the yard, towed to the installation site where the tendons are upended and installed.

Whereas, in the hybrid cellular tendon design, only part of the tendon main body segment uses the cellular tendon technology and the remaining part stays as conventional tendons. The length of each main body segment (cellular or conventional) is limited to less than 90 m (295 ft), and couplings are used to connect the main body segments, just as in the conventional design.

The cellular tendon technology through its multiple bundled tubes enables the designer to achieve larger total cross sectional area through the use of smaller diameter individual tendon pipes with reasonable wall thickness that solves the issues associated with the utilization ratios at top and the interaction ratios at bottom.

Through this larger area, cellular tendons also offer larger tendon stiffness that controls the TLP natural periods below the desired limits of 4.7 and 4.0 in heave and roll/pitch directions, respectively, at deeper water depths compared to the case studies considered in this study.

Synthetic foam pieces enclosed by the pipe bundles can reduce the tendon in-water weight which appeared to be one of the controlling design parameters in the conventional design. Preliminary analysis shows that the use of cellular tendons can push the feasibility water depth limit by 40% deeper.

Conclusion

TLP application limitation is not a function of water depth alone. Rather, it is a function of TLP payload, water depth, and design environment. Several case studies were prepared where TLPs supporting incremental increase in payloads and located at deep and ultra-deep waters in different areas of the world were examined. TLPs located in the Gulf of Mexico and offshore West Africa were designed, and feasibility envelopes as a function of payload, water depth, and location were then established accordingly.

The study found that TLPs with conventional tendons can be feasible even beyond 2,800 m, depending on the topside payloads and the environment. On the other hand, for TLPs with large payload, the water depth limit may be even lower than the conventional standard of about 1,500 m.

For very large payload at relatively shallow water in the GoM, the TLP design is dominated by tendon utilization, while for medium payload at intermediate water depth, natural periods (governed by both mass and stiffness) and tendon in water weight appeared as additional controlling parameters. The design in ultra-deepwater with small payload is also found to be dominated by the tendon utilization, natural period, and the tendon in-water weight.

For TLPs offshore West Africa, the TLP design with large payload and relatively shallow water is mainly dominated by the natural period requirements. Natural periods, tendon IR utilization, and tendon in-water weight are still dominating the design in the intermediate water depth, with medium payloads and the ultra-deepwater designs.

TLPs offshore West Africa have larger feasibility limits compared to the GoM, due to the more benign environment. The feasibility envelopes are found to be almost linear for both West Africa and the GoM.

The alternative cellular tendon technology, through its multiple bundled tubes, enables the designer to achieve the desired larger total cross sectional area. This is done through the use of smaller diameter individual pipes with reasonable wall thickness. This solves the issues associated with the utilization ratios at top and the interaction ratios at bottom associated with the conventional tendon designs.

Through its larger cross section area, cellular tendons also offer larger stiffness that controls the TLP natural periods below the desired limits of 4.7 and 4.0 for in heave and roll/pitch directions, respectively, at deeper water depths compared to the case studies considered here with the conventional tendons. Synthetic foam pieces enclosed by the pipe bundles can reduce the tendon in-water weight which appeared to be one of the controlling design parameters in the conventional design. Preliminary analysis shows that the use of cellular tendons can push the feasibility water depth limit by 40% deeper for the same payload and environment.

石油圈

石油圈