The Baker Hughes UltraConnect? 35K HPHT perforating solution provides consistent, safe, and efficient perforations in wellbores with pressures as high as 35,000 psi (2413 bar) and temperatures up to 470℉ (243℃).

As operators drill increasingly deeper wells, the need for tools to perform reliability in challenging high-pressure, high-temperature (HPHT) conditions becomes more pronounced. Trip times, nonproductive time (NPT), and rig costs put increasing pressure on operators to choose products and services wisely. Baker Hughes designed the UltraConnect perforating solution to stand up to some of the world’s deepest and hottest wells, and to provide effective completions that maximize production potential.

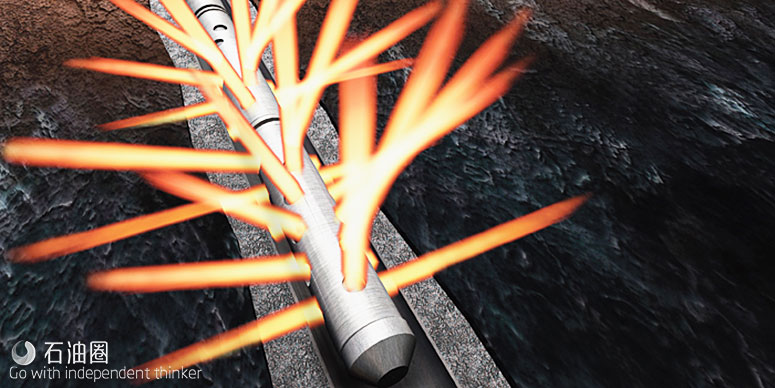

Engineered with field-proven reliability recognized by operators around the world, the UltraConnect perforating system can be tailored to suit almost any HPHT environment and is an integral component in the Baker Hughes line of TCP systems and tools. Combined with our DeepConnect? charges, the UltraConnect perforating system maximizes perforations in hard rock environments and when firing through heavy, high grade casing. Upgraded Baker Hughes Model D? and Model RD? pressure firing heads can also be used with the UltraConnect perforating system to lower applied firing pressures, which can be critical in ultra-deep wells. Even before the job starts, Baker Hughes PulsFrac? software models gun shock and dynamic underbalance effects, enabling the team to build completions plans that effectively deploy the UltraConnect perforating system to maximize reservoir communication—safely and efficiently.

DeepConnect perforating charges are designed specifically for hard rock environments and provide measured performance in heavy-weight, high-grade casing. Testing is carried out in conditions that mimic those of the actual downhole environment, promoting superior reliability during operation.

The Baker Hughes upgraded Models D and RD pressure firing heads enhance the field-proven reliability that operators already recognize. Featuring precision rupture discs instead of shear pins, firing pressures are more accurate, allowing lower applied firing pressures, which is critical in ultra-deep wells.

Incorporating these sleek firing heads into the design of the UltraConnect 35K perforating system maintains redundancy and eliminates the need for intervention operations during deployment. These firing systems have been tested and validated in accordance with API RP-67 Recommended Procedures for Oilfield Explosives Safety and are among the safest and most reliable in the industry.

Baker Hughes perforating solutions are optimized for reservoir conditions and include customized equipment selection with engineered application solutions. The driving force behind solution design is the Baker Hughes PulsFrac modeling tool, the industry’s premier well dynamic-event modeling software. The system models gun shock and dynamic underbalance effects (either intentional or unintentional) before operations begin, enabling engineers to resolve issues before they can become operational setbacks.

The challenging environments in ultra-HPHT wells have discouraged some operators from developing difficult reservoirs. Through disciplined engineering, thorough testing, pre-operational modeling, and exacting execution, the Baker Hughes UltraConnect HPHT perforating solution helps reduce risk, increase production, and enables the harvesting of previously inaccessible hydrocarbons.

Contact your local Baker Hughes representative today to learn more about how the UltraConnect 35K HPHT perforating solution can help you reach new depths in today’s most complex and demanding wells.

CASE HISTORY

An operator in the Gulf of Mexico drilled a well with a measured depth (MD) in excess of 29,000 ft (8839 m), where downhole temperature and pressure were expected to reach up to 470°F (243°C) and 35,000 psi (2413 bar) including the applied pressure required to fire a perforating system.

Baker Hughes worked with the operator to gain a comprehensive vision for the entire project from completion to production. One of the major technological roadblocks they faced was finding a supplier that could develop an ultra-high-pressure, high-temperature (HPHT) perforating system that would fire successfully at 35,000 psi.

Our methodology for developing technologies requires us to extend existing solutions whenever possible. We started with our field-proven firing system and then tested multiple component configurations to improve performance at higher pressures and temperatures.

The hardness of the target formations coupled with extreme pressure presented a huge challenge. We made a significant investment in both time and money, and after months of research and development, successfully tested our DeepConnect? rock-optimized charges and began production of the UltraConnect? 35K HPHT perforating system. We used Baker Hughes PulsFrac? software to model and calculate wellbore behavior, and generated a detailed and comprehensive quality plan that we followed during execution. We shared this plan with the operator, giving them a transparent view of our processes, progress, and testing. This level of cooperation is essential to delivering successful operations, particularly in extreme conditions that require the development of new technologies.

With a plan in place and new components having gone through lab testing, we were finally ready to deploy the UltraConnect 35K HPHT perforating system. The perforating string included multiple guns with a redundant firing system—modified to function at ultra-high pressures—and the new ultra-HPHT DeepConnect charges.

After reaching perforating depth, an absolute bottom hole pressure of 34,500-psi was applied and bled off to activate the time delayed redundant firing system. With a positive indication of gun detonation, circulation between tubing and annulus was confirmed and the assembly was pulled from the wellbore.

The operator was extremely pleased with the Baker Hughes team, from our modeling and planning processes to our ability to enhance proven technology to meet this challenge. Without this innovative ultra-HPHT perforating system, the operator would have had to spend months in research and development, potentially costing millions of dollars. Even greater savings were realized through flawless execution at the rigsite. Most importantly, the Baker Hughes UltraConnect 35K HPHT perforating system enabled the operator to access a previously inaccessible formation.

石油圈

石油圈