NOV推出的Tektonic系列钻头平台融合了一系列创新的钻头设计技术成果,能够从钻头设计开始为运营商定制钻头,每一个钻头都是量身定制的,能够有效克服特定环境的困难,满足特定需求,提高钻井效率。

来自 | NOV

编译 | 张玉亭

NOV于2016年1月发布了该公司研发的Tektonic™钻头平台,该平台能够尽可能地提高钻进速度(ROP)、钻头稳定性以及切削结构的耐用性,进而有效提高钻头/岩石界面的钻进效率。

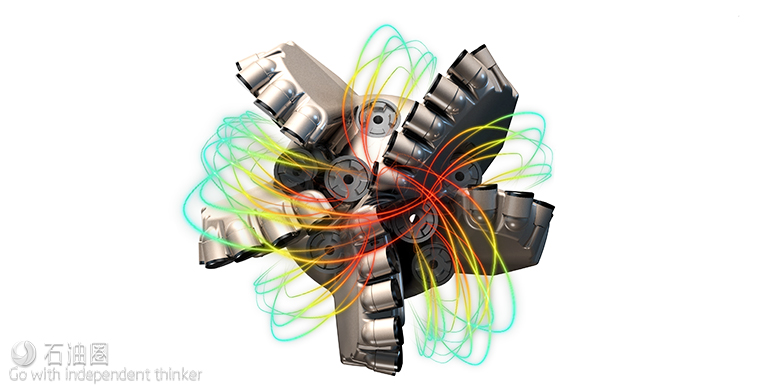

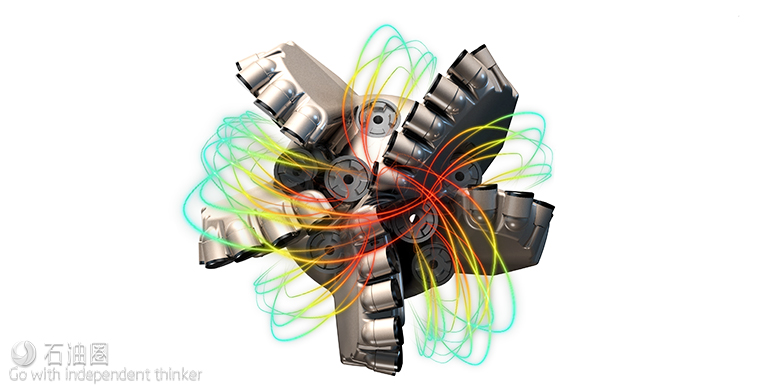

用于Tektonic钻头平台开发的ReedHycalog™平台融合了齿端钻头的几何轮廓结构设计、加强型切削齿分布布局设计(采用优异的水力学设计)以及新一代的PDC镜面切削齿技术等一系列创新技术成果,利用该平台开发的钻头产品能够有效提升严苛钻井环境下的钻井效率。在提供优异的区域工程支持服务的同时,NOV的区域设计工程师团队还能够利用该平台提高钻头设计服务的效率,并可根据实际情况量身定制满足特定应用需求的钻头产品。

核心技术

1.新一代镜面加工切削齿—Reflektor切削齿具有圆滑的表面,能够有效降低钻头泥包风险,提高钻进速度。

2.增加了沿钻头冠部分布的切削结构剖面长度,能够有效提高钻屑的清除效率,降低了破碎岩石的能量需求。

3.优化了螺旋布齿带,能够有效降低切削齿与岩石之间相互作用产生的局部围压。螺旋角保持在最低水平以最大限度地缓解螺旋结构设计中常见的水力损失问题。

4.NOV的动态旋转钻头模拟专利软件能够精确模拟偏心钻头在井底的运动特征,从而对切削齿载荷、工作效率以及磨损特征进行分析优化。

5.NOV在流体流动模拟方面取得了显著进展,能够实现对切削齿面的流体剪切应力、横向流动状态以及岩屑量的模拟检测,进而能够对新钻头设计方案的岩屑清除效率和冷却性能进行量化评估和优化。

ReedHycalog平台可以提供量身定制的Tektonic钻头产品服务,以满足特定的应用需求。工程师可根据现场实际情况调整钻头金刚石和基质的化学成分,对钻头的耐温性、抗磨性以及抗冲击性进行优化提升。与常规未经过抛光处理的PDC切削齿相比,Reflektor切削齿前缘经过抛光处理,能够有效降低钻头与地层岩石之间产生的摩阻,从而能够有效提高钻进速度并降低机械比能。这一效果已在现场应用中得到了证实,并在不同岩石类型的实际地层中进行了量化分析。

