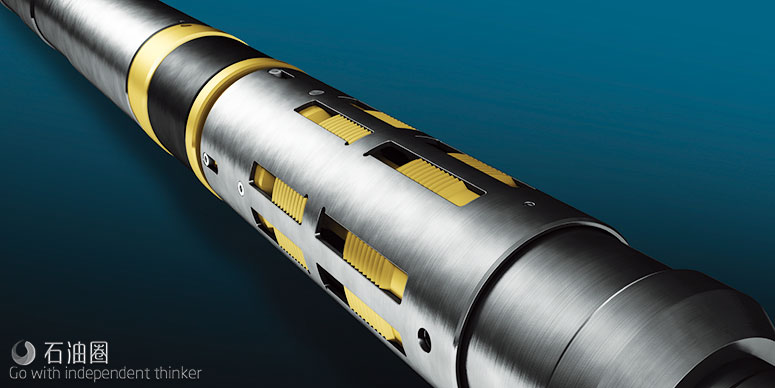

SIMPLUS from Peak Well Systems provides oil and gas companies with a new range of ISO14310 V3 rated plug systems for barrier and flow control applications anywhere in the production tubing.

In a similar approach to Peak’s highly successful SIM System which has seen over 2,000 successful deployments and retrievals worldwide, the new SIMPLUS range of products is also modular. SIMPLUS employs interchangeable components which facilitate a variety of downhole applications such as zonal isolation, wellhead isolation, contingent plugging, straddles and chokes. The large internal diameter (ID) of the SIMPLUS Retrievable Bridge Plug makes this sealing system ideal for modular straddle systems that can improve well performance significantly.

Nigel Avern, Chief Executive of Peak Well Systems, commented: “Comprehensive testing has been successfully performed and subsequently independently verified and certified by Det Norske Veritas Perth.” SIMPLUS Retrievable Bridge Plugs are available in all sizes from 2 7/8” up to a larger 7” size.

“We anticipate considerable demand for SIMPLUS amongst North Sea customers who already specify Peak products in their Flow Control intervention work elsewhere in the world and can now benefit from the same flexibility and reliability in applications that require specific well integrity conformance. Our SIMPLUS products will be made available to customers through our expanding Rental and Service business operations, ensuring that customers benefit from our Peak Field Specialists who are highly trained and experienced in plug system deployments.”

With an established track record in the development and provision of advanced Flow Control technologies, Peak now offers its technical expertise in well barrier applications that require higher-specification well integrity compliance:

1.Zonal Isolation;

2.Wellhead Isolation;

3.Contingent Plugging;

4.Leak Detection;

5.Straddles;

6.Chokes.

The SIMPLUS portfolio employs an ISO14310 V3 rated SIMPLUS Retrievable Bridge Plug that creates a reliable and high performance downhole seal. Its development is the result of extensive R&D, testing and analysis, utilising Peak’s track record and ingenuity in deploying and retrieving reliable plug systems successfully around the world.

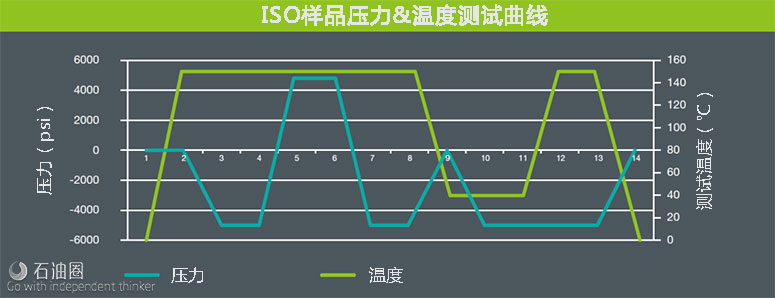

The SIMPLUS Retrievable Bridge Plugs have been independently verified and certified by Det Norske Veritas (DNV) to ISO14310:2008 V3 standard across their full operating range of pressure and temperature (5,000psi or 7,500psi and 150℃/300℉) to provide operators with total assurance and transparency when planning downhole operations.

Quality controls to ISO standards for storage, maintenance and documentation to track performance are also incorporated into the development of SIMPLUS products. This includes:

1.Supply of materials and traceability records (MTR);

2.Heat treatment CoCs; sample dimensional inspection of components;

3.Shear pin/screw material batch testing;

4.Retention of QA/QC documentation.

All SIMPLUS products are modular and interchangeable, and are designed to be set anywhere in the tubing string without the need for a nipple profile. They can be deployed by all conventional conveyance methods. With its advanced setting mechanism, it is the only mechanical-set V3 rated plug available, creating unrivalled operational flexibility and confidence.

SIMPLUS Retrievable Bridge Plugs are available in all standard industry sizes from 2-3/8in up to the larger 7in size. Importantly, it has a large internal diameter (ID) which makes this sealing system ideal for modular straddle applications, leak detection and where flow is restricted. Furthermore, SIMPLUS offers ultimate flexibility to plug and divert flow using uni- and bi-directional flow control devices.

The large internal diameter (ID) of the SIMPLUS Retrievable Bridge Plug makes this sealing system ideal for modular straddle applications, leak detection and where flow is restricted, offering excellent flexibility, high assurance and conformance to the most stringent of well barrier criteria. The SIMPLUS Retrievable Bridge Plug is recovered using a conventional GS Pulling Tool fitted with industry standard Peak Multi-Action Top Sub (MATS) and Pulling Prong.

Quality controls (level 3) for the storage, maintenance and documentation for performance tracking and traceability are incorporated into the development of all SIMPLUS products.

Applications

1.Well suspension during completion, workover & well maintenance;

2.Zonal isolation for leaks, water/gas shut-off or stimulation;

3.Straddle for gas-lift;

4.Downhole choke & inflow control;

5.Packer setting & completion pressure tests;

6.Suspension of downhole gauges.

Features & Benefits

1.ISO 14310:2008 V3 accreditation;

2.Simple to redress in the field minimising NPT;

3.Multiple setting options: mechanically on slickline, eline, coil tubing, drill pipe or tractor;

4.Debris tolerant design to limit ingress;

5.Multiple equalising assembly options (Melon, Prong or Pump-Open type);

6.Ultimate flexibility to plug and divert flow using uni- and bi-directional flow;

7.Operational assurance from high temperature/high pressure sealing element;

8.Sour service components to NACE MR0175 specifications.

All SIMPLUS products can be easily redressed in the field by our Peak Field Specialists, reducing Non Productive Time (NPT) that is inherent with other systems that require to be returned onshore after each run.

石油圈

石油圈