目前,Tektonic标准钻头设计流程已经引入了经过改进后的数值分析工具和程序,从而进一步提高了针对特定产品需求进行设计的能力,能够针对多种非对称旋转的工况(包括使用弯曲壳体定向钻井马达以及旋转导向钻井工具系统进行钻进的工况)开展切削齿与岩石的相互作用的力学模拟分析,可根据不同的驱动系统和井下工具几何形状,对切削齿上的应力分布、钻头磨损情况以及钻头与复杂几何形状井眼之间的相互作用等进行优化调整,从而为用户提供不同的切削结构设计方案。

此外,改进后的数值分析软件采用了新的计算流体动力学理论,并通过了加压钻井试验的验证,在不过度磨损钻头体的情况下,即可优化调整切削结构的清洗和冷却效果。

研发团队经过多年努力终于在初期的钻头实验中取得了令人鼓舞的研究结果,取得初步成功之后,研发团队又针对现场情况对多种钻头设计方案进行了最终的现场测试。测试钻头在不同国家和地区(包括美国、阿曼、伊拉克和中国)的多种不同地层中(包括页岩地层、灰岩地层以及多岩性交互地层)进行了应用并取得了成功,所有测试钻头的性能都超过了竞争对手的同类产品,钻进速度比常规钻头的平均钻进速度提高了24%~108%。

总结认为,对计算机辅助模拟分析技术、PDC切削齿选择技术、室内测试以及现场测试等多种技术手段的综合协调应用是取得上述成功的关键因素。上述高性能钻头在未来的应用中具备为作业者进一步降低钻井成本的潜力。

案例分析Ⅰ:中东

自NOV推出Tektonic系列钻头产品服务之后,中东地区的作业者使用Tektonic平台取得了一系列ROP记录。

2016年第一季度,中东地区某运营商使用了配备16mm直径Reflektor切削齿的六刀翼TK66 Tektonic刚体钻头,进行了12-1/4”井段的钻进作业。该钻头一趟成功钻过了2480m厚的复杂地层(包含了极具挑战性的灰岩、白云岩、泥页岩以及高研磨性的砂岩层段),性能远远超过了之前已成为该层段钻进作业标配的胎体钻头。同时,该钻头还创造了该层段23.4m/h的现场作业记录,比平均钻速提高了63%。

2015年第四季度,中东地区某运营商使用12-1/4”的TK59 Tektonic钻头钻进某个极其敏感的地层,成功完成了垂直井段的钻进作业,到达靶点深度,与竞争对手在类似岩性地层中的作业效果相比,Tektonic钻头的单趟钻井进尺提高了13%,钻进速度提高了53%。

2015年第四季度,中东地区某运营商使用配备16mm直径Reflektor切削齿的六刀翼TK66 Tektonic胎体钻头钻进了8-3/8”井段,利用单个钻头以11.5m/h的钻进速度钻过了1397m的地层,成功钻达完钻井深,钻进速度与之前的最高纪录相比提高了11%,作业效果评级为1-1-WT-A-X-I-NO-TD。

Tektonic钻头在中东地区一些极具挑战性的地层钻进过程中取得了不错的应用效果,能够帮助作业者在提高钻井效率的同时降低钻井成本。

案例分析Ⅱ:美国Delaware盆地

Tektonic TK76钻头最近在新墨西哥州莱亚郡协助创造了两项作业记录,帮助作业者在Delaware盆地创造了7000f长、9.875”井段地层的最快钻进记录。

2016年第二季度,该地区某运营商使用一个配备Permian系列切削齿的TK76钻头完成了莱亚郡一口井直井段的钻进作业,该钻头用时43.5h钻过了长度为7731ft的地层,平均钻进速度达到了177.7ft/h(54.2m/h),比该地区平均钻进速度提高了97%。

2016年第三季度,该地区某作业者使用相同钻头用时37.5h钻过了长度为7032ft的地层,平均钻速达到了187.5ft/h(57.2m/h),创造了Delaware盆地7000ft进尺以上的单趟最快钻速记录,比该地区平均钻进速度提高了104%,与前十名作业服务公司相比,钻进速度提高了32%。

Launched in January 2016, the Tektonic™ drill bit platform from NOV increases drilling efficiency at the cutter/rock interface, maximizing rate of penetration, stability, and cutting structure durability.

ReedHycalog™ Tektonic™ drill bit platform fuses cutting-edge bit body geometry, enhanced cutter layout coupled with superior hydraulic design methods, and the next generation of PDC mirrored cutter technology to boost drilling efficiency in your most challenging drilling environments. Offering unparalleled localized engineering support, our Regional Design Engineers (RDE) are equipped to design these bits more efficiently and provide bits specifically tailored for your application needs.

Core Components:

• Next-generation mirror finish cutter technology, Reflektor™ cutters, improve drilling proficiency with a sleek surface that reduces bit balling and increases ROP.

• Incremented cut profile along the blade creates a more efficient path for cuttings removal, and reduces the amount of energy required to fail the rock.

• Optimized blade spiral reduces localized confinement pressures at the cutter rock interaction; spirals are kept to a minimum to avoid the reduced hydraulics efficiency seen on many spiral designs.

• Cutter loading, work rates, and wear characteristics are optimized using our proprietary dynamic rotation bit modeling sofware, which accurately models eccentric bit motion conditions downhole.

• Advancements in fluid flow modeling quantify and improve hydraulic cleaning and cooling performance for all new designs, by examining cutter face fluid shear stress, cross-flow mitigation, and cuttings volume.

Tektonic™ drill bits are customized to overcome specific application requirements. Engineers formulated advanced diamond and substrate chemistries to increase thermal, abrasion, and impact resistance as a function of application demands. The polished front face of Reflektor™ cutters allows lower friction, higher rates of penetration, and lower mechanical specific energy compared to unpolished PDC cutters. This effect has been observed and quantified in multiple rock types in real-life applications. Improved numerical modeling tools and procedures are implemented into the Tektonic standard design process to enhance designs for specific applications. Cutter-rock interaction forces are now modeled based on a variety of non-symmetric rotation scenarios including bent housing motor with drill string rotation and specific rotary steerable tool systems. This process provides a cutting structure customized to specific drive system and bottom hole assembly geometries to improve force distribution, localized wear, and interaction between the bit body and complex bottom hole shapes. New computational fluid dynamics guidelines are supported through validation via pressurized drilling laboratory facilities and allow for optimized cleaning and cooling of the cutting structure without undue erosion of the bit body.

Several years of research and development led to encouraging results with initial experimental bits, and several designs were deployed to the field for final tests. The bits drilled in a variety of formations, including shales, limestone and interbedded formations in different regions and countries including USA, Oman, Iraq and China. All studied bits outperformed the competition, improving ROP by 24% to 108% compared to the offset average. A comprehensive and collaborative approach that included computer-aided simulation, PDC cutter selection, laboratory tests and field tests paved the path for these successful results. These high performance drill bits have the capacity to further reduce drilling costs for operating companies.

Case study

Tektonic™ drill bit platform breaks records in the Middle East

Operators in the Middle East have achieved record ROP’s since the launch of NOV’s new ReedHycalog™ Tektonic™ drill bits.

In Q1 2016, a major Middle East operator ran a 6 blade, 16mm cutter steel-bodied TK66 Tektonic bit fitted with Reflektor cutters to drill the 12 ¼” section. The bit successfully drilled the entire 2,480m interval in a single run through challenging limestone, dolomite, shale and highly abrasive sandstone formation, outperforming matrix bits which were standard in this section. The bit set a new field record of 23.4m/hr a 63% improvement on the field average.

In Q4 2015, a 12 ¼” TK59 Tektonic bit was run by a major operator through an extremely reactive formation in the Middle East. The bit drilled the vertical section to TD, 13% longer and 53% faster than the competition bit drilling through similar lithologies.

In Q4 2015, a major Middle East operator ran a 6-blade, 16 mm cutter matrix-bodied TK66 Tektonic bit fitted with Reflektor cutters in the 8 ⅜” section, reaching total depth after drilling 1,397 m at a rate of 11.5 m/h. The bit achieved 11% faster ROP than the best offset and was graded 1-1-WT-A-X-I-NO-TD.

Tektonic TK76 Drill Bits Go the Distance in Delaware Basin

Tektonic™ TK76 bits from NOV have contributed to two recent record runs in Lea County, New Mexico, helping operators achieve the fastest 9.875 in. runs over 7,000 ft in the Delaware Basin.

In Q2 2016, an operator used the 9.876 in. TK76 bit with Permian Series cutters to drill the vertical section of a well in Lea County. The bit drilled 7,731 ft in 43.5 hours for an average ROP of 177.7 ft. This run increased ROP by 97% over the Delaware Basin average.

The following quarter, an operator used the same bit to drill an interval of 7,032 ft in 37.5 hours for an average ROP of 187.5 ft/hr. This was the fastest recorded ROP for the Delaware Basin on runs exceeding 7,000 ft. The bit increased ROP by 104% over the Delaware Basin average and 32% over the top ten performers.

未经允许,不得转载本站任何文章:

-

- 白矾

-

石油圈认证作者

- 毕业于中国石油大学(华东),油气井工程硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。

石油圈

石油圈